Courtesy of ANSYS

The car is becoming more of an electric machine than the mechanical machine that it has been over the past century, according to Sandeep Sovani, Ph.D., global director, automotive industry, ANSYS Inc. As this evolution progresses, simulation is playing an increasingly important role in the development of a vehicle—whether it’s used to commute to work for 10 years or to “race to the clouds” in less than 10 minutes.

In a recent phone interview, Sovani described simulation’s role in advanced vehicle technology, focusing on the battery by way of example, and he described ANSYS’s role in Volkswagen’s record-breaking run June 24 at The Pikes Peak International Hill Climb. He also commented on simulation’s role in logging the billions of virtual miles necessary to prove the safety of autonomous vehicles.

Sovani said he sees three major trends driving innovation these days. “The first, obviously, is the move toward autonomous vehicles,” he said. “The second is electrification—not of just the drivetrain but steering systems, pumps, and many other components as well.” The third trend he calls “electronification,” but adds that it could also be described as the integration of “smart products.” “New, smarter devices are coming into the vehicle,” he said, including augmented-reality displays, new infotainment systems, and wireless connectivity. This last, he said, is not just for humans but for components within the vehicle to talk to each other. In addition, the wireless connectivity and the cloud networking bring about concerns over cybersecurity, he said.

Sovani noted that a vehicle’s electric powertrain is made up of components—a motor, power electronics, and a battery or even fuel cell, for example, each of which can be simulated and optimized with ANSYS tools. Subsequently, the components are combined into a system, which also must be optimized. “We offer various tools for comprehensively addressing all the engineering aspects both for the component and system development of the electric powertrain,” he said.

Optimizing the battery

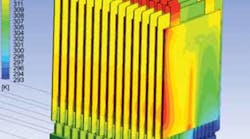

Sovani cited as a specific example the battery, including the electrochemicals, usually in the form of gels, that form the electrodes with positive and negative polarities. The resulting electric fields are not in isolation—they coexist with thermal fields, which also must be taken into account.

At the module level, he said, it’s necessary to analyze and optimize the cooling-channel strategy. All cells should remain as close to the same temperature as possible. Otherwise, he said, internal currents may result from one cell discharging and charging another, without the battery doing any useful work. “Thermal management is crucially important, and we provide complete tools for thermal management,” he said.

He added that many of the tools ANSYS provides for battery simulation employ the finite-volume method used in computational fluid dynamics. As simulation moves from the component level to the system level, he said, reduced order modeling comes into play. It retains nearly the accuracy of the high-fidelity physics simulations, yet can run 1,000 times faster than real time, he explained.

Sovani also commented on mechanical aspects of the battery. The battery holds an enormous amount of energy, and it’s necessary to understand what can happen if the vehicle gets into a crash or a nail penetrates a cell. In addition, the batteries are subject to vibration as the vehicle operates, so it’s necessary to understand the effects of the vibration on the batteries and the mountings that hold them in place. “We do mechanical analysis of the battery from many different perspectives—the electrode level, cell level, module level, and pack level,” he said, adding that it’s also important to analyze the busbars carrying currents inside the batteries.

Embedded software

In addition, he commented on safety-critical embedded software. “We provide model-based software development tools that are qualified to the ISO 26262 standard all the way to the ASIL D level, and these model-based tools generate safe and robust certified code for the battery-management system,” he said. He added that another issue is functional safety. He said ANSYS provides functional-safety analysis tools that identify possible failure modes in the battery, allowing engineers to make modifications and perform design verification to ensure that the modifications are successful.

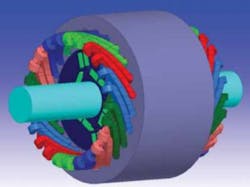

Sovani said the analysis he described in detail for the battery applies to all other aspects of the vehicle, including the motor , for which the company provides tools to simulate the magnetics, thermal and structural aspects, reliability, efficiency, and even acoustics—extending from the component level to the system level.

“A rule of thumb is that individual optimized components don’t create an optimized system when put together,” he said. “The components have to be matched at the system level, and the system has to be put through its own tests,” to determine how it will respond in the field—when required to brake rapidly, for example, or operate in very cold temperatures.

Consequently, the component models are brought together into a very large physics co-simulation, showing the components interacting with each other—the battery, motor, powertrain controller, and software, for example. Subsequently, reduced-order models can enable faster simulations at the system level—to determine how the vehicle would respond to 10 hours of traversing hills and various temperature conditions, for example.

“That drive cycle simulation can be done very rapidly with these reduced-order models,” he said. “The reduced-order models typically have very high accuracy—not as accurate as the high-fidelity physics, but for the battery, for example, we see only about a 2 or 3% error with the reduced-order models that run 1,000 times faster.” He said the company uses some special techniques, including the linear time invariant method, to retain the accuracy of the high-fidelity physics as much as possible in the reduced-order models.

Pikes Peak International Hill Climb

Sovani put his comments in the context of a real vehicle by describing The Pikes Peak International Hill Climb and ANSYS’s role in providing simulation technology for Volkswagen’s all-electric I.D. R Pikes Peak racecar. He commented that the event has served for decades as a proving ground for new technologies. Over a 12.4-mile course with hairpin curves, a vehicle ascends 4,700 feet to a final elevation of 14,100 feet. “ANSYS partnered with Volkswagen Motorsports, and we helped them in the design of parts of the electric powertrain for this race,” he said.

