What is it?

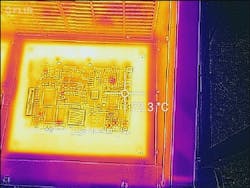

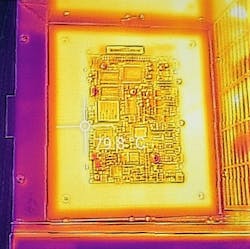

A Temperature Chamber, also known as an environmental test chamber, performs thermal tests through the use of convection. They typically use a fan for forced air convection, like a convection oven used in your house; however, instead of making cookies you are testing products and equipment.

Not so fast

These “ovens” rely on the fans to move the air past the device under test for heat transfer. Therefore, if you want better performance you are going to need more airflow. Increasing the airflow comes at a cost since the unexpected heating from the air friction is significant. Also, more power is required for the test (e.g. operating costs go up) and then there will be increased noise and system wear as well.

Thermal cycling is often a more controlled rate, alternating between the two temperature extremes. The speed of transition can be adjusted to limit thermal stresses and allow guarantee of parts achieving the temperature. There are hold times called soaks at specified temperatures to make sure the parts achieve the expected temperature. Faster ramp rates are usually better in production but on the other side, care must be taken to not stress the parts beyond what they are able to withstand.

Burn-in test is typically a sustained hold at a given temperature (usually hot) to verify operational parameters of a device in a specific environment over time.

Thermal shock, on the other hand, is taking the component from one temperature extreme and another and “shocking” it with very rapid transitions.

This is completed with testing chambers or thermal platforms that either automatically transfer the component being tested from one hot chamber to another nearby cold chamber or simply by using high-performance heaters and cooling in a single chamber zone. As you can see, there is a little more to it than a convection cooking oven.

Another important thing that should be considered is meeting industry standards of testing. A lot has been written over time regarding appropriate environmental testing and most choices will depend on the intended destination for the product. There are some industry standards that are used as rules or guidelines for testing that can be adapted to other needs. The environmental chamber or thermal platform will allow you need to ensure it meets the standards of the application it will be used for. For example, MIL-STD-810, Environmental Engineering Considerations and Laboratory Tests, was designed originally for products entering the defense industry. However, this standard is routinely used for commercial products, too. This standard covers a wide range of environmental conditions such as thermal shock testing, exposure to high and low-temperature extremes, and humidity. Thus, depending on what environment your product will operate in, there is a good chance you will be using MIL-STD-810 for environmental simulation in the design phase to ensure quality and reliability.

John Booher is chief technology officer at Total Temp Technologies.

This article was originally posted by Total Temp Technologies here