High-frequency 5G wireless infrastructure requires a new approach to PCB manufacturing

Much has been written about the impending global rollout of 5G wireless infrastructure, and the profound impact that it will have on everything from mobile phone connectivity and fixed-wireless services to transportation, industrial, and entertainment applications and beyond. Providing the ability to deliver 10X faster data rates—with a roadmap to 100X faster speeds—and the capacity to handle 1,000X more data traffic, 5G will enable a unified connectivity mesh encompassing people, autonomous vehicles, IoT devices, industrial machines, and civil infrastructure.

With faster download speeds comes lower latency, and this is essential in applications where near-real-time system responsiveness is required. This will affect the seamlessness of augmented-reality and virtual-reality (AR/VR) experiences, the precision of machine-to-machine (M2M) communications, and the productivity of industrial infrastructure. Perhaps most importantly, ultralow-latency 5G wireless will enable safer transportation via improved connectivity among autonomous vehicles and roadway/airway sensors—where passenger safety is concerned, every millisecond of vehicle response time is critical.

For these 5G-driven applications, the margin for error is impossibly small, and yet the risk of system malfunction or communication failure grows exponentially larger with every new electronic device connected to the network. At the device level, this means that every individual PCB must be subjected to higher standards for performance and quality to help ensure real-time 5G communication continuity. While different technologies and processes are being developed to address these challenges, PCB suppliers are rethinking their production processes with an eye toward new manufacturing systems that improve quality assurance while simultaneously boosting production efficiency.

Signal-integrity challenges

The higher frequencies inherent to 5G pose a key challenge to PCB manufacturing, and this challenge is compounded by the shrinking form factors of electronic devices. The

high-density interconnects (HDIs) designed into these compact devices require thinner traces to maximize I/O while minimizing system size. But finer lines can introduce increased risk of signal degradation. If the line’s physical characteristics—for example, width of the top and bottom—vary in any way from the intended design, RF signal transmission can be delayed by milliseconds, with cascading consequences across the signal chain when signals are not synchronized.

High-frequency signal integrity depends on strict impedance control within the narrow geometries of the PCB trace—impedance is affected by the line’s cross-section dimension, shape, line/space width, and dielectric material. The trapezoidal-shaped cross sections common to traces formed using conventional subtractive etching processes can introduce myriad impedance anomalies. The evolution of modified semi-additive processes (mSAP) has helped neutralize this issue, enabling traces to be formed with greater precision, yielding a line with straighter walls that allows for more predictable impedance control.

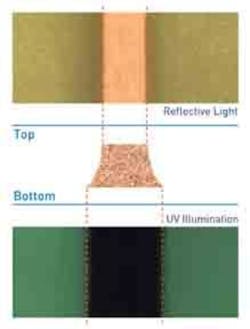

Whether using mSAP or conventional methods, automated optical inspection (AOI) tools must be employed to inspect PCBs for various defect types, from critical shorts and opens to copper surface defects. Until now, AOI’s main purpose was to inspect the CAM design, ensuring it was accurately mass produced and conformed to the design rules. This is insufficient for today’s PCBs, which require higher impedance control whereby the physical characteristics of the actual lines/conductors play a more critical role. Today, only a few AOI tools have measurement capabilities and measure only the trace width at the top of the conductor, completely ignoring the width at the bottom. In order to support the above, the top and the bottom measurements must be taken. Up until now, these measurements have always been taken manually by microscope—a cumbersome offline process that slows production considerably. As a result, it is normally applied to only a small sampling of panels, leaving the majority of the panels untested.

As electronic devices become more and more functionality-rich in a smaller footprint, they require advanced PCB manufacturing that enables HDIs in the form of laser vias (LVs), for example, which are essential for accommodating increasing amounts of I/O. Just as HDIs and flexible PCBs require finer lines to conserve space, they also require smaller vias with higher density design for connecting board layers. Currently, PCB manufacturers will run low-rate sampling inspection on the LVs immediately after the drill stage (DLD, or direct laser-drilling). It will be necessary to inspect 100% of the panels also after patterning for LV defects caused by the plating process to ensure the process quality and higher yield. At this time, the capabilities required to inspect the fine-lines pattern and small vias in a single scan are not cost-effective and not typically supported by conventional AOI systems.

Advancements in AOI

To date, PCB manufacturers seeking the aforementioned AOI capabilities—and other capabilities like pattern inspection or multi-image verification—have had to cobble together an assortment of solutions and tools, which introduce significant process inefficiencies and sacrifice valuable space on the manufacturing floor. To make things worse, production often grinds to a halt anytime a panel is sampled for manual microscopic measurement. Considerable time may be lost here—and time will be an especially precious resource for PCB manufacturers racing to establish leadership positions amid the massive 5G market opportunity.

