Special Report: DAQ Vendors Combine Fast Sampling, Wide Input Ranges, Ease of Use

>> Evaluation Engineering Resources

.. >> Library: TechXchange

.. .. >> TechXchange: Data Acquisition

Download this article in .PDF format.

Vendors of data-acquisition systems are addressing increasingly complex customer applications by introducing systems that offer fast acquisition rates as well as wide input ranges across multiple channels. In addition, they are offering a choice of resolution, data-analysis, and storage options. Applications extend from low-voltage IoT and IIoT sensors to SIGINT and electronic warfare.

Specific products extend from portable data recorders and loggers to open-architecture COTS FPGA board-level products. Many companies are augmenting their DAQ systems with ease-of-use features such as touchscreens and intuitive software.

Products/features

“As customer applications become increasingly complex, DAQ systems must keep up,” said Jamie Pederson, product marketing manager at B&K Precision. “This means faster sampling rates to capture transients, lower voltage ranges for small sensor signals, and higher voltages for measuring higher power systems.”

But the variety of manufacturers in the market, each offering multiple solutions, can present challenges. “It can be confusing for customers when trying to determine which product meets their needs,” Pederson said. “B&K has addressed this by clearly defining each product and providing tools that help the end user select the best recorder for their application.”

Pederson identified a trend in the data-acquisition industry toward touch displays, wider input voltage ranges, and increased integration of measurements, calculation, and analysis. “All of our instruments feature an easy-to-use touch interface for menu navigation and on-screen data analysis,” he said. “We’ve also included the ability to write custom functions with an intuitive script editor for creating math functions applicable to multiple channels. Our wide range of input voltage ranges, combined with fast sampling rate and deep memory, help capture events that are often missed by other recorders.”

Pederson said B&K Precision offers a full line of data-acquisition recorders and loggers with large touch displays and batteries for portability and power-loss backup. “Our DAS220-BAT and DAS240-BAT both feature a 1-ms sampling interval, 16-bit resolution, 100-V maximum input, and up to 15 hours of battery life,” he said. “The DAS220-BAT has 10 built-in channels for maximum portability, whereas the DAS240-BAT is expandable from 20 to 200 channels.”

Pederson described the company’s DAS30/50/60 as high-speed multifunction recorders with a sample interval of 1 µs in memory mode, an input rage of ±5 mv to ±500 V, 64 GB of solid-state memory, and 9.5 hours of battery life. “Users can choose from two, four, or six input channels and a thermal printer as an option,” he said. “These instruments are capable of measuring signals from small sensors to large electrical systems and analyzing single- or three-phase power networks.”

In addition, B&K Precision recently released its DAS1700 high-speed data-acquisition system. “This instrument features four types of measurement boards that can be installed in the base unit in any combination of up to three boards or up to six boards with an optional expansion,” said Pederson. “These boards include a universal input with a maximum voltage of up to 500 V and six channels, a high-voltage board for up to 1,000 V and six channels, a strain-gauge board with six channels, and a multiplexed board with 12 channels. The sampling rate is 1 µs in all memory modes, with a 14-bit resolution for universal and high-voltage boards or 16-bit resolution for multiplexed and strain-gauge boards.” He added that options include CAN and LIN inputs and a 2-TB SSD.

Pederson added that B&K Precision offers software tools for remote setup and control as well as post-acquisition analysis. “Data can be displayed in real-time and displayed in a numerical or graphical format,” he said.

Keysight offers data-acquisition products including the 3-slot, mid-range DAQ970 Series, which comes with flexible interfaces and a range of plug-in modules, according to Bernard Ang, product marketing. “The DAQ970 Series now comes with a new solid-state switching multiplexer to scan up to 450 channels per second and a new four-channel simultaneous digitizer module that allows sample signals up to 800 kS/s per channel,” he said.

Ang added that Keysight’s larger-scale, 8-slot 34980A data-acquisition system provides a scan rate of up to 1,000 channels per second and a choice of mix-and-match plug-in modules. “This standalone mainframe offers fast time to insight, measuring multiple signal types and sensors,” he said. “You can easily configure and run, with no programming.”

Keysight also offers PXI and USB products. The industry-standard modular M9000 PXI Series provides the flexibility, compatibility, and performance required for demanding applications, Ang said, while the U2000 USB Series offers the flexibility to be used as standalone products, or modules can be plugged into a chassis to make synchronized measurements.

Ang also commented on software. “Keysight’s Pathwave BenchVue data-acquisition software helps to control our DAQ970 Series, U2000 USB Series, and 34980A data acquisition systems remotely,” he said. “This software runs on a PC and can, therefore, take advantage of the resources of a PC. It can configure and control multiple DAQ systems and other types of instruments together, synchronize data capture, stream data into PC storage as the DAQ system captures data, and provide test automation, without the need for programming. Everything can be completed through a point-and-click graphical user interface. It can display trend charts, time-domain charts, frequency domain charts, bar charts, histograms, and more, for data analysis work.”

