Contact Design Achieves High Current Density with Low Insertion Force

A power contact technology developed by Tribotek of Burlington, