A Solution for Testing Battery Management Systems

As the developed world attempts to move to a more green lifestyle, electric vehicles clearly are becoming a growing part of the automotive scene. They promise low or no emissions and conceivably low cost of fuel from the power grid, yet they will deliver us safely to and from work and shopping. But their design is a paradigm shift for the auto industry—new test and validation challenges to the industry as the electronics content of the vehicles grows.

Figure 1. Internal View of a Li-ion Battery Stack Courtesy of Argonne National Laboratory

The auto industry has embraced the use of Lithium ion (Li-ion) batteries for most future hybrids and plug-in hybrids (Figure 1). This battery requires a carefully designed charging system to provide long life and safety.

Accordingly, one of the major challenges of electric vehicles concerns the effective testing of the battery management system (BMS), the electronics that manage the state of the battery storing the high levels of energy required to propel the vehicle. As a result, DMC Engineering and Software Services and Pickering Interfaces have collaborated to help provide a solution to BMS testing based on PXI modules that emulate the battery systems.

Building and Testing a BMS

Manufacturing processes for Li-ion battery cells have a high degree of inherent variation, requiring a more advanced and robust BMS. The BMS must compensate for any underperforming cells in a module or stack by actively monitoring and balancing each cell’s state of charge.

A battery stack design can have infinite combinations of good and bad cells and will be subject to a huge range of environmental conditions. These variations and usage scenarios necessitate battery pack simulation for development and qualification of effective BMSs. They also can influence the type of testing used in a production environment.

The BMS is therefore a critical component of hybrid electric vehicle, electric vehicle, and plug-in electric vehicle electric drive systems. A typical BMS controls all functions of the energy storage system (ESS), including battery-pack voltage and current monitoring, individual cell voltage measurements, cell-balancing routines, pack state of charge calculations, and cell temperature and health monitoring as well as ensuring overall pack safety and optimal performance.

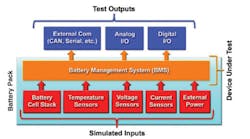

The BMS modules and related submodules must read voltages from the cell stack and inputs from associated temperature, current, and voltage sensors. From there, the BMS must process the inputs, making logical decisions to control pack performance and safety and reporting input status and operating state through a variety of analog, digital, and communications outputs.

Effectively testing a BMS involves two primary functions:

•?Accurately simulating the required sensors and battery cell stack inputs to the BMS.

•?Measuring, collecting, and processing the digital and analog outputs produced by the BMS as a result of those inputs.

Why the BMS Challenge

There are several reasons for validating the performance of a battery stack’s BMS separate from the battery itself. These reasons include safety and longevity.

Everyone has heard horror stories about Li-ion batteries exploding in laptops and cell phones. The good news is that Li-ion batteries have six times the energy density of lead-acid chemistries and three times that of nickel-metal hydride. In addition, more charge/discharge cycles are possible with a properly designed and maintained battery stack. But, any time you pack more energy into a smaller space, with increased usability, your safety concerns likely increase.

The control of the battery’s energy provides electrical power in the form of current and voltage. An uncontrolled release of this energy can result in smoke, fire, explosions, or any combination thereof. All Li-ion systems use an electrolyte that is flammable and has a tendency to undergo thermal runaway. When you heat this material, it will reach an onset temperature at which it begins to self-heat and progresses into fire and explosion.

Uncontrolled energy releases can be caused by severe physical abuse, such as crushing, puncturing, or burning, which can be mitigated by mechanical safety systems and proper physical design. However, they also can be caused by shorted cells, abnormally high discharge rate, excessive heat buildup, overcharging, or constant recharging, which could weaken the battery. These causes are best prevented by a properly designed and validated BMS.

The BMS also is responsible for tracking a battery pack’s exact state of charge, which is critical to maintaining its usable life. Usable battery life can be dramatically reduced by simply charging the pack too much or discharging it too deeply. Accordingly, the BMS must include a very accurate charge estimator.

