This file type includes high-resolution graphics and schematics when applicable.

Engineers often have a strange nostalgic affinity for their instruments. Seasoned RF engineers who have worked in the field for many years frequently refer to their traditional instruments as “toys” and talk about them like my grandfather used to talk about his old Jaguar sports sedan. However, like my grandfather’s old Jaguar, the traditional instrument as we know it will soon be nothing more than an engineering relic.

A revolution in measurement technology is driving the replacement of traditional instruments with test systems. A decade ago, the interface to an RF signal analyzer was a physical knob or button. Today, that interface is a mouse click or an instrument driver call in software.

Escalating Device Complexity

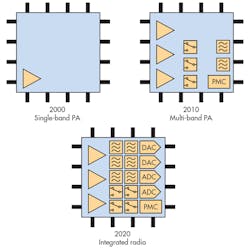

Consider, for example, the RF power amplifier (PA). In 2000, a PA was a 4-pin device with connectors for RF input, RF output, dc power, and ground. Today, it’s a multimode device with a digital interface and nearly two dozen RF ports. Within the next five years, the PA will become a complete radio with integrated baseband and power management (Fig. 1). In addition, use of advanced technologies like digital predistortion (DPD) and envelope tracking make testing even more complex.

As a result, an engineer cannot turn on today’s complex PAs merely by pushing knobs or buttons on an instrument. Instead, just powering up the amplifier—even to make a basic power measurement—requires a sophisticated choreography of multiple instruments that are automated with software.

Once a simple device, the modern RF PA represents an industry-wide shift in the escalating complexity of ICs and consumer electronics. Some of the most mundane parts, such as a power-management IC (PMIC), are often integrated into more complex systems that include microcontrollers and other sensors. As the complexity of these devices evolves, the equipment and methods used to test them must evolve as well.

Instrumentation of the Future

Two decades ago, test vendors would often design an instrument even for one specific measurement—and at the time, this approach was completely appropriate. The ability of a spectrum analyzer to measure third-order intercept or phase noise with a single button push was an innovation.

By contrast, testing a modern RF front end requires the instrument to implement the DPD functionality in software. Testing a radar transponder requires the instrument to emulate the radar environment. Finally, testing a digital-to-analog converter (DAC) or analog-to-digital converter (ADC) requires careful coordination of analog and digital interfaces. Due to these changes, test instruments have grown obsolete, and test systems uniquely suited to the particular device they’re testing are replacing these instruments.

Today, the biggest innovations in instrumentation technology allow once-separate instruments to work better together. Even in the traditional box instrument world, the latest instrument software is designed to automate multiple instruments. For example, some signal analyzers can work as signal generators, power meters, or even oscilloscopes through a digital interface. In addition, test vendors are increasingly offering what they refer to as reference applications, which include GUI software to control multiple instruments in order to address a specialized test need. However, the practice of gluing together traditional instruments often results in a slower, more expensive system with worse synchronization than provided by modular instrumentation.

Consequently, the transition from an industry of test instruments to test systems has fueled the growth of modular test platforms such as PXI. PXI instruments can be synchronized, sequenced, and controlled with software. Many engineers ultimately choose the PXI platform because they can use it to create unique, custom instruments that are ideal for their particular applications.

Market Shift from Traditional to Modular

Not surprisingly, the market demand for test systems is driving the adoption of modular test platforms like PXI. Consider the revenue history and forecast of the test-equipment market (Fig. 2). The PXI revenue forecast is based on the 2016 Frost & Sullivan PXI market report. Market size for traditional instruments is derived from the assumption that the test and measurement market will remain flat from 2016 through 2021, and represents a somewhat aggressive forecast given that the last four years produced negative growth in test-equipment revenue.

This forecast also reveals that the overall market for traditional instruments is actually shrinking. Within the next five years, the market for traditional instruments will shrink by around 25%. And by 2021, PXI instruments will represent nearly 40% of the overall test and measurement market. Although the market will always have use cases for traditional instruments, this data illustrates a remarkable trend that’s changing the dynamics of the market.

The Importance of an Ecosystem

One significant outcome of this changing dynamic is the increasing importance of an ecosystem. When the measurement result was as simple as the push of a button, engineers relied completely on the instrument vendor to help them make better measurements. However, when producing the measurement result requires the design of a system, engineers require not only more sophistication, but also the support of an ecosystem. Here at National Instruments, we believe that the ecosystem of our community is critical to the success of all engineers. As devices become more complex and measurements more nuanced, the ecosystem is the only way to ensure engineers can be successful.

So the next time you pull the old spectrum analyzer out of the closet, take care of it the same way my grandfather took care of his old Jaguar. It won’t be around forever, and you may want to look back at it at some point to remind you of the good old days.

Looking for parts? Go to SourceESB.