Members can download this article in PDF format.

A battery-management system (BMS) lies at the heart of today’s electric vehicle (EV). The BMS has the dual roles of protecting the battery against damage and maximizing the driving range available on a single charge. Semiconductors play a key role in implementing the algorithms that optimize charging and discharging cycles and detect potential battery defects that could lead to significant damage.

BMS Architecture

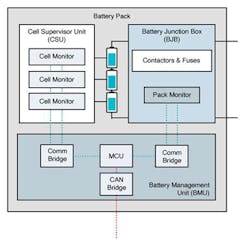

A BMS typically employs a modular distributed architecture with three major subsystems (Fig. 1): the cell supervisor unit (CSU); battery-control unit (BCU), also known as a battery-management unit (BMU); and battery junction box (BJB), also known as a battery disconnect unit (BDU).

The CSU senses the voltage and temperature for each battery cell and performs cell balancing to compensate for inconsistencies between cells. The BCU incorporates the parametric information that the CSU gathers to perform battery-pack management. The BJB has traditionally included electromechanical contactors and fuses but no electronics. However, modern intelligent BJBs are adding silicon devices to perform monitoring functions.

Chemistries and Range

Accurate battery monitoring is becoming increasingly important as automakers investigate different lithium-ion battery technologies. Nickel-manganese-cobalt (NMC) chemistry currently dominates the lithium-ion space. However, nickel and cobalt are rare and difficult to extract, making NMC batteries expensive.

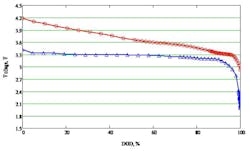

Consequently, automakers are looking at lithium-ferro-phosphate (LFP) chemistry, which lacks the energy density of NMC but costs less. In addition, LFP batteries lend themselves to longer cycle lives and are more stable than NMC batteries. LFP batteries require extremely accurate measurements, though, because they exhibit a very flat discharge characteristic (Fig. 2).

Whatever the chemistry, a key role of a BSM is accurate estimation of remaining battery charge, and therefore driving range. Vendors will specify a nominal capacity, but that value changes over time in response to aging, temperature, number of charge/discharge cycles, and depth-of-discharge patterns. Furthermore, an accurate assessment of battery health can alert a driver to have an aging battery replaced before an explicit cell failure occurs.

Wired or Wireless?

The typical BMS incorporates a wired architecture—an effective way of achieving Automotive Safety Integrity Level (ASIL) D in accordance with the ISO-26262 standard because functional-safety capabilities can be built into the daisy-chained wired communications protocol. The wired architecture has drawbacks, though. Cable harnesses add weight and can fail, leading to expensive warranty repairs.

The wireless BMS alternative offers several advantages, including improved production efficiency and reduced size and weight. In addition, the wireless architecture inherently provides isolation, minimizing the need for transformers or capacitors.

On that front, Texas Instruments offers an automotive-qualified CC2662R-Q1 SimpleLink wireless microcontroller (MCU) for wireless BMS applications. It includes a 48-MHz Arm Cortex-M4 processor and can run a 2.4-GHz proprietary wireless BMS protocol.

CSU and BCU Details

The CSU interacts directly with the battery-pack cells, accessing the cells via a wire harness or wireless link. It gathers diagnostic data to enable state-of-health and state-of-charge status, synchronizing the measurements at high data rates to provide the most accurate estimations.

With the LFP battery becoming more popular, its flat discharge curve compared to that of the NMC battery requires even more accurate cell voltage measurements to determine the usable mileage of an EV. The TI BQ79718-Q1 stackable battery monitor and cell balancer provides accurate measurements for 18 cells in series, achieving ±1-mV cell-voltage-measurement accuracy. The device, combined with the BQ79731-Q1 battery monitor, also supports synchronized voltage and current measurements.

The BCU processes acquired data from the CSU to determine how to optimally charge and discharge the battery in accordance with the condition of each battery cell. Continuous monitoring of the battery conditions enables calculations of state of charge, state of power, and state of health. It transmits the information it gathers to the automobile vehicle control unit through a controller area network (CAN) communication link.

Intelligent BJB

The BCU has traditionally controlled protection functions, signaling the BJB to disconnect its contactors in the event of a crash or short circuit. Now, however, BJBs are taking on some of the functions of the BCU. These intelligent BJBs include an electronic battery-pack monitor, which measures battery voltages and currents as well as temperature, passing that information to the BCU’s microcontroller over a twisted-pair link. This approach helps eliminate long wires and cable harnesses, thereby minimizing noise to improve measurement accuracy.

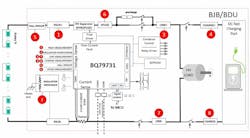

Figure 3 shows an intelligent BJB incorporating the BQ79731 battery-pack monitor, which can measure voltages across fuses and contactors. The device has two integrated current-sense paths supporting a low-side shunt resistor. A coulomb-counting function improves the accuracy of state-of-charge calculations. Fifteen GPIOs/auxiliary inputs can be used for high-voltage and thermistor measurements and to drive relays.

Isolation

High-voltage systems such as electric-vehicle battery packs often require isolation when measuring parameters such as insulation resistance. TI offers a line of solid-state relays that can provide such isolation, including the TPSI2140-Q1 isolated switch, which has integrated FETs, and the TPSI3050-Q1 isolated driver, which can control external FETs.

The TPSI3050-Q1 and TPSI2140-Q1 integrate power and signal transfer across a single isolation barrier, making a secondary bias supply unnecessary, thereby enabling a compact solution size. These products offer a superior alternative to electromagnetic relays and photorelays. They have moving parts subject to mechanical failure and internal LEDs subject to deterioration, respectively.

Conclusion

Sophisticated BMSs that reliably measure a battery pack’s state of charge—and hence remaining driving range—are keys to eliminating range anxiety and giving drivers full confidence in their electric vehicles. Texas Instruments offers products ranging from isolated switches to wireless microcontrollers and battery-monitoring ICs to help you design effective high-voltage systems as BMS architectures and battery chemistries evolve.