Experts and novices alike can use a helping hand when making measurements. Many test-and-measurement companies offer software tools with their instruments, helping to speed instrument setup and avoid making errors. Among the highlights, companies including Keysight Technologies, Tektronix, Rigol, and Siglent have all recently introduced or updated tools for their instrument lineup. Such tools enhance general instrument configuration and communication as well as address specific instrument classes—from DMMs to vector network analyzers—and application areas. In addition, Marvin Test Solutions just announced a new release of its flagship software, which combines test-executive functionality with test-program control and automation. Finally, National Instruments recently has made news with regard to both hardware and software.

Indeed, when you think of instrument software and National Instruments, what might come to mind is a LabVIEW-driven automated system having racks of PXI modules. But since 2014, the company has offered a benchtop instrument called VirtualBench, which combines the functionality of multiple instruments, including an oscilloscope, function generator, power supply, DMM, and general-purpose digital I/O.

The instrument has no displays, knobs, or buttons—USB, Ethernet, or Wi-Fi provides connectivity to a Windows-based software application. (An Apple iPad application supports Wi-Fi connectivity.) VirtualBench includes software capabilities like digital phosphor density maps for displaying multiple acquisitions simultaneously, an X-Y mode for plotting channels against one another, and hands-free smart capture for automatic data capture of repeated stable waveforms.

In February, NI upgraded the VirtualBench hardware—the VB-8054 version (Figure 1) includes a four-channel, 500-MHz mixed-signal oscilloscope with a 2-GS/s sampling rate and protocol-analysis capabilities (34 digital channels) as well as a function generator with 40-MHz max sine output plus a 5-MHz output for square, ramp/triangle, DC, and arbitrary modes. On the software side, NI provides free software and firmware updates as new features are released.

Courtesy of National Instruments

“VirtualBench has both an interactive software application as well as APIs for LabVIEW, C, and Python,” said Michael Keane, NI Product marketing engineer for test systems. “This allows the product to uniquely serve engineers who need both light automation and effective, interactive debugging—we have seen this need in both V&V and low-cost production settings. While this need may have been previously served by both automation equipment and traditional benchtop instruments, VirtualBench stands as a single solution for both needs.”1

Connect and measure

BenchVue is Keysight Technologies’ software that lets users connect, make measurements, record results, and achieve results across multiple instruments with no programming; it runs on a PC or mobile device. The latest version, BenchVue 2017, was released in April. BenchVue consists of the BenchVue platform and multiple BenchVue apps that are designed for different instrument types and purposes, according to David Tu, software product manager at Keysight.

“BenchVue software supports 13 different bench instrument classes and five different USB modular instrument classes,” Tu said. “This software is designed to have different apps for each type of instrument class.” For example, he explained, “The BenchVue Digital Multimeter app is a separate app that runs inside of BenchVue and is designed to work with DMMs.” In addition, he said, “We have apps for function generators, power supplies, oscilloscopes, data-acquisition units, power meters/sensors, FieldFox handheld analyzers, universal counters, AC power analyzers, solar array simulators, electronic loads, spectrum analyzers, signal generators, and network analyzers.”

BenchVue software apps include control, analysis, and automation apps as well as application-specific apps. “With all BenchVue apps, measurement data, screen captures, and trace captures that have been collected can easily be exported in a few clicks of the mouse,” Tu said, enabling users to quickly export data to MATLAB, .CSV, Excel, or Word formats. “With the control and analysis apps, users can set up and control their instruments, capture data, and visualize their measurements for analysis right inside of the software,” he said. For example, the BenchVue Power Meter/Sensor app enables multiple views of RF power measurements to help users better understand their modulated data. The BenchVue DAQ app allows users to set up and view multiple channels of data logs on strip charts and visualize calculated data over time.

