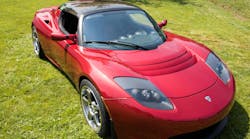

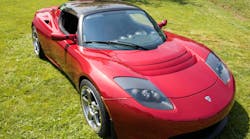

Tesla Motors used model-based design tools from The MathWorks to develop the 2008 Tesla Roadster.

Paul Lomangio, Roadster program manager and CAD/PLM technology manager at Tesla Motors, said the firm placed heavy emphasis on early stage simulation when it designed the electric sports car.

“We were on very aggressive schedules to develop a new powertrain program in approximately six months, and we didn’t have the time or the budget for ‘build and test’ to explore design alternatives,” he said.

Lomangio said that many of the engineers who worked on the electric vehicle came from Stanford University and were familiar with toolsets available at Stanford, including MATLAB. “There was no need for training on a model-based design tool.”

Using MATLAB, Tesla Motors engineers took a ‘bottom up’ approach, modeling components and then combining them. “We did systems modeling in Simulink, but to get there we started with very small kernels, validated each component, and connected components together in a hierarchical manner.”

The Tesla Motors design team used MATLAB and Simulink to model the entire vehicle and its major subsystems. Engineers combined individual models for each major system of the car, including the motor, battery, transmission, brakes, tires, power electronics, and control systems, into one full-system model, which they used to simulate and predict overall vehicle performance before building prototype vehicles.

The simulated results were then compared against road-test results from prototype vehicles to refine the full-system model. This approach shortened overall design and test processes and enabled Tesla Motors to deliver the 2008 Tesla Roadster for $145 million, a fraction of the typical vehicle program cost.