This file type includes high resolution graphics and schematics when applicable.

Bob Pease and Reginald Neale exchanged letters back in 1989, and Neale was nice enough to send them to me recently. Of course, Bob had plenty of agreement and advice. He knew the difference between accuracy and precision.

My professor, James McLaughlin of Kettering University, knew the difference 40 years ago.1 “Football is a game of great precision and little accuracy,” he would say. He was referring to American football, where referees have a precise 10-yard chain to measure first downs. The measurement to a first down is precise because the chain is exactly 10 yards long. However, it’s inaccurate because a referee has to estimate the ball’s forward progress when he plops it down.

Related Articles

- What's All This Solenoid Driver Stuff, Anyhow?

- What's All This RIP (Rest In Pease) Stuff, Anyhow?

- A Trip To The Gun Show: Or, An Analog Parable About Precision Versus Accuracy

Bob mused on precision and accuracy in a series of articles that eventually became his book Troubleshooting Analog Circuits. He noted that engineers will trust a digital display more than an analog one. Like American football, the presence of those precise, crisp digits belies the fact that the number might not be accurate.

In 1989, engineer Reginald Neale wrote Bob, “You’re right. Most people, even technical people who should know better, tend to treat any numeric display as if it were engraved in stone, ignoring whatever imperfect mechanism generated the digits. Even when [numbers] scribbled in Jello would be more appropriate.”

In his distinctive scribble, Pease wrote Neale back, “Yeah, you are right about the ‘engraved in Jello’ Digital Displays.”

Regarding panel meters, Neale had mentioned how having precision without accuracy can help with relative measurements. “Even though you don’t have the accuracy, you still get the benefit of being able to make a change in your benchtop circuit of very nearly 0.001 instead of 0.01. So I don’t think the extra digit is silly, as long as you’re not paying a big premium for it,” he noted.

Neale has a valid point. While a panel meter might not be accurate to that last digit, if you change your circuit and the last digit moves, you can generally trust it. This is because measurement circuits tend to be monotonic. The reading doesn’t go down when the input goes up, so that last inaccurate digit can give you some relative information. Pease, ever the contrarian, jumped into the absolute domain. There, you are looking for a precise dc value, not some relative ac change. Pease responded at length:

“That’s my whole point about power supplies with the twin Digital Panel Meters: a 5% error doesn’t sound very bad at the 5-volt level – 4.7 or 4.8 or 4.9 or 5.1 or 5.2 – that’s not too weird. But, if I want to set a voltage to +24 volts, it would be nice to have less than one volt of uncertainty. Example: to set +24.0 & –24.0, should I have to trim one supply to +25.1 and the other –23.1 V, to get the +23.0 & –24.0? Or was that, vice versa? Naw – 5% is just too crude! I just bought a set of power supplies, made in Taiwan. Each dual supply has FOUR meters, two for V, two for I ….. and each meter has a trimpot. Now – one thing I did do was to check the settability of the pots – I was able to set the Vout to 1.00 V within ±0.030 V, also 2.00 ±0.030, 3.00 ±0.030, etc. – thus, there were no obvious flat spots or dead spots in the pot, and the resolution was better than 0.1% of full scale – 30 mV resolution out of 30 volts. Not bad for a single-turn pot. You’ll agree, some pots with course and fine aren’t any better than that.

“But So Far, I have not checked the calibration accuracy of those meters! So in the next few days I’ll ask my senior tech to set the meters at 10, 20, 30 V, and see what the DVM [digital voltmeter] says; Also, 1.0, 2.0, 3.0 Amperes.....

“Now, I like extra digits of resolution as much as anybody does...

“But – I just looked over the specs of the new Tektronix 6-digit DVM. The specs aren’t bad, but the linearity is ±10 ppm. Hell, on a 30-volt scale – that’s not necessarily 100 µV out of 10 V, that’s 300 µV out of 30 V, so there could be 300 µV out of 10 V.

“I prefer the HP3456/57 with 1 ppm, or 15 µV of nonlinearity on a 15-volt scale. Who says a 30 V is better than a 15-volt full scale? Maybe it is, maybe it ain’t.”

You can see what was so admirable about Bob Pease. He did not theorize or pontificate. He went out to the bench and measured things. I wish Pease would have mentioned which Tektronix DVM he was talking about. If Tek spec’ed it ±10 ppm of full scale, Pease is right in his analysis.

I found the DM5120 6.5-digit multimeter (Fig. 1). Page 1-4 of the manual for the DM5120includes that 10-ppm spec. It does not say if that is ±10 ppm. It does note that it is not on the full scale of the instrument, 300 V, but full scale of the range it is in. Pease is correct when he notes a 10-V reading is subject to the 10 ppm on 30 V, if this was the instrument he was referring to.