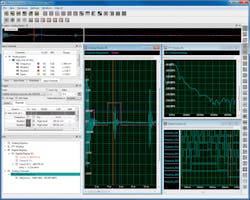

Iversen, Burrows, and Bassett said that NI also provides application and test operations software to accelerate data search, access, and normalization for root-cause analysis. “DIAdem is a robust application software designed for engineering data inspection and analysis,” they said. “It’s purpose-built for test and ships with commonly used engineering analysis functions and visualization tools out of the box. Additionally, through our DataPlugin technology, engineers can normalize data in over 1,200 formats, removing barriers that closed solutions introduce to the engineering workflow.”

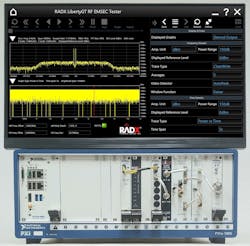

RADX offers DAQ products that build on National Instruments’ technology. “RADX has developed the LibertyGT suite of COTS, modular, real-time, software-defined turnkey DAQ solutions that employ the NationalInstruments FlexRIO PXIe-57xx (and PCIe-57xx) family of FPGA-enabled, high-speed serial DAQ products,” said Ross Smith, RADX co-founder and CEO. “The NI PXIe-57xx family includes digitizers, signal generators, and transceivers that include Xilinx Kintex Ultra FPGAs and DDR3. NI FlexRIO PXIe-57xx DAQ modules, combined with RADX Measurement Science Firmware and Software (MSFS), enable users to quickly and efficiently deploy PXIe-57xx-based DAQ solutions, without having to develop their own applications.”

Smith said RADX COTS DAQ solutions are available either as an integrated, turnkey system that is ready “out-of-the-box” or as an “integration kit” that includes RADX MSFS apps and accessories including a 22-in. touchscreen interface that customer can add to their existing systems. “In addition, RADX has developed USB-Controlled Signal Conditioning Modules (SCM3) that provide amplification and attenuation for both RX and TX applications for the FlexRIO products that enable users to easily integrate the FlexRIO modules into their applications,” Smith said.

Measurement Computing Corp. (MCC) offers a range of data-acquisition and datalogger devices, such as the MCC 152 voltage-output and DIO HAT (Hardware Attached on Top) add-on board for Raspberry Pi-based systems. “We focus on ensuring that MCC systems are easy to use, easy to integrate, and easy to support,” said Peter Anderson, general manager. “MCC has seen a huge increase of interest in implementing DAQ and data-logging solutions around low-cost Linux minicomputers like the Raspberry Pi. When paired with a DAQ device, these units provide a perfect platform for edge computing, industrial IOT, agile development, and product prototyping.”

Anderson said, “MCC offers a powerful and attractive yet simple application—DAQami—for data visualization and collection from any USB or Ethernet-based MCC data-acquisition device,” Anderson said. “For customized applications MCC offers DASYLab, an icon-based application development environment for data collection, reduction, and analysis. Both these environments are easy to learn and use—reducing development time and cost.”

Pico Technology offers PC-based data loggers for measurement of voltage, current, temperature, and numerous user-defined parameters, according to Trevor Smith, business development manager. “The loggers are compact devices that connectare to a host computer and powered over a USB or Ethernet interface,” he said. “They are supplied with PicoLog 6 data-acquisition software that enables easy configuration of one or more loggers to capture, display, store and analyze data.”

Smith elaborated on the software. “PicoLog 6 is our main tool for data collection and results presentation,” he said. “It has additional tools such as Alarms, Math Functions and Waveform Annotations. The file system can store huge datasets, limited only by the size of the hard disk or SSD on your computer.”

Smith continued, “At the heart of PicoLog 6 is a robust file system that is resistant to data loss and corruption. If the computer is shut down and rebooted, PicoLog resumes capturing without losing the previously stored data. Data is stored automatically without the need to provide a file name and location—but if you wish to save data to a file, you can, even in mid-capture. This makes it easy to share data with fellow PicoLog users.”

VTI Instruments, a product line in AMETEK’s Programmable Power business unit, offers data-acquisition instrumentation on each of two platforms, PXI Express and LXI, according to Chris Gibson, senior product manager. “The PXIe systems are designed for interoperability with the LXI interface to enable tight integration into hybrid test systems that offer the advantages of both platforms,” he said. The PXIe line includes the EMX-425x and EMX-43xx digitizers with up to four 24-bit, 625 kS/s channels, the EMX-2500 Gigabit Ethernet remote controller with an LXI interface and IEEE-1588 synchronization lines, and the CMX09 and the CMX18 enclosures with up to 18 PXIe slots and 8-GB/s backplane bandwidth.

The LXI product line includes EX1200 Series mainframes as well as switch, sensor-simulator, resistor-ladder, and comparator/event-detector modules. Gibson added that the EX1200 multifunction counter, DAQ, and digital I/O Module offers eight frequency channels, 16 isolated digital I/O ports, and two isolated DAQ channels; it can measure revolutions/minute from a tooth wheel and position and speed from a quadrature encoder signal.