“This vehicle presents unique challenges compared to road vehicles,” he said. “First are the extreme altitude and temperature changes, and even the density of the air changes significantly from the bottom to the top, all in a matter of minutes. However, the I.D. R racecar has to be optimized for its 10-minute or so run, whereas a road vehicle has to be optimized for 10 years or so.” Yet despite the differences, from a simulation standpoint, the same methods can be used to test the I.D. R Pikes Peak as are used for a road vehicle, he said. It’s simply a matter of changing some operating conditions—or essentially changing some numbers in the simulation tool.

“That’s the beauty of simulation,” Sovani said. “The alternative would be to build mechanical prototypes that must be tested in wind tunnels that can reproduce the low air densities and cold temperatures expected on Pikes Peak.”

With regard to simulations of the I.D. R Pikes Peak, he said, “We made some astounding discoveries that helped Volkswagen Motosports significantly optimize the cooling system for the battery and improve the aerodynamics of the vehicle.” Unfortunately, he couldn’t disclose details, but said in general that vehicle weight and aerodynamics are key factors. “The less amount of air that we draw in for cooling, the better,” he said. “The more air drawn in for cooling the battery, the more the drag on the vehicle.”

The simulation efforts to optimize weight, cooling, aerodynamics, and other vehicle characteristics have paid off. They helped contribute to racecar driver Romain Dumas piloting the I.D. R Pikes Peak through the hill climb in 7 minutes and 57.148 seconds, setting a course record by 16 seconds.

Courtesy of ANSYS

Although Sovani couldn’t disclose many details about the project, Volkswagen has publicized some information about the I.D. R Pikes Peak. Two electric motors deliver a combined 680 hp and 479 lb.-ft. of torque, allowing the I.D. R to go from 0 to 100 km/hr in approximately 2.25 seconds. The 40-kW lithium-ion battery was designed to be lightweight and fast-charging—the latter because a run can be interrupted by bad weather and restarted as soon as 30 minutes later. And I.D. R’s brakes were designed to recover approximately 20% of the energy needed to complete the run. Finally, Dumas commented that the electric vehicle is a good match for the mountain because “the power remains constant” despite the decreasing air density over the course. He said combustion-powered vehicles “lose a significant amount of power in the thin mountain air.”1

Autonomous vehicles

Sovani then discussed autonomous vehicles. “The crucial thing is that they are very heavy objects moving at high speeds in the vicinity of humans, so they have a tremendous potential to cause damage,” he said. “The main challenge is making them safe.” He continued, “Essentially we are creating a machine and letting that machine loose among humans to operate for hours and hours or days and days on end without any intervention from a human driver. Throughout those days and days of driving, the machine will encounter many, many conditions that it must handle successfully on its own.”

Courtesy of ANSYS

Sovani described a safety triad. One part is functional safety, which involves looking at what could possibly go wrong through methods such as fault-free analysis. He cited as an example a camera, which has a particular sensitivity to light and to color. The camera may identify a pedestrian in a crosswalk, but should the pedestrian be wearing a particular color of clothing, or should the scene be backlit by the sun, the camera may not be able to understand what is going on, leading to failure. For the camera, he said, ANSYS provides tools extending from simulating the optics to simulating the perception software that runs on the camera’s ECU, to which ANSYS tools can provide simulated imagery, bypassing the optics and the CMOS image sensor.

Another aspect of the triad involves creating safety architectures for software, which is particularly important for machine-learning systems. “Most of the software written for cars today is rules-based software,” Sovani said. “If this happens, do that; if you get that input, do this. There may be millions of lines of software, but it essentially follows logical rules, and it’s easy to know how the system is going to behave.”

But the neural networks in autonomous networks are essentially behaving like the human brain. In response to an input, “The output is not based on any logic as such,” Sovani said. “It’s based on the different pathways in the neural network and the weightings of the different pathways.” If a camera mistakenly perceives a stop sign as a speed-limit sign, for example, there is no backward traceability to help determine how the error occurred. The problem can be addressed through techniques such as building a monitoring system into the neural network, he explained.

The last but certainly not least aspect of the safety triad, Sovani said, is safety validation, which involves running the vehicle for literally billions of miles through all the different conditions it can be expected to encounter. He cited Waymo’s recent announcement that it had logged a total of 8 million miles of physical road tests.2 At the rate Waymo and its autonomous-vehicle competitors are conducting physical road tests, reaching the 8.8 billion miles3 that might be necessary to prove out the technology is not practical.

“Simulation is literally the crucial piece that is needed to validate the safety of autonomous vehicles,” Sovani concluded.

References

1.“A VW Electric Vehicle Races to a History-Making Win,” Volkswagen, June 2018.

2. Hawkins, Andrew J., “Waymo’s autonomous cars have driven 8 million miles on public roads,” The Verge, July 20, 2018.

3. The future is 8.8 billion miles away, Infographic, ANSYS, 2017.