“With the control and automation apps like our DMM, oscilloscope, or function generator apps, users also can control setups and visualize measurements and waveforms,” Tu said. “However, the key differentiator with our control and automation apps is the capability to use the same interface that you use to control the instrument and create automated tests in minutes,” he said. “With BenchVue Test Flow, included with most apps, no longer do users need to find and code instrument-specific SCPI commands or use drivers.” Instead, they simply drag and drop controls from their app into a Test Flow sequence (Figure 2) to automate tests as easily as if they were using the instrument front panel.

Courtesy of Keysight Technologies

He noted that traditionally users have either had to perform manual testing or develop an automated test to characterize their DUTs. Manual testing works and makes it easy to set up test conditions since users understand their instruments, he said. “But it is laborious, prone to missing critical data, and is suited to smaller characterization needs,” he continued. “Automated tests are preferable for tests that need more repeatability or require a significant number of test points.” The downside is that automated tests typically require hours or weeks to develop and debug. “Not only do you need to learn the programming environment, but you also need to learn the instrument programming language,” he said. “With BenchVue Test Flow and the BenchVue control and automation apps, you can save hours of manual testing time and days to weeks of automation testing.”

From AWGs to VNAs

Tektronix offers several software products for its instruments. David Njuguna, technical marketing manager for Tektronix performance products within the Americas region, explained that the company recently introduced an arbitrary waveform generator, the Model AWG5200, which has a new software platform that allows users to create waveforms as well as have full remote access to one or more instruments from an interface that mimics the company’s AWG70000 arbitrary waveform generator and the AWG5200 itself. “In addition, we added an ever-expanding library of waveform creation plugins that are Windows 7 compatible on the SourceXpress platform,” he said, adding that the plugins address high-speed serial, Wi-Fi, radar, electronic warfare, optical, and network market segments.

“Software plugins can run on either on a Tektronix AWG5200 or AWG70000 or on a PC using SourceXpress depending on what the customers are working on and how they choose to access the device,” he said, adding that the new SourceXpress allows for AWG instrument control and waveform generation capabilities on a Windows PC. “A user can load waveforms, create sequences, and enable playback without ever having to touch the AWG instrument or enter the lab,” he said.

He emphasized that SourceXpress allows the customers to create signals anywhere and not be tied to a signal generator. “Instrument setup and control is achieved using the customer’s Windows PC (64-bit) through a single consistent UI that also provides for multi-instrument control capabilities,” he said. “Waveforms captured by oscilloscopes or real-time spectrum analyzers can be played back, edited, or resampled on the AWG5200 as well.” In addition, waveform vectors can be created or imported from third-party tools such as MATLAB or Excel, thus providing the flexibility for any desired waveform generation. Reports can be generated using standard tools such as Word, Excel, or even MATLAB.

Tektronix offers other tools as well, such as SignalVu-PC, which provides one user interface for RF and vector signal analysis and works with the company’s real-time spectrum analyzers and USB spectrum analyzers. Wilson Lee, technical marketing manager for Tektronix mainstream products within the Americas region, added that in December 2016, Tektronix released Version 1.0.16 of its DataVu-PC analysis software for real-time spectrum analyzers, which will be covered in more detail in next month’s special report on signal and spectrum analyzers.

More recently, Lee said, Tektronix introduced its TTR500 vector network analyzer, which integrates six RF receivers and two RF sources into a proprietary ASIC. As part of this new product, Tektronix offers VectorVu-PC software (Figure 3). Lee said, “VectorVu-PC software provides the intuitive user-interface look-and-performance feel customers have become accustomed to with SignalVu-PC.” Optimized for either touch or mouse control as well as manual or automated operation, VectorVu-PC software enables easy import/export of S-parameter data files among other key features and benefits.

Courtesy of Tektronix

VectorVu-PC will prove useful whether you are designing and validating RF components and systems, fine-tuning RF components on an assembly line, performing final-acceptance testing of devices off the line, or teaching RF theory and system design, he said.

In addition, Lee said, on May 1 the Tektronix Keithley business announced an update to KickStart instrument control software to support additional source-measure units within the KickStart I-V Characterizer Application.