“VTI products also include a set of independent, Gigabit Ethernet, ruggedized, LXI instruments for testing in a wide range of environmental conditions,” Gibson said, including the RX0124 24-channel bridge and strain-gauge measurement, RX0224 24-channel charge-vibration-measurement, RX0424 24-channel IEPE-accelerometer instruments, and the RX1032 32-channel thermocouple measurement system. “These instruments are rated for operation over an extremely wide temperature range of -20°C to +60°C and are capable of withstanding harsh environments such as jet engine test cells,” he added.

Additional independent, LXI data-acquisition instruments employ power-over-Ethernet (PoE) for portable acquisition applications and include the EX1401 16-channel isolated thermocouple and voltage measurement instrument with built-in cold-junction compensation, open thermocouple detection, and 13th-order polynomial linearization for thermocouple voltages in real time; and the EX1403 16-channel bridge and strain gauge measurement instrument with built-in shunt calibration and TEDS support, Gibson said.

Gibson also commented on software. “Customers with sophisticated data-acquisition applications need to write their own software,” he said. “To serve these customers, VTI products provide industry-standard IVI-COM, IVI-C, and LabVIEW drivers. In addition, these products enable customers to work in either the Windows operating system or the Linux operating system, depending on the customer’s preference.”

All LXI modules have built-in web browsers for web-based access using any web-enabled device located anywhere in the world. All modules allow monitoring and control to save significant time during test setup and troubleshooting.

He added, “VTI ExLab, a data-acquisition software package with icon-based setup/control and a spreadsheet-style format, is available for less extensive data acquisition applications. ExLab has a client/server architecture with multiple displays, real-time graphical analysis, and numerous post-acquisition analysis methods.”

VPG offers two brands of instrumentation, according to Anton Chittey, Europe product and sales manager with Micro-Measurements, and Patrick Rule, senior sales manager with Pacific Instruments. “Micro-Measurements instruments including our StrainSmart systems offer turnkey solutions enabling setup in minutes for rapidly changing test requirements, from 1 to 1024 channels. This makes them ideal for small-to-medium test laboratories performing anything from material property tests, PCBA production qualification, automotive, aerospace, and education,” they said. “Pacific Instruments (PI) offers high speed (up to 10Ms/s) and high channel counts (>8,000). In addition, PI [products] have compatibility with third-party control systems and data streams as well as in-rack analog, DSP, and digital outputs for low-latency control and emergency shutdown conditions.”

With regard to data collection and analysis, Chittey and Rule said data is sent to a Windows-based PC over USB or Ethernet. “An optional embedded hard drive inside the DAQ allows for redundant recording and is often desired in destructive testing applications where tests can only be run once,” they explained. “Data is recorded in raw A/D counts and exported after recording to any post analysis package format for data analysis. Data reduction is available by decimation either during export or during recording which effectively allows the user to change their sample rate on the fly.”

They added, “Export features also allow for the user to export all or certain channels or specific time slices of data. Playback mode allows for recorded data to be replayed and viewed in desired time increments and in many different types of displays. Calculated channels are also easily defined pre- or post-recording and easily displayed and exported along analog data.”

Keithley Instruments focuses on precision data acquisition when accuracy and reliability are a priority, according to Brad Odhner, technical marketingmanager. “Our two main offerings are the DAQ6510 6-1/2-digit data-acquisition and logging multimeter and the 3706A systems switch/multimeter,” he said. “The DAQ6510 features a touchscreen user interface that greatly simplifies test setup without the need to navigate complex menus or use an external computer. It also allows simple real-time monitoring of tests via the frontpanel, allowing users to check their tests at a glance. The 3706A offers a 7-1/2-digit multimeter for enhanced precision and six customizable card slots, allowing test flexibility and up to 576 2-wire channels. Both instruments also offer built-in scripting support with Keithley Test Script Processor (TSP), allowing custom programs and calculations to be run on the DAQs themselves.”

Odhner added that Keithley Test Script Processor (TSP) technology helps to enhance scan speeds and achieve the faster scan rates. “This embedded scripting also allows our DAQs to operate on their own without waiting for a controlling computer to command the next step in a sequence or calculate a result,” he said. “TSP is commonly used so a Keithley DAQ can control a part handler or environmental chamber.”

William Wadkins, FPGA product manager at Digilent, outlined his company’s DAQ products. “We recently released several new products as part of our Eclypse platform: the Eclypse Z7 development board, Zmod ADC, and Zmod DAC,” he said. “The Zmod ADC and DAC can acquire and generate, respectively, signals at up to 100 MS/s with 14 bits of resolution. The Eclypse Z7 also comes with Petalinux supported out of the box, and pre-built Linux images are accompanied by the API for bulk data transfer. This system allows users to plug in their Zmods of choice and get started prototyping new high-speed measurement systems without directly interfacing with the FPGA until desired.”

The Eclypse Z7 with Zmod converters is designed for high-speed instrumentation, control, and measurement. “The best-in-class for performance-per-watt Zynq-7000 SoC also makes this development board suitable for edge-computing,” Wadkins said.

Newark offers DAQ products from a variety of manufacturers. “One of Newark’s best-selling DAQ products is the Keithley DAQ6510,” said Maureen Lipps, product manager, Test & Tools. “This precision data-acquisition/data-logging system features the measurements, functions and traceability of a 6.5-digit DMM plus 80 channels of instrument-grade switching. A large 5-in. multitouch display guides users through set-up, data visualization, and analysis, removing the necessity of a PC and custom software for many applications.” She added that the system is commonly applied to device characterization, where a DUT resides in an environmental chamber and is being stressed under varying environmental conditions. For users who prefer a PC, IVI and LabVIEW drivers are available.

“The B&K Precision DAS220-BAT, another key product in Newark’s DAQ portfolio, measures and records parameters commonly found in process applications including voltage, temperature, current, resistance, frequency, and pulse,” Lipps said. “It includes 10 universal integrated analog channels with convenient screw input terminals. For maximum ease of use, measurement results are viewed graphically and numerically on a 10-inch color touchscreen and saved either to internal memory or external USB memory. The user experience is further simplified and improved through icon-driven menus which make the instrument easy to navigate. The free DasLab Windows PC software allows users to remotely control and configure the recorder, transfer logging results and configuration files, and view live data in graphical or numerical format on the PC.”

“Newark’s broad product portfolio and holistic support services ensure engineers at every level are supported, whether that be to set up simple or advanced acquisitions, or to record, view and analyze data, products such as the TC-08 ensure engineers can do so quickly and easily,” Lipps said.

To 5 GB/s and beyond

According to Oliver Rovini, CTO of Spectrum Instrumentation, the company offers 130 different DAQ products with speeds ranging from 1 kS/s to 5 GS/s. “They are available as PCIe and PXIe cards with one to eight channels on a single card or one to 128 channels in a PC-system,” he said. “For customers wanting a fast setup and a mobile solution, we offer stand-alone units with LXI/Ethernet connection to any PC, laptop, or LAN. They cover the same wide speed range with two to 48 channels per box.” In addition, he said the company offers a 5-year warranty plus support directly from the company’s design engineers.

Rovini also said the company offers easy-to-use and out-of-the-box SBench 6 software for data collection, storage, analysis, and reporting. “The software is designed by Spectrum and focuses on our own product range and supports all hardware features,” he said. “Key benefits are the fast start with first measurement results within minutes and the possibility to do high-speed data streaming with a speed of several GB/s.”

Pentek also offers its Navigator development tools for software and FPGA development, including acquisition and waveform generation engines for triggered operation suitable for radar range gates and beamforming. “We include hardware and FPGA-based decimation and interpolation filters to cover bandwidths from a few kHz to 2.5 GHz,” he said. “Our Navigator Signal Viewer displays time and frequency display of live signals acquired during runtime to speed development of new applications.”

“Per Vices offers the highest bandwidth DAQ products available,” said Brandon Malatest, COO. “Our Cyan platform is the latest and highest performance COTS platform available with up to 16 GHz of instantaneous RF bandwidth and 4x40-Gb/s QSFP+ ports for data transfer to host systems.”

Malatest said the company’s focus is on two parts: data acquisition and data processing. With respect to the former, he said, “Our platforms are very high-performance and application-agnostic, which allow them to meet the needs of many markets. These systems are designed for flexibility for the customer to use as needed.” As for data processing, he said, “Cyan has a Stratix 10 FPGA SoC on board which enables customers to take advantage of very high DSP capabilities on the same platform as the raw data acquisition. These DSP capabilities are either offered to the customer to implement their own solution, or we can use and modify our existing IP to offer a complete solution.”

Targeting niches for DAQ technology

While many DAQ providers address a variety of industries and signal types, others focus on a specific niche. TotalTemp, for example, applies data-acquisition“Lawson Labs has been making high-resolution data-acquisition systems since 1981,” said Thomas Lawson, founder and president. “Distinguishing features include 24-bit resolution, optical isolation, true differential protected inputs, signed USB drivers, and free software with free updates.”

Continued Lawson, “We serve the most demanding lower speed applications. Those include electrochemistry,chromatography, precision temperature measurement, instrumentation, and mechanicaltesting. DC accuracy, stability, flexibility, reliability, and low cost make our productsattractive for both researchWhen asked about tools for data analysis, Lawson said, “A data-acquisition system based on Excel already has first-rate analysis and presentation tools that the customer already knows how to use. We have templates for various applications, and the customer can write their own, if they prefer. Control rules can be as simple or complex as desired, and exceptions or variations or calibrations can be inserted by non-programmers.”

Lawson continued, “If you look at DAQ2GO you will see a company that sells user-friendly spreadsheet templates for many different applications. Their software, with our hardware, makes a first-rate GC instrument, or a viscometer, or an autosampler, or a mechanical testing system.”

Ikonix offers data-acquisition products serving the field of electrical safety test. “The reality is that electrical safety testing is required for compliance,” said Nick Piotrowski, Ikonix USA Product Manager. “Records need to be strictly stored and monitored for analysis and audit purposes, and our solutions meet that customer expectation. Our DAQ solutions cover every customer application. Whether the customer is running a handful of benchtop tests for R&D or compliance purposes all the way up to thousands of safety tests per day—our instruments and software will record and store all data.”

Piotrowski said that in mid-2020, Ikonix USA will release a new SaaS. “This will allow for complete cloud storage of instrument information, test sequences, and test data,” he said, adding that data can be recorded anytime, anywhere without the risk of losing any information. “Ikonix will be the first electrical safety testing manufacturer to offer a SaaS platform for customer data and analytics,” he said.

Software toolboxes for DAQ

MathWorks addresses data acquisition with its software tools. “MATLAB is our platform for data acquisition and analysis,” said Eric Wetjen, senior product marketing manager, test and measurement solutions. “With MATLAB and add-on toolboxes like Data Acquisition Toolbox, Signal Processing Toolbox, and Statistics and Machine Learning Toolbox, our customers can collect and analyze all their data from the same environment.” He said the company offers additional toolboxes for acquiring data from webcams and frame grabbers for computer-vision applications and from software defined radios (SDR) for wireless and RF algorithm development.

“Data Acquisition Toolbox lets users bring data directly into MATLAB from USB, PCI, PCI Express, PXI, and PXI Express DAQ devices from National Instruments and other vendors,” Wetjen said. “For less demanding applications, we have hardware support packages that let user collect data from Arduino and Raspberry Pi directly into MATLAB. MATLAB users can then leverage built-in apps to configure and run a data acquisition session without writing MATLAB code. To later set up automated procedures, users can automatically generate MATLAB code from these built-in apps. Using apps and command-line functions, users can easily control the analog input, analog output, counter/timer, and digital I/O subsystems of their DAQ devices.”

He explained that once the data is in MATLAB, customers can use MATLAB and analysis add-on toolboxes to analyze and visualize data for a variety of signal-processing and AI applications. “For example, our customers often use Signal Processing Toolbox functions and its Signal Analyzer app to explore and preprocess signals. This app can be used to apply low-pass, high-pass, bandpass, or band-stop filters to a signal, and it can remove trends and compute signal envelopes. With the functions and apps provided by Statistics and Machine Learning Toolbox and Deep Learning Toolbox, our customers build and train predictive models for AI and predictive-maintenance applications. These toolboxes provide algorithms for feature extraction, classification and regression algorithms for supervised machine learning, and clustering algorithms for unsupervised machine learning.”

Applications, challenges, and trends

The topics covered in this article span the gamut of DAQ products: simulation and data-analysis software, rugged and portable data recorders, modular instruments, and high-channel-count systems. Vendors will continue to leverage advances in data-converter and communications technologies to meet the challenges of future DAQ applications.

Several contributors to this report elaborated on applications, trends, and challenges in the DAQ marketplace. For example, Pederson at B&K Precision said, “Our data-acquisition solutions feature fast sampling rates of up to 1 MS/s, wide input voltages from a few millivolts to 1,000 V, up to 16 bits of resolution, and battery life up to 15 hrs. This makes our instruments suitable for a wide range of applications from small sensor signal logging to large electrical power analysis in both portable and benchtop environments.”

Pederson added, “The biggest challenge is staying on the leading edge of DAQ technology by providing more channels, better accuracy, and a lower price. We've met this challenge head-on with new platforms and by adapting our user interface to keep up with an ever evolving market and changing customer requirements.

He cited the DAS30/50/60 Series input voltage up to 500 V, fast sampling rate to 1 MS/s, resolution of 16 bits, and the integrated power analysis feature. He also cited the DAS1700’s interchangeable measurement boards, which lets customers configure the recorder to meet their requirements. “These boards allow for up to 72 input channels, a maximum input voltage of 1000 V, and the 1 MS/s on up to six channels simultaneously,” he said. “For applications that require a higher number of input channels, our DAS240-BAT can be configured with up to 200 analog inputs.”

Applications

Ang at Keysight said the company’s DAQ systems are used across multiple industries for product characterization and validation, product manufacturing testing, and process monitoring. Until recently, he said, Keysight standalone DAQ systems were used as data-logging systems capturing static data. However, he added, Keysight’s recently introduced DAQM909A four-channel simultaneous digitizer module for use in the DAQ970 Series enables new dynamic data acquisition applications such as mechanical vibration analysis, acoustic analysis, and dynamic AC/DC power analysis.

