Advantest highlights test and handling systems at SEMICON West

Advantest chose SEMICON West to highlight three recently introduced systems: the FVI16 floating power source for the V93000 test platform, the M4171 automated IC handler for use in semiconductor engineering labs, and the T5503HS2 memory tester.

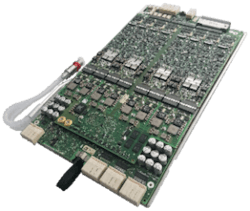

The FVI16 floating power VI source extends the performance of its V93000 single scalable platform for testing power and analog ICs used in automotive, industrial, and consumer mobile-charging applications. It can supply 250 W of high-pulse power and up to 40 W of DC power.

“Our enhanced power resource gives the V93000 platform the industry’s best VI signal performance and expands its coverage into new markets, making it the broadest test solution available,” said Hans-Juergen Wagner, senior vice president, SoC Business Group at Advantest. “With the FVI16, this versatile test platform is equipped for testing semiconductors for a wider range of power-management devices, from airbags and ABS (anti-lock braking system) controllers to USB-C chargers and cordless power tools.”

Derek Floyd, director of business development for V93000 power, analog, and controller solutions, explained that the system includes a digital feedback loop design that provides the best source, measurement accuracy and analog/power performance on the market, compared to competitors’ systems that operate with a traditional analog feedback. Digital feedback technology offers features including spike-free “smart connections” with constant Kelvin monitoring for reliable and precise measurements. User-controllable slew rate and bandwidth settings allow fast settling times adapted to the respective load conditions.

The FVI16 enables high instrument channel density, enabling small system configurations that fit into Advantest’s A-Class test head. Sixteen channels with 4-quadrant operation allow for source-ganging of up to 155 A per card for high-current tests. For high-voltage testing, source stacking of up to +180 V per card within a floating range of + 200 volts can be achieved. The FVI16’s patented integrated fast current clamp protects the loadboard hardware, probe card pins, and DUT sockets, in case a damaged device creates a short circuit.

Customers can use the new FVI16 to extend the capabilities of their existing V93000 Smart Scale systems to the higher voltages, increased channel count and power demands for high-site-count IC testing while maintaining a low cost of test.

Floyd said the FVI16 is already in use at several customer sites and has generated multiple orders from automotive customers in Europe and Japan. He added that the V93000 platform is serving an extensive list of automotive test applications, from headlamp drivers and infotainment devices to ADAS controllers and 77-GHz radar.

The M4171 handler meets the mobile electronics market’s needs for cost-efficient thermal control testing of ICs with high power dissipation during device characterization and preproduction bring up. The portable, single-site handler automates device loading and unloading, thermal conditioning, and binning in engineering labs, where most testing today involves manual device handling, according to Zain Abadin, director of handler product engineering. The handler also features an active thermal control (ATC) capability typically available only on larger footprint, more costly production-volume handlers, Abadin said.

He added that the M4171 can be accessed remotely to conduct device handling and thermal control from anywhere in the world through a network connection. A camera installed inside the handler can check system status.

The handler offers wide-temperature ATC capabilities from -45°C to 125°C, and it can support multimode test processes (single-insertion multiple-temperature), automated testing, automatic ID testing, output tray retesting, and manual testing, both predefined and user-defined. The system uses direct device-surface contact, which enables quick temperature switching for fast ramp-up and ramp-down and improves cycle temperature testing by over 40% compared with manual thermal-control solutions, Abadin said.

The M4171 handler is compatible with the V93000 and T2000 platforms as well as other testers. Other features include a 2D code reader, a device rotator, and a high contact-force option.

They traced the history of key applications drivers for DRAM, noting that the original T5503, at 2.133 Gb/s, covered DRAM used in PCs, servers, and feature phones, while the next-generation T5503HS covered smartphones, tablets, and HD gaming. The new T5503HS2, at 8 Gb/s, will address datacenter, high-performance-computing (HPC), AI, and deep-learning applications as well as automotive ADAS, self-driving cars, virtual reality, 5G and LTE smartphones, and ultra-HD TV.