Modular Building Blocks Simplify DAQ Design

In their search for a reliable – yet flexible – DAQ system for in-depth understanding of system behavior, a European transportation manufacturer in the field of trains and railway infrastructure put its trust in Instrumentation Technologies. The task of supplying a condition monitoring system to watch over countless power inverters was nothing short of challenging. Installation conditions are, in this case, quite the opposite of the laboratory where systems are developed, and the rugged environment represents an added difficulty, on top of the technical performance requirements.

In general, rapid industrial development makes facilities and equipment rely more and more on electric signals as a source of power and information, with subsequent issues regarding evaluation, test and compliance. Optimization of these systems, along with predictive maintenance, requires reliable Data Acquisition at increased sampling rates, especially when looking at fast transients in electrical parameters such as voltage spikes and higher harmonic currents.

Measuring these phenomena is a fundamental step in understanding their impact on electrically interconnected equipment. Monitoring mechanical parameters, converted into electrical inputs at increased sampling rates (such as HFIM – High-Frequency Impulse Measurement), can be extremely useful for performance analysis and early detection of anomalies.

Besides their common factor – the need for high-speed DAQ – every application naturally has its own particular demands and requirements. Developing a system from scratch and adapting it to the specifics of the operation brings along the traditional pitfalls. lengthy – and often unpredictable – R&D process and debugging period, reflecting on the overall budget; reduced reliability of newly designed systems; and, last but not least, potential problems with EMC and the related certification, essential for devices with wireless connectivity, operating in noisy electromagnetic environments which potentially can cause or suffer from problems with radio frequency interference.

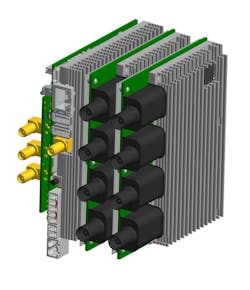

The solution for these main obstacles can be supplied by the modular Building Block data acquisition system, developed by Instrumentation Technologies with proprietary IP. Its robust and validated design provides a series of standardized, tested, and certified bricks to build your house. Each module has a series of individual, isolated inputs, capable of reading a range of different types of analog electric signals and sample them at rates up to 1GS/s at 12 or a maximum of 16 bits. Since the Building Blocks are off-the-shelf products, they are all fully tested and EMC certified, avoiding unforeseen problems during commissioning and operation.

The basic layout of the Building Blocks system consists of a Basic Unit, a DAQ Unit, a Communication Unit (sending data into the system or uploading it onto a cloud server) and a Backplane Unit which connects the individual units. As such, there is no real limit to the number of input signals. For high volumes of input signals, the possibility exists to integrate the Building Blocks into a monolith.

On top of the robust hardware groundworks of the Building Blocks assembly, a second layer is added to provide the customized configuration. This is done, using dedicated or adapted software, and includes settings for sample rates, time- or event-based triggering, post-processing, FFT analysis, alarm signals and time window size, among others. This allows the supply of customized systems, minimizing R&D time and shortening the commissioning and debugging phase, with subsequent cost reduction, as well as shorter delivery times.

The Building Blocks system has been designed to operate in rugged conditions, at operating temperatures ranging from -40° to +85°C, with class IP54 protection, allowing it to work in relative humidity levels up to 95% (non-condensing). Input voltages are a standard 12 Vdc to 36 Vdc range, with a tolerance of -10 to +15%, or 48 V PoE. In case of power failure, the Building Block’s built-in UPS takes over and prevents loss of valuable information.

The number of input signals is virtually unlimited, just a matter of adding more Building Blocks where needed. What the unit does afterwards with the input signal can be entirely adapted, for example using lower frequency-sampling and use the longer time-window to store data in the local GB-range RAM. Where necessary, especially for analysis of electric fast transients, the customer can also select high-frequency sampling, and use the full system capacity up to 1GS/s. In case of the latter, the time window will be drastically reduced, requiring continuous use of one of the interfaces (USB, Ethernet or external antennas) to send the data for external storage, either physical or cloud-based. Easy remote access to the unit is also possible through the same interfaces.

Triggering the sampling when required is another important aspect of DAQ and data size management. This to avoid unnecessarily big data files with irrelevant information, bringing along a waste of processing and analysis time. According to the specific needs, sampling can be triggered on a time basis, but also by events, such as single thresholds or a set of conditions, setting off sampling on the signals of choice. Pre-trigger delays can be separately configured as well.

Needless to say that, without effective post-processing, even the most reliable and completest data set becomes irrelevant. The previously mentioned multiple interfaces are used to send the information to the station where final analysis will be performed, either in real-time or at a later stage. Also here, the use of robust standard software guarantees flexibility and user-friendliness during this task, either via API-level software support, or using a graphical control user interface, based on LabVIEW. This allows in-depth analysis of fast transients, as well as long-term monitoring of slow phenomena to enhance predictive failure recognition.

Addressing Applications

In general, in all areas where critical operational data needs to be recorded in a fast and reliable way, Building Blocks can be used to build a system according to specific customer needs. Besides the previously mentioned railway infrastructure example, other example cases where the Building Block technology has been used are include a prominent space agency, addressing its need for a ruggedized DAQ device to monitor atmosphere parameters within space modules, and the ITRON Smart City Challenge in London, where a project was set up to enhance safety along the river Thames. Instrumentation Technology´s development is used to connect and track safety equipment, detect possible river entries and accelerate response time for emergency services.