When asked about trends, Ang said, “With the proliferation of IoT solutions across all industries, we have seen requirements for new solution form factors, improved connectivity to the cloud for data storage and analysis, improved battery-analysis tools, and lower cost RF measurement solutions.” He also cited a trend toward including data acquisition into simulation models to improve model performance.

Iversen, Burrows, and Bassett said NI’s DAQ portfolio addresses applications ranging from low-channel-count systems for quick measurements to high-density, distributed, and custom systems. “Because our hardware is modular, users can tailor their setup to meet their needs across different applications,” they said. “FlexLogger software provides the sensor configuration, logging options, and event response needed for typical measurements, while LabVIEW can provide lower-level control over an application when custom functionality is necessary. Our NI-DAQmx driver also provides support for third-party languages such as C#.NET, Python, and MathWorks MATLAB software, with its Data Acquisition Toolbox.”

Iversen, Burrows, and Bassett also identified trends that align with connected devices and the IIoT. “There is a need for Ethernet devices that can be distributed and synchronized with minimal efforts, like our time sensitive networking (TSN) CompactDAQ chassis and FieldDAQs,” they said. “Users are also looking for ease-of-use so they can connect their hardware, test their sensor input, configure their measurements, and log and analyze data. FlexLogger application software delivers on that experience and provides the ability to perform engineering analysis with just a few clicks.”

Ross Smith at RADX elaborated on his company’s product offering. “RADX LibertyGT DAQ Solutions uniquely employ COTS hardware and RADX MSFS, with a focus on advanced, wideband, multichannel, synchronized DAQ applications for customers that desire to use their instrumentation as opposed to develop applications for it,” he said. “RADX LibertyGT DAQ solutions are uniquely scalable, high-performance, and low-cost and support precision synchronization that is essential for advanced sensor-based systems.”

Trevor Smith at Pico Technology said the company’s dataloggers are widely used in laboratories and in field applications. “They address diverse engineering, scientific, and industrial applications,” he said. “Up to 20 loggers of any type can be configured and controlled with PicoLog 6 to collect up to 160 channels of data. One or more loggers can be reconfigured in just a few minutes to address the specific measurements that are needed at each stage of a project, or to build ad hoc configurations as the need arises.”

IoT devices are presenting designers with challenges related to conserving power and prolonging battery life, Smith said. “Engineers need more insight about the power consumption behavior of their devices over time and operational life cycles,” he explained. “The Pico ADC-20 / ADC-24 precision voltage loggers provide 20- and 24-bit resolution respectively. Matched with a user-configurable terminal board and precision shunt resistors, the loggers can make differential or single-ended measurements at the µV or µA level with better than 0.1% accuracy.”

In addition, he said, engineers working on embedded systems have to pay special attention to power consumption and thermal performance of their designs to maintain semiconductors and other devices within their specified temperature ranges. “Thermocouple based loggers, such as the Pico TC-08, provide precise multi-point measurements of package temperatures as well as monitoring heat sink, inlet and outlet temperatures, etc. Prototype devices can be equipped with multiple thermocouples to measure all the critical points of a design. Thermocouple loggers are particularly well suited for making multi-channel measurements in an environmental chamber during burn-in or accelerated life cycle testing.”

Smith said scientists and engineers need to make diverse measurements in applications ranging from life sciences through industrial processes. “No one data-acquisition equipment manufacturer can address all of those needs with ‘out of the box’ solutions,” he said. “In addition to PicoLog 6, Pico provides a software development kit (SDK) that enables engineers to write their own applications in the language and operating system of their choice. The SDK includes instrument drivers for Windows, Linux, and macOS; a programmer’s guide; and code examples that shows how to interface to third-party software packages such as Microsoft Excel, National Instruments LabVIEW, and MathWorks MATLAB and programming languages like C, C#, C++, and VB.NET.”

According to Gibson at VTI Instruments, “VTI data-acquisition systems are used by military/aerospace, commercial aviation, automotive, and energy corporations for jet-engine testing, environmental testing, highly accelerated life testing (HALT),and highly accelerated stress screening (HASS). The systems perform vibration testing, acoustic testing, and mechanical stress testing. The breadth of VTI product lines enables them to serve a wide range of applications. The ruggedized line of instrumentation allows testing in the same environment with the devices-under-test (DUTs) to minimize lengths of wiring between the instrument and DUT. This saves on setup time and reduces wiring errors. Employing the TEDS standard for measuring strain gauges can also save substantial setup time when working with a large number of channels. VTI products have helped an aircraft manufacturer reduce test setup time from three weeks to a few days by avoiding confusion and errors with sensor setup and calibration.”

Gibson added, “The interoperability of VTI PXIe and LXI platforms gives users the maximum flexibility to design an optimum system for their application. Instruments that have PoE allow portable testing for vehicle testing applications.”

Asked about trends, Gibson said, “Internet of things technology is impacting the data acquisition world with the incorporation of distributed data services (DDS) and more distributed measurements with smaller and lighter instruments. Small instrumentation permits locating them closer to the DUT to reduce noise and improve signal integrity. That also requires more robust instrumentation. Providing testing capability for advanced flexibility results in more implementation of Ethernet protocols. Test systems often benefit from lower latency and better determinism for control and other data acquisition applications.”

