Members can download this article in PDF format.

Safety, reliability, and functionality are all critical to the success of electric vehicles (EVs) and hybrid-electric vehicles (HEVs). Effective isolation strategies are key to optimizing these three areas.

In many high-voltage automotive systems, isolation is a functional requirement that can be leveraged to enhance safety by protecting operators and service technicians from electric shock. In addition, isolation can improve reliability by preventing overvoltage and overcurrent conditions from damaging sensitive electronic components. To successfully deploy isolation strategies, you will need an understanding of the types of isolation available and the levels of protection they provide.

Sponsored Resources:

- Achieve Higher-Reliability Isolation and Smaller Solution Size with Solid-State Relays

- Reliable Fault Detection in High-Power Systems

- Introduction to Isolation

Solid-State Relays

One method of providing isolation is to use a relay—a key component that enables a low-voltage signal to control high-voltage systems and subsystems. Electromechanical relays (EMRs), photorelays, and solid-state relays (SSRs) can all serve in automotive applications.

The EMR has been the traditional choice. EMRs feature very low levels of on-resistance, but they’re comparatively large and power-hungry and exhibit slow switching speeds (with switching times in the 5- to 15-ms range). In addition, because they have moving parts, they may face reliability issues due to the shock and vibration found in automotive operating environments. The photorelay has no moving parts, but it is subject to deterioration of its internal LED.

In contrast, SSRs offer performance, cost, and reliability benefits while being able to switch in microseconds. Texas Instruments offers SSRs featuring basic and reinforced levels of isolation. Specific TI SSRs include the TPSI2140-Q1, a 1,400-V, 50-mA isolated switch with 2-mA avalanche rating.

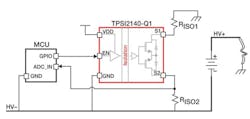

Qualified for automotive applications in accordance with the AEC-Q100 grade 1 standard, the TPSI2140-Q1 includes an SiO2-based capacitive isolation barrier. The primary side requires only 7.5 mA of input current, allowing you to use a microcontroller unit (MCU) to drive the device’s EN pin (Fig. 1), eliminating the need for external control circuitry. Because the device integrates both power and signal transfer across its isolation barrier, you needn’t include a secondary bias power supply in your design, saving cost and space.

Reliable Fault Detection

Fault detection is a key requirement for many automotive systems including EV chargers, traction inverters, and dc-dc converters. Fault-detection circuitry monitors voltage, current, and temperature to diagnose power-system problems such as overloads. Should a system fault occur, the host MCU can take protective action, such as turning off or modifying the switching characteristics of the system’s power transistors.

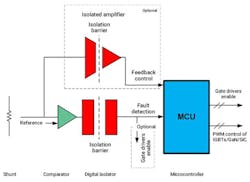

A typical fault-detection mechanism checks for overcurrent conditions using either a shunt resistor or Hall-effect sensor. Figure 2 shows a shunt-based solution that incorporates an isolated amplifier and nonisolated comparator. When the allowable current level (set by a reference signal connected to the comparator) is exceeded, the comparator signals the fault condition to the MCU. Optionally, you can use the same amplifier for feedback control.

The isolated amplifier in Figure 2 can have a 2- to 3-µs propagation delay. If that’s too slow for your design, consider using an isolated-modulator approach, which can have a propagation delay as low as 1 µs.

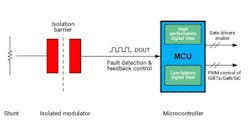

Figure 3 shows a modulator generating an isolated bitstream whose time average is proportional to the voltage across the shunt resistor. The MCU can use its internal digital filter to calculate the analog shunt voltage and take protective action when the allowable current threshold is exceeded. You can use an additional MCU digital filter running in parallel for feedback and control based on the same bitstream.

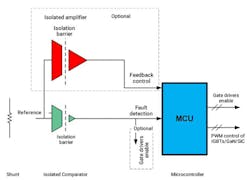

To achieve worst-case propagation delays of less than 1 µs, you can utilize a nonisolated comparator followed by a digital isolator to implement fault detection (Fig. 4). An optional isolated amplifier can be added to provide feedback control. And finally, to achieve very low propagation delays, you can use an isolated comparator such as TI's AMC23C12, which has a latency of less than 400 ns.

Figure 5 shows the device employed in a shunt-based fault-detection circuit. As in the Figure 4 example, an isolated amplifier can be incorporated for feedback control.

Isolation Fundamentals

As the previous examples illustrate, isolation is a key factor in implementing high-voltage circuits. A thorough understanding of the subject is critical for success in designing high-voltage systems for automotive and other applications. To help bring you up to speed, TI offers training videos that discuss what isolation is, describe the types of isolators, and present application examples.

An introductory video describes optical, capacitive, and inductive galvanic-isolation techniques, which prevent unwanted dc currents from flowing between two subcircuits of a system while still allowing signal and power transfer. The video explains why isolation is often required to enable a system to function, and how it enhances safety by preventing electrical shock and improves reliability by protecting delicate components from damage.

Another video defines basic and reinforced isolation in accordance with the VDE 08840-11 standard and discusses surge-test requirements.

Other videos describe specific applications, such as the design of a bidirectional onboard charger for EVs and HEVs. The design is based on TI’s silicon-carbide (SiC) and embedded technologies; it includes a digital controller, current and voltage sensors, and high-voltage isolation products. Yet another video describes an EV/HEV traction inverter and its required subsystems, which in turn incorporate components such as reinforced isolated gate drivers and isolated amplifiers.

Conclusion

Isolation is key for safe, reliable operation of high-voltage subsystems in EVs, HEVs, and related applications. TI has products ranging from SSRs to isolated comparators to help you implement those subsystems. In addition, the company offers full support, including training videos spanning topics ranging from isolation basics to EV traction-inverter design.

Sponsored Resources: