This file type includes high resolution graphics and schematics when applicable.

Some of you may remember the classic musical from the 1960s and ‘70s titled “It’s a Bird...It’s a Plane…It’s Superman!” As the title suggests, it’s difficult to definitively categorize a flying object merely by observing it at a distance. In fact, this is particularly true when objects such as birds, airplanes, and superheroes are similar in both form and function.

Twenty years ago, a similar line might have been: “It’s a spectrum analyzer…It’s a software-defined radio (SDR)…It’s a PXI system!” Back then, such a line would have been accurate. Even at a distance, spectrum analyzers were clearly distinct from SDRs—and PXI was still as mythical as Superman. Today, however, each of these “instruments” are often virtually indistinguishable, since a PXI system can double as both an SDR and a spectrum analyzer.

The growing software capability of PXI instrumentation has blurred these once clear distinctions. More specifically, the ability for engineers to deploy intense signal-processing algorithms on PXI systems is allowing for the use of PXI in an ever-expanding range of applications—including those that we might classify as SDR.

As a result, engineers not only use PXI to replace their traditional spectrum analyzer; leading researchers use PXI to prototype advanced electronic systems ranging from passive radars to 5G test beds. In many of these applications, the requirements for high-performance transceivers combined with the need for intense signal-processing algorithms have ultimately led engineers to use FPGA technology in PXI.

Using FPGAs for Signal Processing

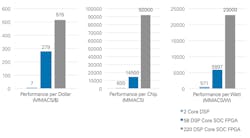

One of the unique characteristics of FPGAs is the ability to execute computationally intense and increasingly parallel signal-processing algorithms in real-time. In fact, today’s FPGA technology can deliver higher computational performance, and at lower cost, than digital signal processors (DSPs). Thus, FPGAs—often augmented with graphical programming units (GPUs)—have become a central element of advanced system design applications.

For example, in Figure 1, observe the difference in performance between state-of-the-art DSPs and FPGAs. According to the figure, FPGAs significantly outperform DSPs in terms of millions of multiple-accumulate operations (MMACs) per second. In addition, the FPGA holds the advantage both in MMACs per dollar, per chip, and per Watt of power.

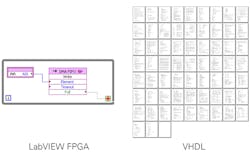

Along with the advances in computational power, a second key advance in FPGA technology is the development of high-level synthesis (HLS) software. Historically, most engineers programmed FPGAs using traditional text-based methods, such as Verilog or VHDL. With either of these languages, developing computationally intensive signal-processing algorithms is relatively cumbersome—and requires detailed knowledge of the programming language. In addition, many applications require integration of hardware I/O, adding more complexity to the FPGA software.

One of the new frontiers in instrumentation is the ability for high-level abstraction software to not only synthesize FPGA IP, but also simplify the integration of the IP with hardware I/O. As an example, Figure 2 compares the required code to acquire a single analog data sample from an ADC and then write that sample to a direct-memory-access (DMA) FIFO. As the figure illustrates, the code on the left, which uses LabVIEW FPGA, is substantially simpler than the VHDL code on the right.

By solving these challenges, our industry is enabling engineers to use instrumentation platforms in a much wider range of applications. For many engineers, the ability to execute custom, advanced signal-processing algorithms on the FPGA of an instrument eliminates the need for them to design additional hardware.

Passive Radar

One such application that benefits from a user-programmable FPGA in PXI is passive radar research (Fig. 3). For example, Selex System Integrati in Rome, Italy uses NI’s LabVIEW FPGA software to develop advanced passive radar systems. Passive radar is a unique application because unlike traditional radars, which use an onboard “illuminator” to generate a stimulus signal, passive radars rely on environmental illuminators such as cell towers, satellite transmissions, and broadcast stations. The principle purpose of passive radar is to measure a signal’s direction of arrival by carefully separating the incident signal from the reflection.

Prototyping a passive radar system introduces technical challenges both in the hardware and software implementations. On the hardware side, passive radar systems require tight phase synchronization between large numbers of receiver channels along with high-throughput data movement to a central processing unit. Due to these requirements, modular instrumentation platforms such as PXI are an ideal solution. That’s because PXI is inherently designed to handle both the synchronization and throughput requirements.

In addition to hardware, applications like passive radar also require intense signal processing, and typical algorithms include filtering and cross-correlation between multiple channels. Given the massive parallelism and sophistication of the required signal processing, FPGAs are a critical technology. For the team at Selex, the path to using FPGAs involved NI’s LabVIEW FPGA tools to develop their own passive radar IP and deploy PXI systems as a passive radar in the field.

Conclusion

If your idea of an RF signal analyzer is a screen that merely illustrates a spectrum display, then your expectations of instrumentation are too small. With evolving instrument platforms such as PXI and software that makes the instrument’s FPGA accessible to program, today’s instruments are experiencing a dramatic increase in their capabilities. Next time you think about designing your own hardware to solve a signal-processing challenge , consider using an instrument. You might be surprised at what it can do.