Since you can’t directly measure a battery’s charge, the state of charge percentage has to be calculated from measured characteristics like voltage, temperature, current, and other proprietary parameters by the BMS. Validating the accuracy of the BMS state of charge calculation is critical

to pack performance and longevity.

Battery Stack Emulation

Li-ion batteries with a lithium iron phosphate cathode and graphite anode have a nominal open-circuit voltage of 3.2 V and a typical charging voltage of 3.6 V. Lithium nickel manganese cobalt (NMC) oxide cathodes with graphite anodes have a 3.7-V nominal voltage with a 4.2-V max charge.

A typical battery stack for automotive applications will use approximately 100 cells in series capable of generating voltages greater than 350 V. High voltages allow energy to be transferred to the drive system with thinner wires and lower losses than would be the case with lower voltage systems. But high voltages need careful management if damage to electronic systems is to be avoided.

Testing and validating a new BMS on a real battery stack are not practical. The consequences of an error are likely to result in significant damage to either the BMS or the battery stack and could hurt the test operator as well. For obvious reasons, the test cannot be repeatedly run with this configuration. Only when confidence is high can the BMS be connected to a real battery stack.

Secondly, faults and the characteristics of a real battery stack cannot be varied to simulate all of the conditions the BMS is designed to handle. Injecting faults, especially in development and new product introduction, can be crucial to successfully validating hardware and firmware designs.

Design Challenges

DMC approached Pickering Interfaces with a request for a product that could simulate a low-power battery stack to validate the BMS design. The battery stack had to be fully programmable for output voltage for each cell and capable of both sourcing and sinking current.

Pickering Interfaces already had experience in designing single-cell PXI-based battery simulators for mobile applications. So following the inquiry, a design feasibility study was undertaken. To keep the systems compact and low cost, it was necessary to pack as many channels on a single module as possible. This made for a compact footprint at a price that could be justified to the auto industry.

Not to be negative, but PXI is not an ideal platform for designing high-density, multicell battery simulators. However, the availability of all of the other modules in PXI to address this test as well as the wide acceptance of PXI indicated a focus on a PXI solution.

Clearly, the end product had to be reliable, compact, and safe to use. A PXI chassis typically can support up to 17 peripheral slots, so the requirement to make the design compact required each single-slot-wide module to simulate six cells of a battery stack, requiring 17 modules in a chassis to simulate a 100+ cell stack. This density places some space restrictions on the design of each cell. The requirement was on an urgent schedule to meet

the end-user project times so, for the most part, components had to be available off-the-shelf.

Each cell had to provide up to 300 mA and generate voltages in excess of 4.2 V. That was a significant challenge for the chassis backplane to supply enough power for each slot and for the system as a whole. A fast transient response to simulate a battery also was needed.

The PXI backplane can supply up to 6 A to each module on the 5-V supply—by far the most capable of the PXI backplane supplies. However, DC conversion from 5 V is notoriously inefficient. For that reason, significant losses had to be expected in the design, losses contributing to the thermal load on the chassis. The solution was to take the power for the cells predominantly from the +5-V supply but to supplement it with power from the +12-V and -12-V supplies.

Each cell of the battery simulator uses a fixed isolated DC-to-DC converter to provide an isolated supply which then is regulated by a fast-acting linear regulator. The fast linear regulator is required to allow the battery to be emulated at a point remote from the PXI supply without introducing poor voltage regulation on the output and without the use of an excessively large output decoupling capacitor.

The linear regulator was needed to shed significant amounts of power under the worst-case load conditions, but clearly each cell on the module was very constrained on space which, in turn, limited the amount of heat sinking available to cool the regulator. The solution to this problem was to use a regulator designed for automotive use that could withstand high temperatures, had built-in thermal protection, and could use the PCB copper surface for cooling. The efficient cooling system in a PXI chassis ensured these copper areas were well ventilated. PXI works very well for this type of application, particularly when the active device is placed low down on the PXI module.

