LED Pixel Light Revolutionizes Automotive Front Lighting

Only 25% of travel by car takes place in the hours of darkness, yet over 40% of all major accidents (with fatalities or serious injuries ensuing) occur during this time, according to figures published by the U.S. National Highway Traffic Safety Administration (NHTSA) and the European Commission (EC). This has spurred on automobile manufacturers to find possible solutions, culminating in the implementation of more sophisticated lighting arrangements into their latest models.

The industry took a major step forward in advanced front-lighting systems (AFS) with the arrival of Pixel Light, which dramatically improves driver/passenger/pedestrian safety. Conventional incandescent or high-intensity discharge (HID) lamp-based AFS implementations rely on motor-controlled beam adjustment. Pixel Light, on the other hand, controls multiple LED emitters, providing a far more flexible and operationally efficient approach. However, cost-effective, modular electronics will be required to drive and control AFS systems based in this technology.

Pixel Light Prowess

Through Pixel Light, it’s possible to generate any particular beam-shape required to assist with the driver’s visibility. Discrete LEDs are turned on, off, or dimmed to form the most suitable beam at any stage of the journey. When combined with the vehicle’s navigation system, lighting can be manipulated to illuminate the curves in the road, as well as raise or lower when negotiating hills. This technology, when linked together with camera systems, also enhances illumination of road signs, pedestrians, and other objects in the driver’s line of sight, while minimizing the glare of oncoming traffic (Fig. 1).

Related Articles

• The Right Resistors Enable LED Lighting

• Understanding LED Application Theory And Practice

• LED Lighting Depends On Drivers

Vehicle lighting has gradually migrated from xenon-based lamps to solid-state technology over recent years. Initially, the changeover concentrated on areas such as cabin illumination, parking lights, etc. More recently, though, it’s being used in the front lighting of mid-/high-end car models (and now becoming an option in lower end cars). Two main reasons behind the switch are the greater reliability and lower power consumption offered by LEDs. However, perhaps the overriding benefit is the lighting system’s versatility made possible by the LED’s adjustable output power, which can ultimately have a profound effect on automotive safety.

Pixel Light’s superiorfunctionality and fast switching means that multiple blanking zones are able to be placed into the beam. The beam can be shaped or bent as required with a higher level of precision and without the need for shaping or bending motors, thereby simplifying system design and lowering the overall bill of materials.

Pixel Lighting Topologies

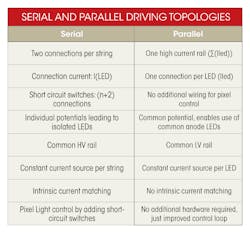

Pixel Light-based AFS systems employ one of two basic drive topologies: serial and parallel (see the table).

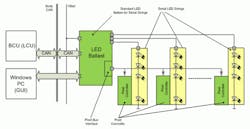

The topology for a parallel drive includes a high-power buck converter that acts as the current or voltage source (Fig. 2).

The variation in the electrical characteristics of each LED has a significant impact on lighting-system performance. For example, a considerable difference in the LEDs’ anode-cathode voltage can trigger high levels of heat dissipation, which raises power consumption and requires additional heatsinking. Until better LED matching becomes available, this topology will likely experience only limited success in AFS applications.

In a serial drive, an LED string driver provides a constant current source with a high output resistance (Fig. 3).

Short-circuit switches disable individual LEDs so that the beam can be shaped as needed. It’s possible to avoid the power-consumption and thermal-management issues inherent in parallel topologies with system partitioning, if a companion chip is added into the circuit.

To illustrate, a driver circuit using a serial topology with system partitioning incorporated ON Semiconductor’s NCV78763 buck-boost LED driver IC as a power-current source (Fig. 4).

The IC is complemented by a combined pixel-controller/companion chip (Fig. 5). Such a modular approach lowers the component count and simplifies the implementation process, thus accelerating time-to-market.