Members can download this article in PDF format.

Semiconductors are becoming increasingly important in their contribution to vehicular efficiency and safety. They play a significant role in state-of-the-art radar and camera sensors, security, data management, motor control, battery-management systems (BMS), efficiency, as well as environmental comfort. Today, all of this—and more—is integrated and controlled by a high-performance centralized computing system.

Because there are many angles and tangential vectors to this technology, covering them all would require pages and pages of text. Therefore, this article will focus on two of the more critical components of electric-vehicle (EV) technology: intelligent BMS, and safety in the vehicle’s battery disconnect system, particularly the chips that enable it.

Failure isn’t an Option

The battery disconnect system is one of, if not the, most important components when it comes to EV safety. Above all, the consumer must be protected from any type of electrical fault. Newer vehicles have voltages as high as 800 V DC with hundreds of amps of current, so there can be no margin for error. Therefore, the chips and devices that control it must be at the edge of the technology envelope.

At the top of the list is a failsafe disconnect system. To achieve this, next-generation BMS incorporate an advanced microcontroller unit (MCU) with a bidirectional communication link. Its claim to fame is the capability to receive sensor data and forward it to the vehicle network and back again.

Advanced MCUs for this application include a multicore design and integrated computation units that can handle complex algorithms. They also run at much higher frequencies (up to 1 GHz vs. typical 100 MHz) and can manage the increased number of input/output (I/O) requests, along with the higher voltage and currents found in advanced EVs.

Finally, from a safety standpoint, MCUs such as the TI AM263P4-Q1 MCU meet the above requirements. They also raise the bar for safety.

One example is built-in hardware to bolster security and support open and standardized automotive software architectures, such as the Automotive Open System Architecture (AUTOSAR). There’s more, but space limits what we can discuss.

The Disconnect

While many components make up the BMS, of late, two critical elements—pyro-fuses and contactors—face some design challenges. With higher voltages and currents, new designs are required to meet the tougher margins of safety and do so with increasing efficiency.

The pyro-fuse driver is responsible for disconnecting the battery from the rest of the system. It’s the preferred device for late-generation EVs because it has higher reliability and better meets the failsafe deployment requirement. Melting fuses are still used, but less frequently these days, as supply power systems ramp up voltages and currents.

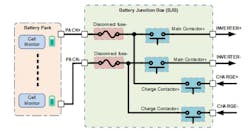

Unlike melting fuses, pyro-fuses must be triggered. Typically, they’re triggered by a drive signal from either the airbag squib driver or other discrete sensing circuit in the event of an anomaly such as an accident (Fig. 1).

However, with higher system power, designing drivers for pyro-fuses becomes more complex, requiring faster, more reliable reaction times. This challenge calls for a new design in pyro-fuse response.

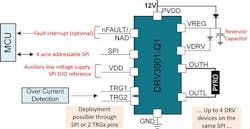

Enter the DR3901-Q1 pyro-fuse driver. This driver integrates a range of advanced features to ensure five-nines reliability. First, it has a fast response time. This quick response is achievable because the driver implements a direct 2-pin hardware interface that can bypass the Serial Peripheral Interface (SPI). Furthermore, the DRV3901-Q1 can be paired with a voltage, current, and resistance (VIR) sensor for even faster activation.

It also has the ability to monitor the available backup power via a reservoir capacitor. In this scenario, the capacitor acts as a backup power source for the pyro-fuse system in case the main supply from the battery is no longer available. By periodically checking the discharge voltage of this capacitor, it enables the DRV3901-Q1 driver and the MCU to detect a failure of this backup power supply before it occurs.

Five-Nines Reliability

On the flip side, preventing a misfire is as important as firing when required. A misfire can render the vehicle inoperative, so it’s important that the fuse is as reliable in protecting against misfiring as it is with firing.

To prevent misfires, this driver integrates several advanced features, including a safety diagnostics routine and an integrated safety check to validate operability. This is achieved with integrated functions, including separate high- and low-side drivers, redundant pins for the direct hardware firing, and cyclic redundancy checks (CRCs) on the SPI (Fig. 2). All of this ensures a fast and reliable power cutoff function.

The Efficiency Element

With EVs using batteries as the only power source, it’s critical to view all elements with an eye toward power efficiency. TI addresses that scenario with the intelligent DRV3946-Q1 high-power contactor driver.

This single-solution driver is designed to replace the more complex economizer products. Both are intended to reduce the energy consumption. However, the DRV3946 handles the on/off/steady-state function in a much more efficient and safe manner.

Increasing efficiency comes from the use of a programmable peak-and-hold circuit. This circuit intelligently applies more current during startup (2.5 A). Once the connection is made, it reduces the current to a hold value (1 A). Such programmability offers a flexible, robust, and efficient contactor function.

In the End

Clearly, improved functionality of circuits such as these could not be achieved without the remarkable advances in semiconductors. As vehicles become more complex, it falls to such progress made in semiconductors to raise the features and functions bar to improve safety, efficiency, and much more.