Space-Enhanced Plastic ICs Boost LEO Satellite Reliability

Members can download this article in PDF format.

Low-Earth-orbit (LEO) satellites are swarming into space to provide enhanced communications, connectivity, and imaging capabilities worldwide. Unlike traditional satellites, which typically circle the earth in synchronous orbits more than 22,000 miles up and are designed to last 10 years or more, LEO satellites operate within 1,300 miles of the earth’s surface and may have expected lifetimes of less than seven years.

LEO satellites require small, integrated components to save circuit-board space. These components must be available with short lead times to meet the fast turnaround requirements of the LEO satellite market, and they must reliably withstand the harsh radiation and thermal-cycling conditions of space. It’s also mandatory that they be able to operate on low power to minimize satellite battery weight and solar-array size.

Plastic ICs are attractive options, although they present challenges related to radiation tolerance as well as process and material variations. In addition, plastic packages may exhibit outgassing.

SEP Fabrication, Assembly, and Test

Texas Instruments addresses the challenges that LEO satellites present with its space enhanced plastic (SEP) portfolio. TI manufactures SEP devices at a single fabrication, assembly, and test site to eliminate site-to-site variations in materials, electrical specifications, and radiation tolerance, measured in radiation absorbed dose for silicon, or rad(Si). The company tests each wafer lot of SEP devices to a 20-krad(Si) total-ionizing-dose (TID) assurance level or higher. TI typically characterizes devices from 30- to 50-krad(Si) TID levels during qualification.

To enhance reliability, SEP devices employ gold bond wires to eliminate the bond-integrity issues associated with copper. In addition, the devices don’t use terminations with high tin content to minimize the risk of tin-whisker formation.

The devices also are qualified over a −55 to +125°C temperature range and undergo highly accelerated stress testing. They come with detailed reports, including a radiation report for TID and a radiation report for single-event effects. Furthermore, there’s an outgassing and reliability report that provides product-flow and traceability information to expedite circuit-board qualification and reduce the need for external qualification efforts.

SEP Portfolio

Devices in TI’s SEP portfolio range from pulse-width-modulation (PWM) controllers to fully differential amplifiers (FDAs). For example, the TPS7H500x-SEP family of high-speed radiation-tolerant PWM controllers have a 0.613-V internal reference with an accuracy of +0.7%, –1% and a configurable switching frequency up to 2 MHz. Each device offers programmable slope compensation and a soft-start function. Their features combine to make them useful for the design of dc-dc converter topologies targeting space applications.

TI also offers synchronous step-down converters, including the TPS7H4010-SEP, a 3.5- to 32-V, 6-A version, and the TPS7H4003-SEP, a 3- to 7-V, 18-A model. Available SEP regulators include the TPS73801-SEP, a 1-A, low-noise fast-transient-response LDO model, and the TPS7H1210-SEP, a 1-A low-noise, small-form-factor negative linear regulator. Among the data-communications devices in the SEP portfolio are the SN55HVD233-SEP 3.3-V CAN transceivers as well as the SN65C1168E-SEP RS-422 dual differential drivers and receivers.

Other members of the SEP portfolio include PS7H2221-SEP small-form-factor 1.6- to 5.5-V, 1.25-A load switches; TL7700-SEP 40-V supply-voltage supervisors; LMX2694-SEP 15-GHz RF synthesizers; INA240-SEP 80-V low/high-side current-sense amplifiers; and TLV1704-SEP 2.2-V to 36-V four-channel comparators. In addition, there are the ISOS141-SEP 100-Mb/s quad-channel digital isolators; ADC128S102-SEP eight-channel, 50-kS/s to 1-MS/s, 12-bit analog-to-digital converters (ADCs); and LMH5485-SEP FDAs.

FDAs Combine with ADCs in Space

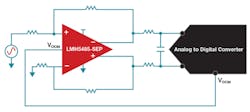

With regard to these last two product categories, ADCs and FDAs can team up to address LEO satellite signal-chain challenges. ADCs for such applications tend to have fully differential inputs to take advantage of differential signals’ high fidelity and extended dynamic range. However, some sensors and other devices on a satellite may not provide differential outputs. FDAs can convert the single-ended signals from such devices to differential versions, saving the board space that would be required for a two-amplifier solution.

Figure 1 shows TI’s LMH5485-SEP FDA driving a fully differential ADC. Using the FDA will provide a reduction in noise compared to an implementation using two single-ended op amps. Furthermore, the single-FDA architecture reduces noise by a factor of 1/√2 compared with a two-op-amp approach. The LMH5485-SEP also includes a high-impedance common-mode input pin (labeled VOCM in the figure) that enables a precise match to the ADC input common-mode voltage.

FDA Details

The LMH5485-SEP offers a variety of features that suit it for use in power-sensitive data-acquisition systems operating at frequencies greater than 10 MHz. It features a gain-bandwidth product of 850 MHz, a current rating of 10.1 mA (from a 2.7- to 5.4-V power supply), a broadband input voltage noise of 2.4 nV/√Hz, a slew rate of 1,300 V/µs, and an offset drift of ±0.5 µV/°C (typical). It comes in a 3- × 3-mm very thin shrink small-outline package (VSSOP) and meets TI’s SEP qualification requirements.

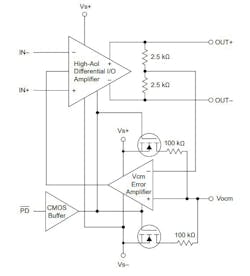

As shown in the Figure 2 functional block diagram, the device includes a high open-loop-gain differential amplifier and a common-mode-voltage (VCM) error amplifier. If the VOCM pin is left unconnected, the two 100-kW resistors that connect to VOCM establish a common-mode voltage midway between the power-supply high and low voltages (VS+ and VS-).

A power-down mode limits current levels to 2 µA (typical) when the power-down control pin /PD asserted low (within 0.7 V of the negative supply). In power-down mode, switches open to prevent bias current from flowing through the two 100-kW resistors connected to the supplies and VOCM. For normal amplifier operation, /PD must be asserted high. It can’t be left floating because the device has no internal pullup or pulldown resistors.

Conclusion

LEO satellite designers face many challenges related to cost, size, performance, temperature range, and radiation tolerance when choosing components. TI’s SEP portfolio includes a wide selection of space-ready plastic devices ranging from ADCs to FDAs to help meet the challenges of designing cost-effective, high-performance, and reliable LEO satellites while accelerating launch times. TI offers a wide range of support and comprehensive reliability reports to help ensure success.