COVID Tester Uses Laser-Drilled, Coated Graphene Sensors

What you'll learn:

- How does the rapid-response detection unit work?

- What components were used to create the RapidPlex unit, and how was it built?

It would be a major advance if there was a basic test instrument or front end that could determine if someone harbors the COVID-19 virus—and soon that might be a reality. A team at the California Institute of Technology (Caltech) has developed a standalone electronic-based unit with highly tuned, specific biochemical tags that may enable “on the spot” testing for the presence of the virus—even in persons who show no symptoms. Results would arrive in about 10 minutes.

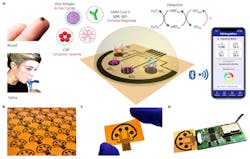

The team’s SARS-CoV-2 RapidPlex unit uses a combination of multiple, low-cost sensors, followed by data processing and reporting to the user’s smartphone and even linked telemedicine aspects (Fig. 1).

These sensors can detect extremely low levels of specific components in blood, saliva, or sweat. The unit electrochemically quantifies three important molecular biomarkers:

- The SARS-CoV-2 nucleocapsid protein (the virus itself)

- The anti-spike immune response proteins IgG and IgM (antibodies to the virus)

- The C-reactive protein (CRP) (inflammation linked to infection severity)

- The unit rapidly detects these biomarkers as well as high molecular sensitivity and selectivity. The results of the pilot study indicate that it can successfully detect these biomarkers in COVID-19-positive patient serum and saliva samples, and CRP results are well-correlated with the severity of symptoms.

Important disclosure: So far, the device has only been tested in the lab with a small number of blood and saliva samples obtained for medical research purposes from individuals who have tested positive or negative for COVID-19. Lead researcher Prof. Wei Gao noted that although preliminary results indicate that the sensor is highly accurate, a larger-scale test with real-world patients rather than laboratory samples must be performed to definitively determine its accuracy.

In addition to the deep understanding of the relevant and highly sophisticated biochemistry, the key to the viability of this instrument are the sensors and their coatings. The platform uses captured antigens and antibodies immobilized on graphene electrodes that have been laser engraved to create micropores. This low-cost, mass-producible process creates a large surface area on the sensor to make it sensitive enough to detect compounds that are present only in minuscule amounts.

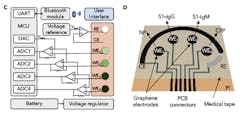

The RapidPlex sensor array has four graphene working electrodes (WEs), an Ag/AgCl reference electrode (RE), and a graphene counter electrode (CE). All of them are patterned on a polyimide (PI) substrate via CO2 laser engraving, which is a fast, high-throughput, and cost-effective production method (Fig. 2).

Graphene’s superior properties of high charge mobility and surface area, combined with the high sensitivity and selectivity of sensing strategies involving both capture and detector receptors, should make this device a convenient tool for the rapid, accurate, and stage-specific detection of COVID-19 infection in blood, as well as in non-invasive biofluids such as saliva.

The sensor coating uses 1-Pyrenebutyric acid (PBA) as the “linker” to anchor the required receptors to the graphene layer. The pyrene units of PBA strongly interact with graphene layers in the way that graphene’s original structure and properties are well-maintained. This was combined with an optimal blocking strategy for undesired reactions and affinities, so that the PBA can be used to immobilize specific biomolecular probes (e.g., antibodies, proteins).

The performance and selectivity of each constructed biosensor was individually and carefully evaluated, after which the team demonstrated the multiplexing capabilities of their four-working-electrode (4WEs) graphene-array device (Fig. 3). Advanced techniques including differential pulse voltammetry (DPV) and open-circuit potential-electrochemical impedance spectroscopy (OCP-EIS) were used to electrochemically characterize the sensor’s processes.

In use, amperometric readings (where an optimal potential is applied to the electrochemical cell and a corresponding current is obtained due to a reduction or oxidation reaction) from the four channels are taken concurrently. Data is transmitted to a user device over a Bluetooth link.

From an electronic-design standpoint, once you have finished with issues related to the sensors—their fabrication, coating, calibration, and the analog front end—the remaining circuitry is fairly straightforward. The electronic system, including the printed circuit board and a lithium-ion polymer battery, measures 20 × 35 × 7.3 mm and can perform measurements continuously for over five hours on a single charge.

Details of the project are provided in their paper “SARS-CoV-2 RapidPlex: A Graphene-Based Multiplexed Telemedicine Platform for Rapid and Low-Cost COVID-19 Diagnosis and Monitoring,” published in Matter (it’s also posted here if there’s a problem with the link at Matter), along with Supplemental Material. But be aware that about 95% of the paper is about the complex biochemistry, fabrication, and performance of the sensors, while the fairly standard electronics are reduced to one paragraph. However, the paper will certainly give you an appreciation of the impressive level of infectious biology and biochemistry knowledge needed (both theoretical and practical), plus sophisticated wet-lab insight and hands-on expertise required on projects such as this one.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.