10 Things You Must Know About Benchtop Digital Multimeters

Design engineers use digital multimeters (DMMs) almost every day. They’re the most commonly used instruments on any design engineer’s bench. A DMM could be utilized to make quick and simple voltage measurement or data log temperature measurements over time. Whatever the use, it must work.

The DMM is the workhorse of the engineering bench. In exchange for all of the work done by our DMM, we expect to do very little upkeep and maintenance in return. Despite the DMM being such a critical instrument on our bench, we spend very little time thinking about its importance. From concept to prototype, turn-on, and debugging, all the way through testing and validation, the DMM is ever-present through the entire product cycle.

In this article, we will take a closer look at the DMM. I’ve compiled a list of 10 things that you should know about DMMs. Whether you’re considering buying your next DMM or simply looking to get more out of the existing DMM on your bench, this article will explore topics that are applicable to you.

1. Bench vs. Handheld

Though this article will primarily focus on benchtop DMMs and not handheld DMMs, do keep in mind that many of the topics and concepts apply to both platforms. In most cases, a typical benchtop DMM will have higher accuracy, better resolution, more sophisticated system programmability, and more advanced functionalities compared to a handheld DMM.

A benchtop DMM is intended to be used either on a bench or in a system rack. It’s ac-powered, which means it must always be plugged into a wall, so it remains stationary. On the other hand, the handheld DMM is intended to be highly portable. It’s typically powered by batteries, which means it is not tied down to a wall socket. The accuracy, resolution, programmability, and functionalities on a handheld is typically lower than that of a benchtop DMM. Many technicians and electricians use handheld DMMs because of their portability and simple functions. Many engineers and designers prefer benchtop DMMs for their accuracy and sophisticated measurement functionalities.

Connectivity is a big distinguishing factor between benchtop and handheld DMMs. Some handheld DMMs provide very simple USB or Bluetooth connectivity and mobile application. Benchtop DMMs typically offer more options in wired connectivity, such as LAN, USB, or GPIB, as well as software drivers. This allows for a sophisticated level of automated testing and software control.

If automated testing and remote programmability are extremely critical in your use model, go with a benchtop DMM. You will have much more flexibility in using a PC software or custom program to control a benchtop DMM. An additional bonus is that since benchtop DMMs are generally less portable (since they’re typically tied down by a power cord and a wired connection to a controller), they tend to stay on your bench a lot longer, since it’s more difficult for colleagues to take it off your desk and borrow it. From here on in, the term DMM will specifically refer to benchtop DMMs, not handheld DMMs.

2. Digits, Accuracy, Resolution

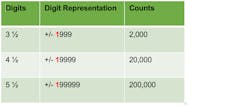

To understand digits, accuracy, and resolution, it’s important to begin by looking at the most common DMM question: What does that half digit mean? This question comes up very frequently and is typically the first thing you will learn about a DMM. For most DMMs, it’s printed right on the front panel next to the brand and model. The table illustrates the relationship between digits, digit representation, and counts.

This table highlights the number of DMM digit specifications with their representation and count.

For a 3½-digit DMM, the half digit is the most significant digit (in RED). A 3½-digit DMM offers plus or minus 2000 counts since the digit representation could be 0000 to 1999. A 4½-digit DMM offers plus or minus 20,000 counts and so on. The digits translate directly into counts that tell us about the resolution of the DMM. It’s not directly related to accuracy, which is a different specification. It’s a common misconception that digits and counts are the accuracy specification of a DMM.

Accuracy, on the other hand, tells us how close the measured value comes to the actual value of property being measured. It’s typically defined as a range with a lower bound and upper bound. Different brands specify accuracy differently, though, so it can get complicated. The bottom line is that it ultimately translates into a range of possible returned measured values. Accuracy and resolution together give the user a big picture of the quality of measurements one can expect from a DMM.

3. Visualization

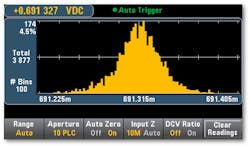

How do you want to see your measurements? A key consideration for a DMM or any instrument is how it displays the data. By default, we expect a numeral display on a DMM. Many advanced DMMs also offer sophisticated features like trend charts (value vs. time) and histograms (Fig. 1). Some DMMs will returned digitized values over the communication ports, such as a LAN, USB, or GPIB, enabling the user to do post analysis on a separate platform like Excel. On a crowded bench, it’s critical to have a DMM that stands out and displays its measurements in a clear and easy to read manner.