Pease was making a point by comparing disparate meters. The Tek DM5120 sold for $1989 when Pease wrote this letter.2 The HP 3456A was $4000 in 1985 and $6400 in 1993.3 You get what you pay for, so don’t slag my pals at Tektronix.

The HP (now Agilent) 3456A was a fine instrument (Fig. 2).

I am the proud owner of four of the later model, the HP 3457A (Fig. 3). Its 6.5-digit panel meter means it can display 1 µV and 1.999999 V without changing ranges. If you use the general-purpose interface bus (GPIB) on the back, you get 7.5 digits. That’s 1 µV to 20 V without pressing a button. Drop $5000 for a used Agilent 3458A, still in production, and you get 8.5 digits. That’s 1 µV to 200 V without changing ranges. If you’re using it for production test or anything important, you will want a brand-new one from Agilent costing $9267 (2013).4

My buddy, an ISO9000 consultant, thinks it is even more important to have the best, newest, test equipment in R&D. An old uncalibrated meter in production might miss a few bad units. A junker meter in your lab can result in the product being designed as 100% bad units.

So I think Neale is right that extra digits are useful for relative measurements, and Pease is right that accuracy is essential for absolute measurement. And I was right for snagging four 7.5-digit voltmeters for a few hundred bucks at a Dovebid auction.

Back in 1973, Professor McLaughlin had a policy on resolution and accuracy. Slide rules were still in use, but the handheld calculator had entered the classroom. A couple lucky students had HP35s. Realize that the $395 price in 1972 is $2141.93 in 2012 dollars. McLaughlin gave us problems with numbers having three signification digits, that is to say, three digits of accuracy.

Those kids with calculators would poke their buttons and then write down an answer with all the digits the calculator showed—10 digits of resolution. But the accuracy of the answer was really three digits. So, McLaughlin would flunk them for the problem—0 points. Oh, how those scions of industry would howl. Nope, not even partial credit for them, not from McLaughlin. We hoi polloi with our slide rules were spared, but we sure remembered the point.

While on the subject of power supply meters, I should repeat what Bob Pease’s protégé, Paul Grohe, told me last week. Now at Texas Instruments, Grohe said, “Dual supplies should have two voltmeters and two ammeters and no switch to change between amps display and volts display.” I know some engineers who prefer antique power supplies with analog meters (Fig. 4). They say they can see a needle move much easier than read a flickering digit. They can also see variations or oscillations easier on a needle meter.

Spice

The exchange between Neale and Pease also touched on Spice. Pease’s disdain for engineers who put full faith in simulation is well known. Neale recounted a story:

“People do get carried away with computer simulation. Back in the sixties there was a story circulating about the Apprentice Engineer who was playing with the plant's new analog computer. He ran up to the Chief Engineer, waving a sheaf of printouts ‘Look,’ he said excitedly. ‘We’ve come up with a simulation of our power plant heating and air conditioning system which will double the plant’s efficiency!’ The Chief Engineer studied the printout for a few moments. ‘Yes,’ he said, ‘but look here,’ and he pointed to the flow diagram. ‘This 17°Fwater is going to be awfully hard on the pumps!’”

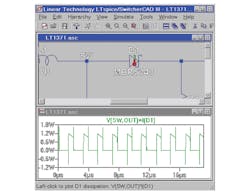

I had not heard this story, but I have no doubt it was based on a factual encounter. I made a serious error in the Spice simulation in my last article. I forgot to check for the base-emitter reverse breakdown of the transistor I used. I was just trying to show some waveforms to demonstrate the principles, but it was still sloppy to call out a part that would degrade or blow up in a real circuit. A diligent reader noted the error. Spice gave no indication the part was unsuited to the application. This was why Pease was so adamant about building circuits on a bench, not in a computer screen.

In response to Neale’s story, Pease noted:

“Now, your comment about the 17°F water – I would immediately reply, ‘Oh, the +17°F water goes through the pumps really smooth, after I add a little alcohol or propylene glycol.’ And then the crusty old-timer would say, ‘Now son, tell me, where are you going to get all that cool water on a hot day when we need it??’

“That is a tougher question to answer! Heck – the heater on my VW works Real Well in the summer. (Especially if I can’t shut it off.) It’s only in the winter that it doesn’t work so well. I know places in Dakota or Minnesota where you can get all the coolant you want at ~+17°F in the winter. It’s only in the summer that it’s expensive!”

Spice is getting better. A buddy told me about a Spice package that puts little red wiggles around an IC when its power rating is exceeded. Like many engineers, I have had Spice runs with an IC dissipating more power than it can handle. I thought my circuit was fine, but I forgot to put a power marker on the part (Fig. 5). I got the real part’s logo burnt into my finger when I touched it on the breadboard.