“This application already supports Series 2400 Graphical SourceMeter SMU Instruments, which include Models 2450, 2460, and 2461,” Lee said. KickStart version 1.9.5 adds support for Series 2400 (nongraphical) instruments, Series 2600B systems, and the Model 6430 sub-femtoamp remote SMU Instruments.

“The I-V Characterizer app in KickStart is designed to enable current vs. voltage (I-V) testing of a variety of materials, two-terminal and multiterminal semiconductor devices, solar cells, and much more,” Lee said. “The I-V Characterizer app programs each SMU instrument for a variety of bias and sweep sourcing operations while measuring voltage, current, and resistance.”

Lee added, “This new software follows the November 2016 revision, which added a high-resistivity measurement application as an option for KickStart, designed for use with Keithley’s Model 6517B electrometer/high-resistance meters.” The KickStart High-Resistance Measurement option, he said, has made it easier for material scientists, physicists, and chemists to:

- quickly and reliably determine resistivity of a material using a test setup that conforms to the ASTM D257 and IEC 60093 resistivity standards,

- perform a step response test to identify electrification time appropriate to the material’s time constant, and

- use the Keithley alternating polarity measurement technique to eliminate inherent background currents for the most accurate resistivity measurements.

Instrument-specific lineup

Rigol Technologies offers a variety of free and low-cost software packages, including UltraSigma communication software, which supports all of the company’s instruments for basic communication and screen capture. Individual instrument capabilities are accessed via instrument-specific software, including UltraScope (virtual front-panel operation for Rigol oscilloscopes), UltraSpectrum (spectrum-analyzer remote control and spectrogram waterfall chart functionality), UltraView (measurement setup and recording with Rigol 5.5-digit DMMs), UltraAcquire (setup, scan, and analysis of data from the M300 Series data acquisition systems), UltraStation (arbitrary-waveform creation software), UltraLoad (virtual front panel and application recording for DL3000 electronic loads), UltraPower (virtual front-panel operation for Rigol power supplies), and Ultra IQ Station (IQ waveform creation utility for the DSG3000 Series RF generators with the IQ option).

Chris Armstrong, director of product marketing and software applications, said, “Part of what separates Rigol is our commitment to free or low-cost software interfaces for almost all of our equipment in addition to application-focused software packages that help customers get the most out of their instruments. Recently, we have updated our UltraStation waveform-generation software to work with the DG1022Z.”

Rigol also has added the new UltraLoad software that works with the company’s new line of DL3000 Series electronic loads. “UltraLoad enables customers to record and graph in real time the voltage, current, power, and resistance of the load,” Armstrong said. “It also includes a new virtual front panel for complete remote operation when the load is in a difficult-to-reach test environment. These utilities are built around the UltraSigma communication software that simplifies VISA communication with any Rigol instrument and provides basic communication as well as screen capture and data charting capabilities. The latest software and firmware versions can support remote control of Rigol instruments over RS-232, USB, LXI, and GPIB, depending on the instrument.”

In addition, Armstrong said, “Rigol continues to add application-focused software where additional analysis or capabilities are a benefit to the engineers we work with.” He cited as an example the S1210 EMI software, which recently was updated to enable advanced EMI testing and reporting when using any of the company’s DSA800 Series spectrum analyzers.

Also, he said, “As more engineers need to look at active RF communication to support their latest product development, we have launched the S1220 ASK/FSK demodulation software.” This software enables engineers to reconfigure their 3.2-GHz and up DSA800 analyzers to analyze the data stream encoded on common FSK and ASK protocols such as Z-Wave and NFC (Figure 4).

Courtesy of Rigol Technologies

“On the power side of the design,” Armstrong said, “Rigol’s 2000 and 4000 Series oscilloscopes work with our UltraPower analyzer software to analyze operating area, in-rush current, harmonics, and more as engineers test switching power supply designs.”

