While autonomous vehicles hold sway with the masses, engineers are busy making sure what we have now continues to operate safely, effectively, and in compliance with recognized standards from bodies such as the Society of Automotive Engineers (SAE). That said, technology is changing rapidly and the SAE is going full tilt to keep up. Here is a selection of electronic hardware and software SAE standards, both new and updated, that you should be watching to ensure you don’t get “dieseled.”

1. (SAE) Recommended Practice for Pass-Thru Vehicle Programming (J2534/1)

Last revised in December 2004, the update of the Society of Automotive Engineers (SAE) Recommended Practice for Pass-Thru Vehicle Programming (J2534/1) is particularly interesting given the recent Volkswagen diesel emissions debacle. The RP describes a standardized interface that connects between a PC and vehicle to enable the reprogramming of emission-related control modules. It allows each vehicle manufacturer to control the programming sequence for the electronic control units (ECUs) in their vehicles.

Rationale for 2015-10-2 Update

Concerns from vehicle OEMs, regulators, and application programmers prompted updating of the J2534-1 document to address a wide range of items, from ensuring testability and consistency among compliant devices and clarification of APIs, to message handling, timing/control settings, and the addition of a pass-through device discovery mechanism.

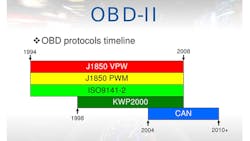

2. Class B Data Communications Network Interface (J1850)

The Class B Data Communications Network Interface (J1850) standard is widely used for diagnostics and data sharing in applications such as engine, transmission, ABS, and instrumentation. Class A supports rates up to 10 Kbit/s, Class B supports rates of up to 100 Kbits/s, and Class C supports up to 1 Mbits/s. The standard defines a minimum set of data communication requirements such that the resulting network is cost-effective for simple applications and flexible enough to use in complex applications.

Rationale for 2015-10-14 Update

Last updated in 2006, J1850 is being revised to detail a High-Speed Mode (83.3 Kbits/s) using pulse-width modulation (PWM), as well as 4x Speed Mode (41.6 Kbits/s) and Block Mode (unlimited data length) for the VPW protocol (popular with GE).

3. SAE Standard J551/15 for Vehicle Electromagnetic Immunity

Nothing spells disaster quite like an electrostatic discharge (ESD) at the wrong time, such as at a gas station, or when an internal electronic module is in use at a critical time. The SAE standard J551/15 for Vehicle Electromagnetic Immunity—Electrostatic Discharge (ESD) specifies the ESD test methods and procedures necessary to evaluate electronic modules intended for use in complete vehicles.

Rationale for 2015-09-17 Update

The document has been finalized based on the conclusion that it contains basic and stable technology that is not dynamic in nature. As such, it is a good starting point for designers of any automotive electronic module.

4. SAE J1962 Diagnostic (OBD) Connector Standard

SAE J1962 details the requirements of an on-board Diagnostic (OBD) Connector as defined by U.S. On-Board Diagnostic regulations. It sets forth the functional requirements of the vehicle connector as well as the external test equipment.

Rationale for 2015-09-11 Update

When the California Air Resources Board (CARB) asks for clarification, it’s time to provide it. In this case, CARB wants clarification regarding the access area to the vehicle diagnostic connector that is intended to provide proper clearance for the mating of the scan-tool connector to the vehicle. The SAE committee has responded in kind and approved the review of J1962.

5. SAE J1939-73 Diagnostics Application Layer

SAE J1939-73 Diagnostics Application Layer defines the SAE J1939 messages to accomplish diagnostic services and identifies the diagnostic connector to be used for the vehicle service tool interface.

Rationale for 2015-08-28 Update

Changes were made to address issues identified during the development and of the SAE J1939-84 test capability. Among others, changes include adding text to limit the number of SPNs that need to be reported in DM24 for data stream, freeze frame, or test results.

6. SAE J2600 Compressed Hydrogen Surface Vehicle Fueling Connection Devices

Hydrogen fuel cells for automotive applications continue to evolve, but it has to do so carefully given the storage pressures involved. SAE J2600 Compressed Hydrogen Surface Vehicle Fueling Connection Devices helps in this evolution by setting the standard for the design and testing of compressed hydrogen surface vehicle (CHSV) fueling connectors, nozzles, and receptacles.

Rationale for 2015-10-21 Update

Only three years after the last revision in 2012, J2600 was revised in October of this year to reflect the incorporation of additional geometries for different pressures, and to modify, add, or delete testing requirements based on lessons learned as the state of the art has progressed. Also, the document moved from a Recommended Practice to Standard.

7. J1939/16 Automatic Baud Rate Detection Process

J1939/16 Automatic Baud Rate Detection Process is a brand-new one from the SAE. It is tasked with defining a process enabling devices to detect the baud rate of a network automatically without disrupting existing devices.

Rationale for its issuance on 2015-10-04

Manufacturers of devices capable of operating on SAE J1939 networks with different baud rates need to reliably detect the baud rate of that network segment—without interrupting network communications. The goal of J1939/16 is to establish a common method of automatically detecting the baud rate of an SAE J1939 network.

8. SAE’s J3029 Forward Collision Warning and Mitigation Vehicle Test Procedure—Truck and Bus

The name itself is a mouthful, but we’re thankful it now exists: the SAE’s J3029 Forward Collision Warning and Mitigation Vehicle Test Procedure—Truck and Bus is also a brand new Recommended Practice to establish a uniform test procedure for forward collision avoidance and mitigation (FCAM) systems used in highway commercial vehicles and coaches greater than 10,000 lb.

Rationale for issuance on 2015-10-22

With widening commercial availability of FCAM systems, a vehicle test procedure to evaluate the effectiveness of these systems is justified. J3029 outlines a basic test procedure to be performed under specified operating and environmental conditions. It does not define tests for all possible operating and environmental conditions. Minimum performance requirements are not addressed in this document.