1. Histograms can provide users with more information in a compact display.

DMMs can offer graphic capabilities, e.g., trend and histogram charts, allowing for quick insight into the measurement. The 4.3-in. color graphical display makes monitor and statistical analysis easy and intuitive (Fig. 2).

2. Large color graphical displays on a DMM, like Keysight’s Truevolt family, make it easier monitor and present statistical analysis.

4. Secondary Measurements

Traditionally, DMMs have been used primarily to take a single measurement. In some cases, however, we want the ability to see more than one type of reading. This will offer complementary information that provides more meaningful insight. With the right architecture and design, some advanced DMMs can now display secondary measurements.

One application where this might come in handy involves measuring temperature using a thermistor connected to a DMM. If there’s a discrepancy in the temperature readings, an engineer might be interested in also looking at the variation in the thermistor’s resistance to make sure it is within range. Since the temperature reading is a function of the voltage reading in a thermistor, the resistance will yield a whole lot of insight into any anomaly.

Another application is taking measurements on a noisy low-frequency signal. In doing so, we might be interested in looking at both the dc and ac component at the same time. Some DMMs offer a secondary measurement feature that allows for more than a single type of measurement to be taken and displayed at a given time.

5. Simple DC Power Measurements

Power measurements are critical in many test applications. For those without a power meter, the DMM has traditionally been the instrument of choice to make such measurements. A true power measurement requires both voltage and current to be measured simultaneously, since power is voltage multiplied by current.

While most DMMs can measure both voltage and current, they typically can’t measure both simultaneously. However, by using a few clever techniques, we can get around this issue and get a power measurement from a DMM. One such technique uses the math function. Assuming the voltage in the circuit being measured remains steady (this is the case in a lot of setups), your DMM can use the math function to multiply the known (pre-determined) voltage by the measured current. This will yield a power measurement in watts that’s displayed on the front panel. It’s not a true power measurement from simultaneously measured voltage and current readings, but it makes the best of what a single measurement system on a DMM can do.

The Keysight Truevolt DMM has a special feature to obtain simultaneous voltage and current readings. If the sense terminals aren’t in operation, you can use it to make a secondary voltage measurement in a circuit while the primary terminals are measuring across a 1-Ω resistor in series with the circuit. This gives you simultaneous voltage and current measurements. Some restrictions to this feature do apply, but for basic power measurements, it’s a handy feature. Keep in mind that it’s a unique feature only available on Truevolt DMMs.

6. Low-Current and Dynamic-Current Measurements

You need to be aware of the level of current-measurement accuracy needed for your measurement applications. Measuring current on a semiconductor device requires a much higher level of current-measurement accuracy compared to other applications, say, measuring current flowing out of a car battery. On average, most 6½-digit DMMs can measure down to the 1-mA current range. A small number of advanced models will allow you to measure down to the 1-µA range.

Also, note that burden voltage can arise as an issue when measuring low current. DMMs measure current by using a shunt resister. Burden voltage is the voltage across a shunt resistor in series with a circuit. Burden voltage is a concern when measuring very sensitive components. One method to offset the burden voltage is by setting the voltage slightly higher on your power source.

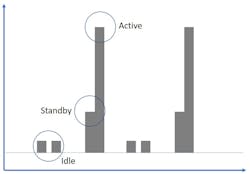

Measuring dynamic current is a complicated task. This is due to the change in measurement ranges. Figure 3 shows a typical current profile of a battery-powered wireless communication device. The current draw here depicts a wide range of idle, standby, and active modes. The dynamic range of the current is large because the operating currents are drawing approximately 30 to 40 mA, while the idle currents are only 1 to 10 μA.

3. Measuring dynamic current is a complicated task. A typical current profile of a battery powered wireless communication device has a wide range of idle, standby and active modes.

