PXI has blazed a trail since its introduction in 1997 by National Instruments with growth that has remained in the double digits, according to a 2016 Frost & Sullivan report, “VXI, PXI, and AXIe Test and Measurement Market, Forecast to 2020.” Based on commercial-off-the-shelf (COTS) technology from the personal-computer industry and, specifically, the PCI interface widely used in x86 type computers, PCI eXtensions for Instrumentation had one immediate advantage—it was cost-effective. By leveraging powerful, widely available technology, it gave a boost to the plug-and-play environment often described as a “platform” on which innovators have built everything from automation systems to modular laboratory instruments.

The inception of PXI was partly a result of serendipity. In the mid-1990s, National Instruments held its annual internal sales conference every winter in downtown Austin, TX. Three key people from the company were brainstorming a solution that could take the benefits customers achieved from NI’s PC data-acquisition products by porting those functions to the VXI platform that NI was heavily involved in. Many ideas and “what-if” scenarios were discussed, noted Adam Foster, NI senior product manager, Test and RF Systems. The recent announcement of CompactPCI by PICMG (formerly known as the PCI Industrial Computer Manufacturers Group) came up in conversation, and the “aha” moment occurred as the group realized that rather than converting everything over to VXI, it’d be a lot easier to take the instrumentation extensions and openness of VXI and bring that to PC technology, he explained.

NI assembled a team of experts to develop specifications for a new test platform to do just that, and nine months later, NI announced the PXI standard at an NIWeek press conference in August 1997. In addition to the release of the standard, NI also announced the creation of the PXI Systems Alliance (PXISA) with other vendors featured and present at the conference such as GenRad and PXIT, demonstrating that PXI was defined to be an open, industry standard. The announcement even showcased the first PXI chassis and the first five PXI instruments.

While NI entered the market at a run, it soon had company. Pickering Interfaces, for example, was a very early adopter, joining the PXISA in late 1998, said Bob Stasonis, director of sales and marketing for Asia and the Americas and a member of the board of directors for PXISA.

Furthermore, although he was working for GenRad at the time, he said he is the only original signer of the PXISA incorporation papers still involved with PXI. Figure 1 shows initial signers, including Stasonis, Darach Kelly of PXIT, Spencer Stock of NI, and Fred Bode, who served as executive director.

Courtesy of Bob Stasonis and the PXI Systems Alliance

Although Pickering had been very involved in GPIB switching, “Our management recognized that open standard modular test systems are very important to the test and measurement industry,” said Stasonis.

GenRad, Stasonis’s employer at the founding of the PXISA, was ultimately bought by Teradyne. Another company involved in PXI, ZTEC Instruments, also is under Teradyne ownership—having been bought by LitePoint, a Teradyne company. Teradyne now offers the ZT-Series modular waveform generators and oscilloscopes and digitizers in PXI and other configurations, including LXI and VXI.

Another early adopter, Virginia Panel Corp. (VPC) has been a PXISA partner since 1998, according to Jason Diggs, a VPC marketing designer. PXI became a significant focus for VPC when PXI’s instrument cards came on the scene in 1999 through 2001. “The capability to eliminate the need for external PCs from test systems gave our customers the ability to ‘rack and stack’ test components without sacrificing the high-performance peripherals of a PC,” said Diggs. Furthermore, the compactness of having a portable test system in a reduced chassis footprint was ideal for a mass-interconnect design.

But the growth of PXI was tempered by the continued strengths of competing approaches. According to Steve Fairbanks, senior director of products and instruments, Astronics Test Systems, his company joined the PXISA in 2002 when the company was still named Racal Instruments. “We contributed to the PXI consortium as we developed and provided early PXI instrumentation and chassis,” he said. However, the company’s customer base, which is largely the military and aerospace sector, remained committed to VXI investments, and it wasn’t until earlier this decade that customers started to transition to some new PXI-based systems. “In 2014, keeping in step with our customers, we began new PXI instrument development,” he noted.

PXI strengths and benefits

While there are many benefits to the PXI standard, VPC has found the mechanical architecture of PXI to be the most empowering aspect of the standard, explained Diggs. “Since embedded controllers are reliably relegated to the left-most position and the instrument cards are evenly spaced, it allows our engineers to design I/O modules to a 0.8-inch center standard, which provides our customers a consistent engagement and a higher product cycle life for their mass interconnect,” he said. Furthermore, with the cable assemblies all traveling to the same plane on the face of the chassis, it helps to standardize cable length and improve cable management, he noted.

While most VPC customers enjoy the ease of cable solutions, according to Diggs, namely easier repairability, easier design change, and lower cost, some customers are drawn to printed-circuit-board solutions. Diggs said customers appreciate the one-to-one module-to-instrument relationship because it directly connects the I/O module, board, and PXI instrument card, creating a single assembly. “We call these board solutions Pull-Thru Solutions (Figure 2) because they allow the test engineer to remove the entire assembly through the receiver frame as one piece,” he noted. Diggs pointed out that this design prevents the test engineer from having to repeatedly disconnect the board from the PXI instrument card, protecting the card’s connectors from damage.