The problem is related to what Reginald Neale noted at the beginning of the article, that people will trust a pretty digital display even if it’s untrustworthy. Engineers will trust a pretty Spice graph even if it disagrees with reality. I have had an IC designer tell me my evaluation board must have some deficiency or “circulating currents” when the real problem was that he never used vertical bipolar inter-company (VBIC) models in his simulation. That would have agreed with my tests that showed an oscillator frequency changing two octaves over temperature.

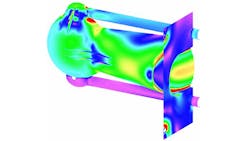

Mechanical engineers can be just as foolhardy. I interviewed Tom Rummage, a senior application engineer at Vishay, for an article about strain gauges.5 He would show engineers a broken part they had designed. The engineers blamed Rummage. He must have tested it wrong, or there must be a bad casting, or inferior materials. The problem was the simulations the engineers ran did not account for the residual stress in the part caused by the casting cooling from a molten state. Finite element simulations on a computer screen are so pretty, we want to believe they are always true (Fig. 6).

User Interfaces

“Your frustration with the menu burden of these wonderful new instruments is right on target. One thing that I detest intensely—and seems to occur with increasing frequency—is staring blankly at a screen or cursor, knowing full well that the reason it obstinately refuses to do your bidding is almost certainly a consequence of your imperfect understanding of its functioning, and possibly also of your failure to read the manual all the way through... the next time you have a spare week,” Neale wrote to Pease.

“Also, some of the general principles behind specific points you have raised are discussed with uncommon goodsense in a book called The Psychology of Everyday Things. I can’t recommend it too highly,” he added.

I too have a longing for a time when it did not seem I was playing some video game coordination test every time I use a product. I detest power buttons you have to hold down for 534 ms before the product comes to life. And if you hold it down too long, the dang thing turns on, then goes off as you helplessly watch in disbelief. Once on, the very same unlabeled grey-on-black on button is now an off button. Have these idiots never heard of a switch?

Equally frustrating is waiting for test equipment and every other appliance on earth to “boot up.”Most oscilloscopes are just Linux or Windows computers with an acquisition deck. It’s like we have gone back to the era of vacuum tubes and we have to wait for equipment to warm up. I do that for my Strobotac, but at least it’s worth the wait (Fig. 7). With these computer-based instruments, your wait is rewarded when you get to poke and prod and navigate through a blizzard of screens and menus and dialog boxes.

I had some real joy when my buddy Marty McGrath showed me the now defunct Bantam Instruments spectrum analyzer. He didn’t design it with an embedded computer. He programmed an MC68332 to run things. There are a few milliseconds of splash screen, and then a trace is crawling across the screen. Marty should get a Nobel Prize. It’s a shame the product never made it, but I hear Rohde & Schwarz has a similar instrument. It’s 10 times the cost, but you never go wrong with high-quality test equipment.

Bob Pease was always open to learning things. He took Neale’s recommendation to heart, replying: “You mention The Psychology of Everyday Things. I shall have to look into that, pronto! Thanks for the tip.” And I think we all owe Bob and Reginald a hearty thanks for all the tips they have shared with us.

The pdf file of Bob’s and Reginald’s original letters can be downloaded here.

References

1. Professor McLaughlin, https://www.kettering.edu/faculty/dr

2. Tektronix DM5120 6-1/2 Digit Multimeter, http://www.barrytech.com/tektronix/tektm500/tekdm5120.html

3. “A history of the HP 3456A,” http://tech.groups.yahoo.com/group/hp_agilent_equipment/message/31984

4. 3458A Digital Multimeter, 8½ Digit, http://www.home.agilent.com/en/pd-1000001297%3Aepsg%3Apro-pn-3458A/digital-multimeter-8-digit?&cc=US&lc=eng

5. “Stress out; strain gauges in,” Paul Rako, EDN, May 28, 2009, http://www.edn.com/design/sensors/4313669/Stress-out-strain-gauges-in

About the Author

Paul Rako

Creative Director

Paul Rako is a creative director for Rako Studios. After attending GMI (now Kettering University) and the University of Michigan, he worked as an auto engineer in Detroit. He moved to Silicon Valley to start an engineering consulting company. After his share of startups and contract work, he became an apps engineer at National Semiconductor and a marketing maven at Analog Devices and Atmel. He also had a five-year stint at EDN magazine on the analog beat. His interests include politics, philosophy, motorcycles, and making music and videos. He has six Harley Sportsters, a studio full of musical instruments, a complete laboratory, and a video set at Tranquility Base, his home office in Sun City Center Florida.