Space-Saving Active EMI Filters Mitigate Common-Mode Emissions

Members can download this article in PDF format.

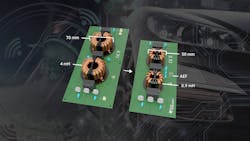

Since power density is a primary measuring stick for high-power applications in challenging form factors, Texas Instruments’ development of standalone active electromagnetic-interference (EMI) filter ICs that reduce the size of chokes by 50%, trim costs, and help designers meet stringent EMI requirements indeed raises eyebrows.

Granted, that’s a significant claim. The singular question, then, is whether TI can back it up?

The answer is yes. Comité International Spécial des Perturbations Radioélectriques (CISPR) standards are the global benchmark for limiting EMI in electrical and electronic devices. The TI active EMI filter (AEF) ICs sense, process, and mitigate EMI by as much as 30 dB, helping engineers meet CISPR 11, CISPR 32, and CISPR 25 EMI requirements.

The AEF ICs also meet IEC 61000-4-5 surge immunity requirements. This minimizes the need for external protection components, such as transient-voltage-suppression (TVS) diodes.

TI’s family of AEF ICs consists of the TPSF12C1 and TPSF12C3 for single- and three-phase commercial applications, and TPSF12C1-Q1 and TPSF12C3-Q1 for automotive applications. These parts help detect, process, and reduce EMI in a broad range of ac-dc power supplies, on-board chargers, servers, UPS, and other similar systems dominated by common-mode noise.

How Do They Operate?

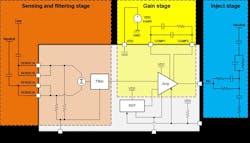

Active EMI filters work by detecting the voltage at the input and generating an appropriate cancellation signal. This effectively removes the EMI current causing the disturbance.

The AEF integrated circuits in TI’s power-supply filter portfolio make it possible to achieve up to 30 dB of additional EMI attenuation at frequencies between 100 kHz and 3 MHz in single- and three-phase ac power systems. As a result, the inductance value of chokes in common-mode filters drops by as much as 80%.

A common-mode (CM) choke is an electrical filter that blocks high-frequency noise common to two or more data or power lines while allowing the desired dc or low-frequency signal to pass. CM filters for high-density applications often limit the total Y-capacitance.

Y-capacitors are designed to filter out common-mode noise. These capacitors are related to touch-current safety requirements—if they short-circuit, they create a risk of shock to the user. Thus, the need arises for large-sized CM chokes, resulting in a passive filter design with bulky, heavy, and expensive CM chokes that dominate the overall filter size.

For automotive on-board chargers and server power supplies, it’s important to reduce the volume of the EMI filter components so that the solution can fit into demanding form factors. For example, passive EMI filters, which are comprised of inductors and capacitors, can be one of the biggest volumetric parts in automotive power electronics systems. Space-constrained applications can use active power-supply filter ICs to reduce the size of magnetic components and the overall filter.

Unlike a passive filter, an AEF circuit uses active devices and control to sense the residual voltage or current disturbance. It injects an opposing signal that directly negates that noise disturbance (Fig. 1).

The advantages of using an AEF in a circuit include a simpler filter structure with a wide operating frequency range and high stability, as well as reduced CM choke size with lower volume, weight, and cost. The shift of next-generation power electronics toward higher densities, improved performance, reduced weight, and lower cost necessitates this approach to EMI filter design.

Power electronics designers can take advantage of the AEF integrated into TI’s automotive controller, the LM25149-Q1, to deal with EMI challenges in automotive environments. It also improves power density and helps lower the cost of their power solutions.

Packaging and Availability

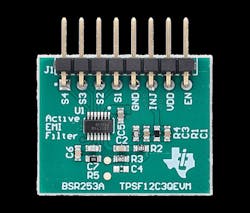

Offered in a SOT-23 14-pin package, the IC integrates compensation and protection circuitry to further reduce the implementation complexity and minimize the number of external components.

TI expects all devices to be available in volume production in the second quarter of 2023 and plans to release additional standalone AEF ICs later in the year. Pricing starts at US$0.78 in 1,000-unit quantities. The TPSF12C1QEVM and TPSF12C3QEVM evaluation modules (Fig. 2) are available on TI.com (US$75).

Conclusion

It’s challenging to achieve a compact and efficient design for the EMI filter stage in high-density switching regulators, particularly for automotive and industrial applications where solution size and cost are such priorities.

As noted, the benefits using an active EMI filter include a simpler filter structure with a wide operating frequency range and high stability margins; a reduced CM choke size with lower volume, weight, and cost; and no additional magnetic components (the AEF circuit only uses Y-rated sense and injection capacitors). Furthermore, the standalone IC implementation offers flexibility in terms of placement near the filter components.