Courtesy of Virginia Panel Corp.

Broader and more strategic factors drive the enthusiasm at Pickering, according to Stasonis. First, he noted, modular test architectures are key to compact low-cost test system design. Second, multiple vendors within a standard provide more choices for end users. Third, multiple vendors also mean that many companies will focus on their level of expertise, creating products that are best in class, allowing test engineers to choose the best compromise of performance and budget. Fourth, and perhaps most important, “PXI has never rested on its laurels,” said Stasonis. “The specification has evolved several times in the last 20 years to address new test requirements,” he explained. Thus, PXI has stayed relevant to the industry, and that is an important reason why companies keep selecting PXI, he said.

Finally, the fact that PXI is based on the PC architecture allows PXISA members and customers to take advantage of applications developed for the PC. For example, he noted, Pickering’s Support Engineering team uses remote-control applications to take control of a customer’s PXI chassis to diagnose issues without having to travel to the customer or fly their hardware back to us. “This is a great advantage because our time to repair is very short and our team is far more efficient,” said Stasonis.

Citing a similar set of positives, including the flexibility of the architecture, footprint, and the customer’s freedom to choose among multiple vendors as big strengths for PXI, is Mike Dewey, director of marketing at Marvin Test Solutions (MTS). The company, then called Geotest, introduced its first PXI products in 1999. The company had developed a portfolio of ISA-based test and measurement products in the 1990s, but when the PXI standard was adopted in 1998, MTS made a strategic decision: all future card modular development work would move to the PXI platform, and the focus would be on producing PXI systems. “The initial release in 1999 was a broad range of 6U products, including chassis, digital, and switching products. By 2004, we had more than 100 PXI products in the catalog,” said Dewey.

Recent product developments

Since its inception of PXI, NI has crafted a product portfolio of more than 600 modules and continues to regularly announce new developments:

- The NI PXIe-6570 digital pattern instrument delivers test capability for the ICs commonly found in the wireless device supply chain and Internet of Things devices at what the company calls “an economical price per pin.”

- The PXIe 4135 precision, 10-fA-sensitivity low-current PXI source measure unit features four-quadrant operation and sources up to 20 W of DC power.

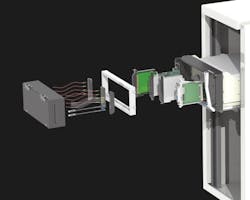

- The PXIe-5840 (Figure 3) is a second-generation PXI Vector Signal Transceiver, part of a new class of instrumentation that combines a vector signal generator, vector signal analyzer, and high-speed serial interface with FPGA-based real-time signal processing and control.

Courtesy of National Instruments

According to Foster, PXI has become a very attractive solution for semiconductor characterization, validation, and product test. “As the devices we use get smarter, they become more software centric,” he said. Thus, NI offers a portfolio of software to accelerate test and measurement across industries with LabVIEW, the flagship software for automated test, Foster explained. Engineers can use interactive soft front panels for out-of-the-box measurements and debugging automated applications, “which delivers all the ease-of-use expected from a traditional instrument,” he noted. Furthermore, he said, NI’s hardware driver software includes a best-in-class programming interface that works with a variety of development environments, such as C, Microsoft .NET, Python, and LabVIEW. The driver also features help files, documentation, and ready-to-run sample programs to assist in test code development. “We also provide application software such as the industry-standard test-management software, TestStand, and real-time test software, VeriStand.”

Pickering, for its part, says it has recently introduced the first PXI-based thermocouple simulator modules (Series 41-760). They are available with up to 32 channels—each channel providing a low-voltage output capable of providing ±20 mV with 0.7-µV resolution, ±50 mV with 1.7-µV resolution, and ±100 mV with 3.3-µV resolution, covering most thermocouple types. It also can be used as a high-accuracy voltage reference (Figure 4).

Courtesy of Pickering Interfaces

“Our first application was for a company designing test systems to monitor large turbines for parameters such as temperatures and vibration,” explained Stasonis. The tester was being designed to detect turbine problems early enough to minimize the possibility of catastrophic failure. “The customer selected our thermocouple simulator to replicate a working turbine as well as create faults to ensure that the system detects them in the real world,” Stasonis said.

“We recognize that in a modular test market we need to work with all major programming environments,” added Stasonis. So Pickering’s drivers are written to support programming languages like LabVIEW and C++. In addition, he said, “We created Switch Path Manager, which makes complex switch routing requirements easier to address and helps speed time to market for test systems.”