Rovini at Spectrum described the company’s DAQ solutions as general-purpose high-performance products. “They are not designed for a specific application but can be used for any application with signals in the range of a few kHz up to GHz,” he said. “The versatile DAQ systems offer a lot of features like synchronous digital channels, AWG channels, multiple trigger and clock modes, and a wide software support. The DAQ products fit well for applications in the area of NDT, ultrasound, laser, quantum research, medical devices, power discharge, vibration and acoustics and many more.”

Rovini identified trends toward more ADC resolution and more features like mixed-mode operation or the combination on DAQ and AWG technology. In addition, he said, “Lately customers are asking for processing power to have calculations on-the-fly even when acquiring data with 10 or 100 MS/s on several channels in parallel. Spectrum’s easy-to-use approach here is the usage of standard GPUs for highly parallelized data processing.”

Chittey and Rule of VPG said the company supports DAQ applications in full-scale aerospace and space-structural, rocket-engine, wind-tunnel, and explosive testing environments. “Pacific Instruments offers the unique ability to input any type and number of sensors and allows for each input to be set up independently (that is, sample rate, gain, filter, excitation, etc.) of one another,” they said. “Systems are available from 1 to 8,192 channels and can sample at up to 10 MS/s per channel along with digital I/O for real-time control along with a powerful turnkey software package, making Pacific Instruments an attractive solution for a wide variety of testing applications.”

They added that in many test environments and especially full-scale aircraft structural testing applications, customers want to incorporate multiple technologies and data streams into one software package for display, broadcast, and recording purposes. “Pacific Instruments’ turnkey PI660 software allows for load control systems (LCS), fiber optic strain (FOS) systems and digital image correlation (DIC) systems to all be streamed, displayed in real-time, and recorded in parallel with analog channel data,” they said. “Integration of multiple data sources, each with their own unique set of capabilities, into one system allows for easier management of large amounts of data as well as a broader and more useful dataset for analysis.”

They also pointed out that smaller channel-count applications typically require a more portable solution, while larger channel count tests typically have more demanding hardware and software needs that require customization. “Micro-Measurements offers out-of-the-box functionality, whereas Pacific Instruments offers a high level of customization in both its hardware and turnkey software solutions, allowing for a system that is catered to each customer’s specific application and requirements,” they concluded.

Hosking said Pentek’s multichannel DAQ front ends and FPGA engines cover advanced real-time, wideband DSP operations. Application functions include radar, recording, communications, SIGINT, beamforming, phased arrays, electronic warfare, and countermeasures. “Air- and conduction-cooled options cover deployed environments including manned and unmanned vehicles (air, sea, and land), avionics, LEO satellites, antenna electronics, ground stations, and research laboratories,” he said. “We offer a powerful combination of DAQ resources, excellent signal integrity, software and FPGA tools, and lifetime technical support.”

Hosking commented on a trend with respect to RF DAQ applications. “Customers want to perform ADC and DAC operations as close to the antenna as possible to reduce signal degradation from analog RF cables, minimize latency, and slash SWaP in general,.” he said, addinged that they also want to connect DAQ functions using gigabit serial links, typically over optical cables and standard protocols like 10, 40, and 100 GbE.

Malatest at Per Vices said the company’s DAQ solutions serve spectrum monitoring and other applications that require ultrawide bandwidths. “Whereas other solutions offer narrower bandwidths and boast about fast tuning and settling times, our platform allows users to monitor an entire 16 GHz of spectrum at the same time which results in a probability of intercept of 100% within that spectrum,” he said.

“Data-acquisition systems have been improving as the underlying semiconductor technologies have continued to advance,” Malatest added. “This has enabled DAQ systems to sustain higher rates (on both the acquisition and transfer to other systems for processing), a greater number of channels, and extended use cases.” He cited four key characteristics customers look for: “Greater bandwidth capabilities for initial data capture, larger channel count to enable capture of different information concurrently, higher throughput as it related to data backhaul links, and the ability for DAQ systems to incorporate data processing capabilities.”

Wetjen at MathWorks commented that the company’s DAQ tools find use in industry for research and product design validation. “Customers also use MATLAB to automate their testing tasks,” he said, explaining that many data-acquisition tasks require a user interface. “Using the App Designer tool in MATLAB, customers can easily build custom apps for test setups,” he said. “In addition, the built-in apps that are delivered with MathWorks toolboxes allow our customers to collect and analyze test data without writing code…. These features coupled with the breadth of analysis and visualization methods available with MATLAB and toolboxes make our solutions suitable for a wide range of customer applications across industries like automotive, aerospace and defense, semiconductor, industrial automation and medical devices. In academia, our DAQ solutions are also used to teach programming and engineering concepts to freshmen through hands-on experience with test and measurement instrumentation.”

