Low Power Microcontroller Has Up To 128 Kbytes Of FRAM

Texas Instruments (TI) usage of FRAM has significantly improved the power utilization of many microcontroller applications (see “FRAM Microcontroller Targets Low Power Applications”). These micros still have on-chip SRAM but they replace flash storage with FRAM that has a faster write speed and does not suffer from flash memory’s limited write lifetime. FRAM lifetime is rated in trillions of cycles. This allows FRAM to be used for code and data (see “Microcontroller Utilizes FRAM For Code And Data”).

The challenges for developers in the past has been to choose an FRAM-based MSP430 microcontroller that had the proper resources for an application but the selection was limited in terms of memory space and often peripheral complement. The new MSP430 FR59xx/69xx series (Fig. 1) greatly expands the number of SKUs. They also fill out the peripheral and memory complement including support for a 12-bit 16-channel ADC, LCD interfaces and 256-bit AES encryption hardware accelerator.

FRAM-based solutions are also much better for in-field upgrades that are more common with the rise of the Internet of Things (IoT). The write bandwidth of 8 Mbytes/s is significantly faster than flash memory that is about 14 Kbytes/s. FRAM also eliminates flash memory’s pre-erase cycle. The higher bandwidth allows real time logging for many applications. The 2 Kbytes of SRAM is only needed for data that needs even more throughput.

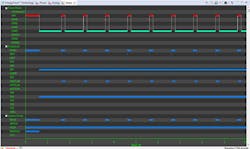

Another part of TI’s latest release is the addition of the EnergyTrace++ power diagnostic technology. This allows a developer to trace power usage and power modes (Fig. 2).

EnergyTrace++ tracks the entire system including peripherals. This allows it to deliver more power information than other systems that simply provide overall power utilization. TI can also provide cumulative information (Fig. 3) in addition to detailed trace information.

The FRAM MSP430 family is supported by TI's Code Composer Studio and IAR Systems' IAR Integrated Development Environment (IDE). This includes the EnergyTrace++ support.

The MSP430 already targets low power applications. It uses only 100 µA/MHz when active. The real time clock (RTC) uses only 450 nA. The system can start up from standby mode in under 7 µs. The system has independent power control for the core and peripherals. The differential ADC also has a window mode. This allows the system to sleep while the ADC is active. The ADC only wakes up the system if a reading is outside the range of the window.

TI has a number of development platforms including the MSP430 FRAM Launchpad board (Fig. 4). It an MSP430 FR5969 FRAM microcontroller. It also has Launchpad-compatible headers on the top and bottom of the board.

The FR59xx series comes with up to 64 Kbytes of FRAM. The FR69xx is available with up to 128 Kbytes o FRAM. Both use a 16 MHz, 16-bit MSP430 core. Pricing for the FR59xx starts at $2.71. The FR69xx starts at $3.79. This is very close to flash-based solutions so developers can more easily justify the FRAM versions especially when power requirements are considered. The chips are available with an operation range of -40º to 85ºC and 1.8 to 3.6 V.

This expansion of the FRAM family moves FRAM microcontrollers from specialty applications to general use. FRAM has significant advantages which may make it the mainstream platform in the future.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.