Siglent is another company offering software specific to an instrument class, such as EasySpectrum (Figure 5), which works with Siglent’s spectrum analyzers. Jason Chonko, applications marketing manager at Siglent Technologies America, said, “Siglent has recently updated our EasySpectrum software to help improve the data collection and analysis when using the SSA3000X Series spectrum analyzers. The software incorporates a broadcast-monitoring and an EMC precompliance test mode, which are designed to help engineers find problems and verify solutions as quickly as possible without having to write any code. The latest edition includes a new peak search function in the EMI mode that helps isolate failures more quickly.”

Courtesy of Siglent

Chonko added, “EasySpectrum has two distinct modes that ease data collection and control. Monitor mode is ideal for observation and collection of broadcast signals, interference, or transmitter characterization.” He said the software supports full instrument configuration, including tracking-generator programming, marker functions, and automatic measurements.

As for the second mode, he said, “The EMI precompliance mode provides an easy-to-use interface for sequencing electromagnetic compliance scans and a reporting tool that helps you keep your data organized.”

Adding test-executive capabilities

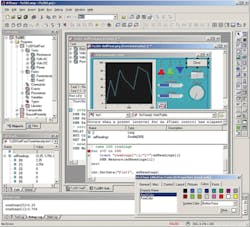

Marvin Test Solutions’ approach to instrument control is ATEasy software, which adds test-executive capabilities for managing overall test program control/automation. Mike Dewey, director of marketing, said the company now is releasing the latest version—ATEasy 10.

ATEasy (Figure 6) has existed for 25 years as a commercial test-executive/test-development software product, Dewey said, noting that ATEasy 10 continues to offer backwards compatibility with previous versions as well as offering new features, capabilities, and higher run-time performance. “Designed specifically for test and measurement applications, its intuitive and structured architecture makes it easy for both novice and experienced test engineers to develop and deploy test programs for both development and production-test environments,” he continued.

Courtesy of Marvin Test Solutions

ATEasy supports all classes of instruments and instrument control interfaces—“All that is required is the corresponding driver,” he said. USB, Ethernet, GPIB, RS-232, VXI, AXIe, LXI, and PXI instruments are all supported.

Dewey explained that ATEasy allows the user to communicate via an instrument’s API or its UI for control and setup. Optionally, users can create their own UI via a custom panel. Further, he said, ATEasy includes a full-featured data-logging capability with data-log files being available in text, MHT, and HTML formats. He concluded, “ATEasy supports comprehensive simulation of the complete test program, allowing the debugging and development of test programs without system or UUT hardware, which accelerates the development and deployment of test programs. ATEasy also interfaces with various commercial code control systems—simplifying overall management and control of test program versions.”

Other companies offering software for their instruments include Spectrum GmbH and Pico Technology. The latter provides, for example, software for the PicoScope 4444 high-resolution differential USB oscilloscope. The company says the software dedicates almost all of the display area to the acquired waveform to allow users to see the maximum amount of data. With the large display area available, users also can create a customizable split-screen display and view multiple channels or different views of the same signal at the same time. The software also can show multiple oscilloscope and spectrum-analyzer traces at once. In addition, each waveform shown works with individual zoom, pan, and filter settings. The PicoScope software can be controlled by mouse, touchscreen, or keyboard shortcuts.

For Spectrum GmbH’s digitizer products, the company offers SBench 6, an easy-to-use graphical user interface. SBench 6 provides control of all the digitizer’s operating modes and settings. The software has a number of built-in features for waveform display, data analysis, and documentation. Acquired and analyzed waveforms can be stored and exported to other devices or other software programs in a number of formats such as MATLAB, ASCII, binary, and wave.

For users who do want to do their own programing, Spectrum’s products come with drivers that allow users to write their own control programs with a variety of popular programming languages, including C++, Visual Basic, VB.NET, C#, J#, Delphi, IVI, Java, and Python. The company also provides third-party software support for LabVIEW, LabWindows, and

MATLAB.

