Applying Ceramic Tech to Achieve High Power Density (Part 1)

This article is part of the Power Management Series: Delving Into Power Density. This article is also part of the TechXchange: Charging Capacitors.

Members can download this article in PDF format.

What you'll learn:

- Comparison of Class I and Class II MLCCs.

- The importance of equivalent series resistance.

- Why Class I caps are the choice when meeting power-density requirements.

Two primary characteristics of a capacitor are its energy density and power density. In Part 1 of this two-part series, we will focus on power density. Capacitor power density can be calculated as a quantity per unit volume or per unit mass.

We’ll also look at the characteristics and technology of Class I versus Class II multilayer ceramic capacitors (MLCCs) to determine which class will have the best performance for high-power-density applications. Some key applications can include snubbers, dc-link, and resonant converters.

Semiconductor devices that use a switching technology are the prime drivers for increasing efficiency and power density because they significantly contribute toward lower dynamic and static losses in power systems. However, designers are finding it more expensive and challenging to achieve incremental improvements. Capacitors are becoming better recognized for having the potential to improve efficiency, leading to better power density.

Capacitors and Efficiency in a System Design

In power design, there are three key applications in which capacitors positively impact the efficiency of an electronic system. In each area, the capacitor will have a bit of a different requirement:

- In a dc-link, high voltages, high temperatures, high frequencies, and high ripple current will be essential.

- With a snubber design, the requirement will be high dv/dt, high voltage, high ripple current, high temperature, and low inductance.

- A resonant power converter will need to satisfy high ripple currents, wide operating voltage ranges, as well as capacitance stability maintained over temperature plus dc and ac voltages.

When we combine these above requirements, the design will necessitate a capacitor with very low loss and maintain high ripple-current handling. It must also have the ability to withstand high voltages and handle higher operating temperatures while maintaining a stable capacitance and high mechanical stability. The next section examines capacitor packages that can deliver the above requirements.

Class I MLCC Capacitors

Class I MLCCs, including C0G, NPO and U2J, are at the top of the list to readily meet the above requirements.8 These capacitor types have been shown to be ultra-stable with high temperature stability, low loss, and a high ripple-current capability. These features make them a designer’s first choice for high-power-density applications.

Capacitor dielectrics are typically classified by their capacitance stability over temperature. Class I C0G, NPO, and U2J exhibit the best temperature stable dielectrics. However, this class of capacitor has the lowest dielectric constant (K). A higher volume is necessary to achieve the same capacitance as Class II MLCC types.

Class I dielectrics are much more stable than Class II. As a result, they’re an excellent option for resonant applications like LLC resonant converters and wireless-charging circuits.

For example, C0G has a very small capacitance shift of 30 ppm/°C, or 0.3% at 125oC. U2J has 750 ppm/°C or 7.5% at 125oC and is predictable and linear. Both C0G and U2J exhibit a negligible capacitance change versus dc bias and virtually no change versus time—in essence, exceptionally low aging.

Equivalent Series Resistance

Equivalent series resistance (ESR) is quite a vital characteristic that must be considered for capacitors in power applications due to i2R losses.8 Barium titanate (BaTiO3) is a ferroelectric material that can create domain regions within the capacitor dielectric and domain wall heating with a higher ESR as compared to Class I dielectrics.

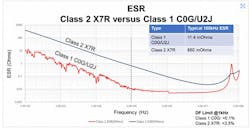

It’s very common for Class II MLCCs to have an ESR up to two orders of magnitude higher than Class I MLCCs. Figure 1 shows an example of ESR for Class I C0G/U2J MLCCs and Class II X7R.

Class I vs. Class II MLCC Construction

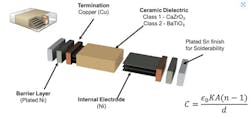

MLCC capacitors have some excellent properties that prove to be ideal for resonant, snubber, and dc-link applications. They’re built with alternating layers of ceramic dielectric and metal electrodes, which are primarily fabricated using base metal electrodes (BMEs).

MLCC devices will usually have a nickel electrode and a calcium-zirconate (CaZrO3) dielectric for Class I or BaTiO3 dielectric for Class II (Fig. 2).1

How Critical is ESR in Capacitors?

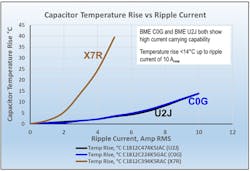

I2R losses in capacitors can lead to unnecessary and excessive heating, especially when coupled with a high ac current in power designs. Figure 3 shows how an X7R capacitor can increase its temperature by as much as 40oC, even with only 5 A rms.

However, U2J and COG dielectric capacitors will have a self-temperature increase of about 15oC at 10 A rms.

Class I Capacitor Technology Excels in High-Power-Density Apps

Class I BME dielectric-based MLCCs, e.g., U2J and COG, are the best choice in applications requiring high power density. These types of capacitors have a predictable performance and circuit designers can rely on getting an excellent tolerance.

Summary

This article discussed the power-density characteristics of Class I and II multilayer ceramic capacitors, including efficiency in electronic system design, equivalent series resistance, and Class I vs. Class II MLCC construction. Part 2 will take a closer look at energy density.

Read more articles in the Power Management Series: Delving Into Power Density. Also, read more articles in the TechXchange: Charging Capacitors.

References

1. “What Ceramic Technologies are Best for High Power Density Applications? | Part 1,” Kemet.

2. “What Ceramic Technologies are Best for High Power Density Applications? | Part 2,” Kemet.

3. “Excellent energy density and power density achieved in K0.5Na0.5NbO3-based ceramics with high optical transparency,” ScienceDirect.

4. “Electrical characteristics of high energy density multilayer ceramic capacitor for pulse power application,” IEEE Xplore.

5. “High energy storage density and power density achieved simultaneously in NaNbO3-based lead-free ceramics via antiferroelectricity enhancement,” Journal of Materiomics, 2021.

6. “Remarkably enhanced dielectric stability and energy storage properties in BNT–BST relaxor ceramics by A-site defect engineering for pulsed power applications,” Journal of Advanced Ceramics, 2022.

7. “Progress and perspectives in dielectric energy storage ceramics,” Journal of Advanced Ceramics, 2021.

8. “Here’s what makes MLCC Dielectrics different,” Kemet 2019.

About the Author

Steve Taranovich

Freelance Technical Writer, Phoenix Information Communication LLC

Steve is a contributing editor to Electronic Design.

Author of the non-fiction “Guardians of the Right Stuff,” a true story of the Apollo program as told by NASA and Grumman Corp. engineers, an astronaut, and technicians.

Experienced Editor-In-Chief of EETimes/Planet Analog and Senior Technical Editor at EDN running the Analog and Power Management Design Centers from 2012 to 2019.

A demonstrated history in electronic circuit design and applications for 40 years, and nine years of technical writing and editing in industry. Skilled in Analog Electronics, Space-related Electronics, Audio, RF & Communications, Power Management, Electrical Engineering, and Integrated Circuits (IC).

1972 to 1988 worked as a circuit design engineer in audio (8 years) and microwave (8 years). Then was Corporate Account Manager/applications engineer for Burr-Brown from 1988 to 2000 when TI purchased Burr-Brown. Worked for TI from 2000 to 2011.

Strong media and communication professional with a BEEE from NYU Engineering in 1972 and an MSEE from Polytechnic University in 1989. Senior Lifetime member of IEEE. Former IEEE Long Island, NY Director of Educational Activities. Eta Kappa Nu EE honor society member since 1970.