NI Taps Modular Hardware to Help Scale Up Production Testing

Check out our NI Connect 2022 coverage.

For years, NI has focused on the ability of software to tie together its test equipment and evaluate vast quantities of data to help companies reduce their time to market and build better products.

But at its annual NI Connect event, NI also introduced a new hardware offering called TestScale for testing the circuit boards at the heart of consumer, medical, and other high-volume electronic devices.

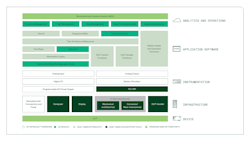

TestScale is based on modular, off-the-shelf hardware. NI said customers can slot digital and analog I/O and power-supply modules into a backplane that connects via USB to a PC running application software to test PCBs before departing the factory. NI said the modules can be arranged in custom configurations to meet different functional testing needs. The company plans to add other instrument modules down the road.

NI said that TestScale fills a gap in its product portfolio for test engineers and system integrators. TestScale fits in where NI's PXI-based high-performance automated test equipment is over the top for the task at hand.

Every PCB design is put through rigorous testing and validation during the production process to make sure the complete system and all of the components on it don't have faults that could adversely affect a product’s performance out in the field. One of the final steps in manufacturing a circuit board is functional testing, which is used to check the functionality of the final product and its compliance with the specifications.

In functional testing, the circuit board is subjected to a series of electrical signals and power supplies that simulate the operating conditions. Depending on the complexity of the PCB—and customer demands—these tests may involve simply checking whether the product can be turned on or not—or diving deep into whether it is functionally safe and secure.

In many cases, companies have to run the full range of tests required for the finished circuit board—called “test coverage”—with huge stacks of high-end test equipment that resemble the server racks in a data center.

But NI said TestScale would give its customers the ability to distribute the functional testing over several different stages to keep costs in check, with each station testing a different aspect of the board’s design.

According to NI, this is ideal for testing circuit boards in medical, industrial, and consumer electronics as well as other devices that are manufactured in huge quantities—or those that have several circuit boards under the hood.

With its smaller footprint, NI said TestScale is also very flexible, allowing its customers to swap the test modules in and out more rapidly and replicate test systems to scale up production more affordably.

The small form factor also allows the TestScale hardware to be mounted inside the test system, placing it directly under the device being tested, saving valuable space on the factory floor. Mounting the test system as close to the PCB as possible creates shorter signal paths to help simplify wiring in the system. NI said that also reduces failure points, with better quality and reliability versus custom board-level hardware.

The in-fixture architecture, according to NI, reduces footprint of the final test system by up to 50%. It also promises to reduce the test station cost by up to 40% compared to standard rack-based box instruments.

The hardware connects to NI and third-party software such as TestStand, LabVIEW, and Python using the company’s NI-DAQmx library. It also supports a broad range of Linux distributions for desktop PCs.

Check out our NI Connect 2022 coverage.