Source Measure Units Migrate to Address Expanding Power Applications

What you’ll learn:

- Why SMUs are important today.

- Application spaces using SMUs.

- SMU functionalities.

One of the more important ramifications of an ever-growing tech-based society is the need for power to drive it. The positive aspect about that pressure in terms of power test is that it’s accompanied by the very core technologies fomenting the challenge. Thus, test equipment manufacturers can leverage those very same technologies in their own power-evaluation solutions.

In addition, the digitization of power and the growing functionalities of the industrial IoT present ways to address the means of when and where test can be accomplished. Automated test has been especially empowered by advanced power- and signal-management solutions. One of the most useful tools in power test is the source measure unit (SMU), capable of both sourcing and measuring simultaneously, delivering precise voltage and/or current measurements.

SMUs are and have been useful tools in power engineering since they were first developed in the early 1980s for semiconductor characterization. The growth in utility and functionality of these products also are a testament to the extent semiconductor-based solutions have permeated the marketplace. SMUs address high-accuracy and -resolution applications beyond characterizing and testing semiconductors, testing other nonlinear devices and materials in which voltage and current embrace both positive and negative values.

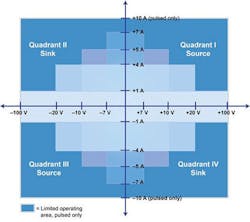

To accomplish that, SMUs have four-quadrant outputs; for characterization, they perform much like a curve tracer (Fig. 1). When used in automatic test equipment (ATE), SMUs are equipped with a computer interface. They can integrate the functionality of a power supply, function generator, digital multimeter (DMM), or oscilloscope while combining a current source and an electronic load into a single instrument.

Serving Many Applications

Other test and evaluation application spaces that benefit from the latest generation of SMUs include solar-cell testing, where the device under test (DUT) is illuminated at a known intensity, then measured for electrical power produced per unit area. For any given solar cell, the output voltage depends on current produced, which is why an SMU is used—it can flexibly change the voltage while simultaneously measuring the change in current.

Another can be found in the evaluation of vertical-cavity surface-emitting laser (VCSEL) systems. Temperature-sensitive, a VCSEL’s emission spectra is changed depending on the refractive index and thermal expansion of the resonator material, leading to output variance and changes in optical uniformity. VCSEL testing needs precise current control so as not to damage both the DUT and the probe being used. In the related space of laser-diode evaluation, cabling and inductance issues may cause the current source to overcompensate, resulting in overshoot and ringing.

The latest SMUs serve myriad other spaces in the power marketplace, especially with speed and precision now being top priorities. For example, Rohde & Schwarz jumped into the SMU arena with two products targeting a variety of evaluation tasks (Fig. 2). The two-quadrant R&S NGU201 performs wireless-device battery tests, among others, and can automatically switch from source to sink mode at a defined positive input voltage, while the four-quadrant R&S NGU401 also can switch at negative voltages.

The instruments incorporate current-feedback amplifier technology that provides both high sensitivity and accuracy to precisely measure currents from nanoamps to amps in one sweep. For rapidly changing load conditions like those in devices switching between sleep and transmit modes, the R&S NGU features an optimized control-loop load providing a recovery time of under 30 μs. The R&S NGU SMUs include six current ranges, from 10 µA with 100-pA resolution to 10 A with 10-µA resolution. For all ranges, accuracy up to 0.025 % is achieved.

Looking Forward

Power electronics optimization is key to enabling the continued advance of modern technology. Any potential areas of inefficiency and non-optimum operation must be eliminated, if only to reduce costs in areas of bandwidth usage, battery life, and safe operation. In reality, every improvement in power-circuit and electronic-device operation provides cascading benefits in every direction, from thermal to financial. SMUs are vital tools in that optimization quest.