The company’s most recent product offering is an option (M4i.22xx-ir40m) for its high-speed 22xx Series digitizer products that increases their sensitivity and therefore absolute resolution for low-amplitude signals in the ±40-mV up to ±0.5-V range. Products without the option are optimized to acquire, store, and analyze signals in the ±200-mV up to ±2.5-V range.

Other companies are targeting specific applications, such as carrier acceptance test or WLAN validation. For example, Rohde & Schwarz has combined software and hardware to form its new R&S TS-290 IoT carrier acceptance test system, which offers RF, protocol, and performance test cases in a single box. The development was prompted by a United States wireless network operator’s publication of a Host Device Certification Test Plan for manufacturers of IoT-enabled devices.

The new system (Figure 7) is made up of an R&S CMW290 functional radio communication tester and the R&S CONTEST sequencer software. The software runs provider-specific RF, protocol, and performance test cases—fully automatically and with reproducible results. Users, even those without programming knowledge, can create their own test plans with the software’s drag-and-drop function.

Courtesy of Rohde & Schwarz

The goal of the system is to support manufacturers who want to integrate wireless modules into their products and who now face completely new test requirements as network operators prepare their networks for a virtually unending number of IoT wireless modules, with a focus on device categories Cat 1, Cat M1, and Cat NB1. With the R&S TS-290, Rohde & Schwarz said it is offering a flexible test system for Cat 1, adding that the R&S TS-290 will be capable of supporting future IoT tests from multiple network operators.

Toolkit for 802.11ax

Finally, in addition to upgrading its VirtualBench, National Instruments is addressing the latest in Wi-Fi test with its announcement in April of the WLAN Test Toolkit 17.0 with support for Draft 1.1 of the IEEE 802.11ax standard. Combined with NI’s second-generation vector signal transceiver (VST), the WLAN Test Toolkit 17.0 supports 802.11ax waveform generation and analysis for characterization, validation, and production test of products—such as RF front-end components, wireless modules, and user devices—that implement Draft 1.1 of the IEEE 802.11ax standard.

The WLAN Test Toolkit 17.0 empowers designers and engineers with the ability to generate and analyze a range of 802.11ax standard-compliant waveforms, including extended single-user, multiuser OFDMA, and multiuser MIMO with per-user configuration and measurement results. The toolkit helps users solve demanding new access-point test cases by generating signals that simulate multiuser environments, including per-user impairments. Engineers also can use the new software to generate trigger frames to test the real-time response of client devices and make power pre-correction and relative center frequency

measurements.

With the WLAN Test Toolkit 17.0 and second-generation VST, engineers can configure up to 8×8 MIMO systems in a single PXI chassis. Users also can expect EVM measurements better than -50 dB, leading to rigorous device characterization and reliable test results. Furthermore, engineers can control their systems with the toolkit’s generation and analysis soft front panels and benefit from extensive LabVIEW, C, and .NET system-design software APIs and sample code when programming and automating their systems.

The WLAN Test Toolkit 17.0 expands NI’s wide-ranging product portfolio for testing 802.11a/b/g/j/n/p/ac/ax, Bluetooth, 2G, 3G, 4G, FM/RDS, GNSS, and low-power IoT wireless standards. NI’s platform-based approach helps ensure that users can update their existing PXI RF test systems to support 802.11ax device testing with a simple software update and continue to do so as the 802.11ax standardization process evolves.

As this article was headed for print, NI convened NIWeek, where the company introduced LabVIEW 2017 as well as LabVIEW NXG, a version that bridges the gap between configuration-based software and custom programming languages. The company said the NXG version empowers domain experts to focus on what matters most—the problem, not the tool. A future article will offer more details.

Reference

- Nelson, R., “Boosting measurement capability from pocket to benchtop,” EE-Evaluation Engineering, April 2017, p. 18.

FOR MORE INFORMATION