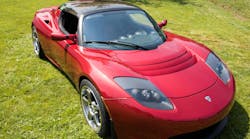

Rising fuel prices and the nation's dependency on foreign oil— as well as increasing air pollution—are spurring a quest for alternative power sources. Tesla Motors is offering one solution with its Roadster electric car. Powered by rechargeable lithium-ion ( Li-ion) batteries, this sports car has a range up to 250 miles on one battery charge, depending on driving conditions (Fig. 1). And while it's cruising, it doesn't release any emissions at all.

The weights of the body and batteries alike are key design factors in electric cars. Tesla based its chassis design on the Lotus Motors Elise, which is similar in size to the Roadster. Roadster designers had a choice between aluminum, fiberglass, or carbon fiber for body panels. They opted for carbon fiber, whereas the Elise's body is fiberglass. Carbon fiber is more expensive, but it saves about 200 lb.

The next decision was to select the optimum battery among lead-acid, nickel-metal hydride, and Li-ion technologies. Li-ion won because, for the same power, it's lighter and has greater energy density than the others.

Another design decision was the choice of motor, either ac or dc. Tesla designed the three-phase, four-pole ac induction motor, rated at 248 HP with a nearly flat torque curve from 0 to 13,500 rpm. The motor provides direct drive to the car's rear wheels. It can provide negative torque, otherwise known as regenerative braking, to enhance range.

TWO-SPEED TRANSMISSION

A unique two-speed electrically actuated manual transmission provides optimum efficiency. The gear shift has an electromechanical transmission lock (park position), and there's no clutch.

This transmission maximizes acceleration while also allowing a reasonably high top speed. First gear gets you from zero to 60 in about 4 seconds, while second gear can take you to over 130 mph.

The Roadster's gearing works together with the gear shift and internal power electronics to provide familiar driving behavior. First gear has strong regenerative braking that recharges the battery during deceleration and feels like an engine braking in low gear. Second gear has less regenerative braking and feels like third or fourth gear. The Roadster needs only two gears because the motor delivers high torque over a much wider range of rpms than a gasoline engine.

The Power Electronics Module (PEM) is an air-cooled, computer-controlled system for the motor (Fig. 2). It is an integrated power inverter and high-rate charging system. It also is an inverter, charger, and motor controller. This configuration lets regenerative braking flow through the charging system into the PEM, which employs an insulated gate bipolar transistor (IGBT) output stage.

BATTERY POWER

The Energy Storage System (ESS) contains Li-ion batteries in a durable, tamper-resistant enclosure behind the seats, very close to the center of the car. It provides a mechanical structure to mount the batteries, electrical interconnection between the cells, interconnection to the power electronics unit, a network of microprocessors for maintaining charge balance and temperature monitoring, and a cooling system. Its independent safety system isolates high voltage outside the enclosure under a variety of detectable safety situations.

To keep temperatures under control, the electronically controlled liquid cooling system uses a secondary loop in the cabin air conditioning system to provide chilled coolant circulated throughout the ESS. A resistive heater can heat the batteries in extreme cold conditions.

Battery packs consist of 11 identical groups of 621 lithium-ion cells (called sheets) connected in series and parallel. Each cell is 18 mm in diameter and 650 mm long with a nominal 3.6 V and a 2.2-A/hr rating. Each sheet produces 32.4 V (nominal). One sheet supplies voltage for the car's accessories, such as lights and power windows. The remaining 10 sheets provide 324 V for the motor.

The Roadster comes with the Electric Vehicle Service Equipment (EVSE), a home-based charging system. It operates from a 220-V ac power line that lets it recharge a battery in 3.5 hours. During charging, the maximum input power is 240 V ac at 70 A, 45 to 65 Hz, and about 17 kW. Projected battery life is more than 100,000 miles and five years. Battery replacement must be performed at a Tesla Service Center at a cost yet to be determined, as battery prices continue to drop.

The Battery Safety Monitoring system checks battery temperature, current, and voltage, as well as vehicle factors, such as high acceleration (indicating a crash), smoke, and temperature. The monitor includes overcharging protection, three layers of fuses, and sensors that trigger the batteries to disconnect in the case of high temperatures, sudden impact, or rollover. It disconnects the high voltage if any of these factors are out of range.

Determining energy efficiency requires a computation of well-to-wheel efficiency from the source of the fuel (usually the oil well or natural gas) to the wheels. Tesla points out that the Honda Civic CX is the most efficient traditional gasoline car with an efficiency of 0.52 km/MJ. The hybrid Toyota Prius has an energy efficiency of 0.56km/MJ. A PEM fuel-cell car has a calculated efficiency of 0.77km/MJ, though this technology is in its infancy and could conceivably increase over time. In contrast, the Roadster has a computed efficiency of 1.14 km/MJ.