The traditional method to obtain accurate readings is to take multiple reading sweeps at each range. This means each sweep will capture a single operating mode (idle, standby, active). At the end of each sweep, it’s up to the user to piece together the measured results and perform analysis, which is typically a multi-step process. Even DMMs that boast of an auto-ranging functionality will not yield perfectly seamless results. It will typically miss or skip measurement points on a fast dynamically changing waveform.

7. Measuring Difficult AC Signals

Usually, ac voltage signals are depicted in textbooks as perfect sinusoidal waveforms. In the real world, though, ac voltage signals and currents are far from perfect. They come in widely varying shapes and values. Digitizing a small portion of an AC waveform allows you to see a few short cycles. If you’re interested in RMS amplitude or frequency measurement over a long period of cycles, you will need to make ac measurements.

The crest factor specification is important to ac measurements. The crest factor is the ratio of peak value to RMS value in a waveform. A DMM’s crest factor represents how much of the total energy from the peak value will be included in an ac measurement. Ideally, you would like to include as much of the total energy in the waveform as possible to get an accurate measurement. If a DMM has a crest factor rating of 10, you can measure an input signal whose peak value is 10 times larger than the rated range value. Another area where crest factor is important is when you measure pulsed signals. That’s because it can be challenging to accurately read the RMS voltage/current when a signal level with an “on” period is followed by a period where no activity occurs.

8. Temperature Variations and Auto Calibration

If you look at a DMM datasheet, you will normally find accuracy specifications change from the time of calibration (Fig. 4). The accuracy worsens as more time elapses from the time of calibration. To illustrate, refer to the datasheet for the new 34465A Truevolt DMM (Fig. 3, again). In addition to the 24-hour, 90-day, and 1-year specification columns, you will see a temperature coefficient (TC) column. If the temperature of your measurement environment—the ambient temperature at which the DMM is operating— is not the same as the temperature of the DMM calibration environment, then you need to consider the TC error adjustment.

4. A DMM datasheet will provide accuracy specifications change from the time of calibration. Accuracy gets worse as more time elapses.

An example is when a unit is calibrated at 22°C but operating at 40°C inside a test system. Such a rise in temperature is common in test sets inside of a system rack. We need to add in error due to TC specifications. Some high-end DMMs have an autocalibration (ACAL) feature, which greatly reduces temperature drift error. ACAL is the built-in ability of a DMM to compensate for temperature drift and internal errors. Autocalibration is also known as self-calibration. If you’re working in an environment where the ambient temperature is different than the recommended temperature range, it’s a good idea to find a DMM with this ACAL feature.

9. Triggering

Triggers allow you to start measurements based on the detection of a trigger source. Trigger sources include continuous, external triggers such as BNC or BUS; level triggers, based on the signal crossing a certain threshold; or exhibiting triggers, which have a positive/negative slope. In most advanced DMMs, you can program a trigger delay and capture multiple sample periods surrounding a trigger event. The results are digitized values returned over the I/O interface or displayed as a trend chart on the front panel.

Triggering is an important function to consider before purchasing a DMM. Many battery-powered wireless devices exhibit pulsed signal characteristics in their current consumption. Triggering makes capturing these pulse signals much easier.

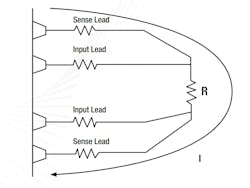

10. 4-Wire Measurement

Generally, there’s resistance in the input leads of a DMM. This resistance causes a voltage drop and yields inaccuracies in measurements. The solution to this voltage-drop problem is 4-wire sensing. Perform your measurements right at the device under test, hence bypassing the voltage drop introduced by the input leads.

When you use 4-wire measurements, you ensure a greater level of accuracy compared to traditional 2-wire measurements. Most high-end benchtop DMMs perform reliable, accurate 4-wire measurements (Fig. 5), while the majority of handhelds only perform 2-wire measurements. If you’re working with applications requiring that extra level of accuracy, select a DMM that supports 4-wire measurements.

5. A 4-wire measurement provides more accurate results.

Addressing all 10 of these factors, Keysight developed the Truevolt Digital Multimeter series. Truevolt technology starts with an analog-to-digital converter that enables a patented metrology-grade architecture. Using this architecture, this family of DMMs delivers a good balance of measurement resolution, linearity, accuracy, and speed.

Steven Lee is an Application Engineer at Keysight Technologies Inc.