When asked about trends, Wetjen said, “Over the last few years, we’ve seen more customers working with wireless DAQ systems, driven by retrofitting data collection systems for Industrial IoT applications. These wireless sensors are used to supplement existing data that is already being collected.”

He added that MathWorks has also observed that customers need to work with an increasing variety and volume of data. “For both research and test stages, our customers work with signals, images, and radar/RF data,” he said. In many cases, they need access at the same time to multiple types of data such as signals, images, spectra, and textual information. Because MATLAB provides access to a wide variety of data, they can do this easily. In some cases, our customers are trying to access data sets that are too big to fit into memory. For such applications, MATLAB offers a datastore, which enables users to work with large data sets in small blocks that individually fit in memory. When a datastore is used with MATLAB tall table and tall timetable datatypes, the dataset can be analyzed in the same way as a dataset that fits into memory.”

Wetjen added, “In academia, we’ve seen broad use of low-cost data acquisition devices like Arduino and Raspberry Pi for project-based learning and simple data-acquisition experiments. We’ve even seen these devices used for some commercial research applications. However, our customers continue to invest in high-end DAQ equipment for demanding data acquisition projects, and for product validation and production test setups.”

Anderson at MCC also commented on Raspberry Pi, “MCC’s biggest challenge has been to align our business with the fast growth in low-cost Linux and Python computing,” he said. “We have invested significant resources supporting these platforms through open-source Linux drivers for all of our USB and ethernet devices, full Python programming support, and a robust collection of Raspberry Pi DAQ HATS.”

Trends

Odhner at Keithley identified a trend toward leveraging faster scanning speeds to capture more granular details across multiple points of interest at the device under test. “We have been addressing these needs many years, first with reed-relay multiplexer modules, then followed by solid-state relay multiplexer modules,” he said. “The latest update to our DAQ6510 allows our entry-level tools to scan at a rate in excess of up to 800 channels per second using the solid-state multiplexer option. Our larger, more advanced 3706A data acquisition unit can achieve scan rates up to 1,600 channels per second using its solid-state multiplexer option.”

Odhner also discussed some trends. “We see people wanting more options to view and analyze their data,” he said. “On our DAQ6510 system, we address this demand with a richer, more robust graphical user interface for viewing data in a graph, histogram, or traditional tabular format. In addition, he said, “We’re seeing more customers shift from the traditional GPIB-connected lab setups to adopt LAN connectivity. This helps to better support distributed data logging, enabling the user to locate the measurement equipment closer to the device under test and the operator further away, which is especially important when it comes to setups deployed in hazardous environments. Placing the equipment nearer the point of test also promotes having shorter cabling/wiring to the device under test.”

Lawson at Lawson Labs commented on challenges. “A common problem is obsolescence. An older computer fails, and a different data-acquisition company's hardware or software is not compatible with new computers,” he said. “Our customers don't have that problem. We don't obsolete our systems. Take the example of an OEM customer with a Windows XP application written by a programmer who has since left the company. We provide a Windows 10 driver and updated dll. As long as the programmer originally used our defined interface, all the customer should need to migrate to Windows 10 is to update the dll. The driver takes care of itself. Plus, the dlls are backward-compatible, so the OEM doesn't need to worry about other customers still using older hardware.”

Wadkins at Digilent commented on challenges and underlying technologies. “When it comes to the Eclypse specifically, we adopted Opal Kelly’s SYZYGY standard,” he said. “SYZYGY is a golden middle ground of size, performance, and cost. It is a smaller form factor than FMC, but provides substantially more throughput than Digilent’s existing Pmods (hence, we named our SYZYGY-compatible modules ‘Zmods’).” He added, “The challenge we face here is continuing to squeeze more speed and performance through such a small connector, but we think our customers will be pleased with the performance we’re already able to offer.”

Lipps at Newark said the company’s broad range of DAQ products serves several application types—including environmental chamber monitoring, component inspection, benchtop testing, process troubleshooting, and temperature profiling. “A key benefit of the Newark DAQ portfolio is that with many of our data acquisition products, users can monitor devices under test remotely, allowing real-time and accurate environmental testing,” she said. “We’re committed to ensuring our customers not only have access to the products they need to perform the tasks required, but can do so with safety and efficiency guaranteed. Newark’s in-house Test experts are always on hand to offer support to customers who need it.”

Lipps continued, “There are several areas driving the data-acquisition market at the moment, but factory automation and smart manufacturing are two of the most significant. In order to gain greater visibility of machines and floor operations, data acquisition is essential for tracking multiple system parameters and monitoring a multitude of data sources while exchanging data in real-time. As we continue to see the rapid expansion of factory automation and smart manufacturing, we can expect to see an equivalent rise in the need for DAQ systems and technology in these fields.”

REFERENCE

1. Nelson, Rick, “Effective test and measurement drives wide-bandgap device applications,” EE-Evaluation Engineering, March 2020, p. 16.