Safety and isolation also presented significant design challenges. In a battery stack, the 96 cells are connected in series. If each cell is set to its nominal 4.2-V output voltage, the result is a potentially lethal output voltage. The isolation barrier had to be designed to withstand up to more than double the common voltage on each cell and yet still have programmatic control of the battery cell.

The proposed design used digital isolators to provide the control interface to the PXI backplane. A safety interlock system was designed to ensure that if a user disconnected the cable assembly from the front of the PXI module either that module or all the modules in the system would close down.

The BMS test also had to simulate a cell being charged. Simple power supplies are unidirectional; they either source or sink current, not both. The battery simulator had to do both, but the sink current required could be much less than the source current.

This problem was solved by integrating a programmable current load in the design that would preload the power supply. When the BMS was being charged, the current load would ensure the power supply was still sourcing current.

All these challenges and solutions were assessed, and a proposal was put together for a new six-channel battery simulator to be designed and supplied by Pickering Interfaces. After the exchange of ideas on modifications to the design and questions to clarify the expected performance, an order was placed for a complete battery stack emulator (Figure 2).

Design and Implementation in the Test System

The first modules constructed became the Model 41-752. The challenges were not confined simply to the hardware design. To test and use the 41-752 required a software support team working in parallel with the hardware design team. First, the team had to develop software to test the module hardware. Then, they had to design software, including manual soft front panels, which could control each cell in each module.

Once this module was shown to have satisfactory performance, the remaining modules were constructed and shipped to DMC. DMC integrated the solution into its test system before shipping it to the end user. After successful trials and some minor adjustments of the design, the user accepted delivery of the module.

Although the use of PXI as the platform generated a number of difficult challenges for this application, the flexibility and speed of design possible with PXI were demonstrated by how quickly the design progressed. The backplane power supplies, the PCI control bus, chassis ventilation system, and PC-based software allowed the design to proceed at a high rate of progress. In the case of the 41-752, from the placement of the order to the dispatch of the first system took eight weeks.

The 41-752, now commercially available, offers six channels of battery emulation for voltages up to 7 V and current up to 300 mA. The high isolation barrier, rated at 750 V, permits many cells to be placed in series on D-type user connectors. A flexible safety interlock allows systems to be connected that are intrinsically safe to use. The Pickering 40-923 chassis provides the power and the current needed to meet the task of emulating a battery stack of approximately 100 cells.

Other Tests Using PXI

In addition to the battery simulator, PXI modules supported the simulation of the temperature sensors, analog and digital I/O, and high-voltage switching of the battery stack output as well as communicating with the BMS via a CAN port. The system consisted of two PXI chassis and some external circuitry. The entire system was a compact unit that fit in a 1.5-meter rack.

Conclusions

In the coming years, we will see more and more electric vehicles on the road, be they hybrid or full electric. To assure long battery life and protect the systems from harm, a BMS will be a very intelligent subassembly. Testing will be critical to ensure that customer expectations are met. For purposes of compact size, cost, and flexibility, PXI test systems can help address these challenges.

About the Authors

David Owen is the business development manager for Pickering Interfaces. Over the last 25 years, he has held key engineering, product management, and strategic marketing positions with Marconi Instruments, then IFR (now part of Aeroflex). Mr. Owen was the named innovator of more than 10 patents in the field of RF signal generation and analysis and has written many application and technical support notes for signal generation and signal switching and management. e-mail: [email protected]

Bob Stasonis is the Americas/Asia sales and marketing director for Pickering Interfaces. Over the last 30 years, he has held technical, sales, and marketing positions with Pickering Interfaces, Teradyne, GenRad, and Schlumberger. Mr. Stasonis is on the board of directors and past president of the PXI Systems Alliance, board member for the LXI Consortium, and the vice president of marketing for the American Society of Test Engineers. e-mail: [email protected]

Brent Hoerman is a senior project engineer at DMC Engineering. He is a certified National Instruments LabVIEW architect and the DMC point-person for battery testing. Before DMC, Mr. Hoerman was a scientist at Structured Materials Industries, a technical staff member for COVEGA, and a process development engineer for Agere Systems. e-mail: [email protected]

April 2010