Fortunately, with continued innovation in AOI technology, these challenges can be overcome. PCB manufacturers have recently gained the ability to automatically inspect and measure PCBs’ top and bottom trace conductors by leveraging 2D metrology technology (Figure 1). This ensures optimal line shape and width and subsequently enables improved impedance control for high-frequency 5G devices. This testing can also be performed uniformly at high throughput rates at a high sampling rate, resulting in better overall yield for the manufacturer.

AOI system integration is advancing, giving PCB manufacturers the ability to combine AOI processes like pattern and laser via inspection or trace and pad measurement on a single platform with a smaller physical footprint. The time and labor savings that can be achieved through a smart, technologically advanced AOI system consolidation where multiple functions are performed by a single AOI solution are substantial, as is the associated throughput boost. Individual AOI functions can also be consolidated leveraging new single-scan inspection technologies that can analyze multiple images simultaneously to improve defect detection rates for patterns and laser vias.

Verification process improvements

Verification processes can now be seamlessly integrated into the AOI workflow as well, precluding the need for additional standalone systems to identify and distill PCB defects from false alarms. This is especially important, given that verification processes can be considerably more resource-intensive than inspection processes, by ratios as high as 3:1. For demanding applications like 5G that impose more stringent verification and quality requirements, manufacturers using conventional heterogeneous AOI tools will need to employ more verification stations, consuming more floorspace, manned by more operators than is required with newer generation integrated AOI platforms—with significant cost increases.

With the new approach, advanced artificial intelligence (AI) capabilities are employed to inspect images and filter out false alarms from real defects at the front-end of the process, automatically eliminating a large number of the false alarms in advance of operator inspection. On the back-end of the process, additional automation can enable the operator to view several images simultaneously on a single display, with false alarms like organic material and oxidization pre-identified onscreen in color-code classifications. This enables the operator to quickly eliminate all remaining false alarms and identify the defects that require shaping via automated optical shaping (AOS) systems.

By automating and tightly integrating verification processes within a unified AOI workflow, manufacturers are spared the time and expense of moving each individual panel to one of many verification stations and administering video images one by one. Instead, all of this can now be done in a single, centralized Remote Multi-Image Verification (RMIV) station, remotely located anywhere in the factory. As an additional benefit, by eliminating the handling required to transport each panel and load it on and off an inspection table, the risks of physically damaging the panels are greatly reduced.

Data analysis and device traceability

A secondary benefit of AOI system consolidation is that valuable production data can be sourced, aggregated, and analyzed much more efficiently than with heterogeneous AOI systems on the factory floor. Single-sourced data gives PCB manufacturers the ability to quickly extract relevant information and distills valuable insights, which in turn promotes faster, more-informed decision making.

Integrated AOI workflows also make it easier to barcode and trace PCBs throughout the production process, identifying and cataloging when, where, and how each PCB was handled. With a complete record of the production process, manufacturers have the ability to identify and isolate defective PCBs early—long before they’re built into the end device, improving the process as well as boosting yield.

Preparing for 5G

It will take some time before the full promise of 5G connectivity is realized. Testing and trial deployments are now underway, with limited commercial deployments targeted for later in 2018. But wider-scale commercial deployment likely won’t begin until 2019 or later. Myriad regulatory and technology challenges must still be resolved for 5G to achieve mainstream adoption.

In the meantime, every participant in the 5G technology value chain is preparing for massive market transformations, from wireless operators and smartphone and autonomous vehicle OEMs to electronic device and PCB manufacturers, and far beyond. The enormous volumes of data set to deluge 5G network nodes—including critical data affecting public safety and industrial productivity—demand that we pay careful attention to quality assurance from network to system to component.

Leveraging advanced, integrated AOI technologies, PCB manufacturers targeting high-frequency, low-latency 5G systems can take advantage of faster, higher-precision PCB inspection and verification and improved PCB traceability throughout the production process. The resulting manufacturing and cost efficiency benefits will enable PCB manufacturers to sharpen their competitive edge in advance of what will be a massive and sustained 5G infrastructure build-out.

About the author

Benny Solomon is the automated optical inspection (AOI) and automated optical shaping (AOS) marketing director for Orbotech’s Printed Circuit Board division. Solomon has nearly 30 years of experience at Orbotech in a variety of product development and marketing roles for the PCB industry. He spent more than 12 years in Hong Kong and Germany as marketing director for Orbotech Pacific, gaining first-hand experience in PCB production technologies, challenges, and developments. He graduated from the Advanced Industrial Marketing Strategy (AIMS) program at INSEAD Business School, Singapore, holds a BA in Business Management from University of Derby in Israel, and a holds a degree in Practical Engineering, Electronic, Instrument & Control from ORT Yad-Lebovitch Netanya Technological College.