Keysight Technologies, also very active, recently announced 10 new PXIe instruments, featuring a new arbitrary waveform generator (AWG) that includes three highly synchronized channels designed for precise tuning of IQ waveforms and envelope tracking and what it says is the industry’s first full-featured PXI oscilloscope (Figure 5). The M9243A PXIe oscilloscope is built with Keysight’s InfiniiVision oscilloscope technology, providing up to 1-GHz bandwidth for quick analysis and troubleshooting of wideband signals. According to the company, with a 1,000,000-waveform-per-second update rate and advanced probing technology, the oscilloscope enables troubleshooting of random and intermittent signals not easily seen with digitizer technology.

Courtesy of Keysight Technologies

The new PXI offering includes AWGs and digitizers that allow engineers to build onto the instrument’s core capabilities or insert custom algorithms into the onboard FPGAs, according to the company. A graphical design environment makes it easy to add customization required for emerging technologies research and design while accessing the full performance and speed of the FPGA. The M3xxxA AWGs and digitizers use the FPGA and PXI reference clock to provide real-time sequencing and multichannel/multimodule synchronization to support advanced multichannel applications like multi-user beamforming technologies and quantum computing.

“Engineers in research are constantly looking for ways to advance technology and achieve new levels of performance,” said Roger Nichols, Keysight’s 5G program manager. “Engineers can generate industry-standard and custom waveforms for the AWG by using Signal Studio, MATLAB, Waveform Creator, or other tools easily integrated into multiple application development environments,” he said.

MTS offers a complete line of PXI products and systems. According to Dewey, the lineup includes the broadest offering of PXI/PXIe chassis in the industry, including 3U, 6U, 3U/6U (combination), PXI, PXIe, and a ruggedized chassis (the MTS-207).

“Our most recent releases are the GX7017 GENASYS subsystem and the TS-960e, a PXIe semiconductor test platform,” he noted. The GENASYS GX7017 chassis is based on the 6U PXI standard and accommodates the GENASYS switching architecture that combines high-density switching with maximum flexibility as well as a high-performance digital subsystem. Key features of the GX7017 include support for up to nine GENASYS switching modules; up to eight GX5960 digital modules; an integrated MAC Panel SCOUT mass-termination receiver providing a reliable, wireless interface; and integrated, high-level switching software.

The TS-960e semiconductor test system (Figure 6), which was introduced in September 2016, features PXI Express performance and expanded test capabilities for RF device and SoC applications. “The 21-slot TS-960e builds on the integrated architecture of the TS-900 platform and accommodates PXI-1, PXIe, and hybrid slot compatible modules—providing an open-architecture test system that offers performance digital, mixed-signal, and RF test capabilities in a compact, single-chassis footprint,” explained Dewey.

Courtesy of Marvin Test Solutions

VTI Instruments, which offers digitizers, core switching, programmable resistor ladders, digital I/O, and DMMs, introduced the SMX Series core ATE switching modules in October. According to Jon Semancik, product line manager, the SMX series offers superior signal-path shielding and delivers 30x better isolation than comparable products, reducing electrical noise and interference, thus improving system level measurement accuracy, decreasing errors and intermittent faults. Software-configurable multiplexer and matrix cards let users change the card format on-the-fly, allowing a single card to perform the function of many, reducing overall system cost, size, and complexity, he explained. All cards have industry-standard IVI drivers for Windows and Linux, he added.

Astronics Test Systems offers a variety of source generation and signal analysis instruments (Figure 7), according to Fairbanks, including the PXIe-1803 digitizer. “This new digitizer provides massive functionality in a compact form factor,” he said. It also offers the best speed and performance available for input frequencies up to 175 MHz along with exceptional signal integrity, high density and modularity, and channel synchronization options, he noted.

“Our PXIe-1802 AWG is well-suited to semiconductor test, whereas the PXIe-2461 FTIC serves a variety of applications in avionics,” he said. The PXIe-3352 Rubidium is built to test any RF application, such as communications or navigation. Both the PXIe-1803 digitizer and the PXIe-6943 digital test instrument are general purpose. The digital instrument also is useful for backplane emulation.

Courtesy of Astronics Test Systems

PXI—a bright future

According to Semancik at VTI Instruments, “The PXI architecture, simply stated, leverages many of the advantages found in prior open-platform architectures—VXI and VME, for example—and implements these in a smaller COTS form factor to gain reduced cost and size.

“PXI is a living, breathing standard based on current computing architecture,” noted Fairbanks at Astronics Test Systems. The benefits include increased speed and bandwidth, “… which is important for the exponentially growing amount of data we are analyzing in test,” he said. The newest generations of the PXI backplanes now can handle this large amount of generated data. In addition, he noted, the PXI cards are smaller, more portable, and affordable, “which opens the door to even more portable test applications in this increasingly mobile world.”

For more information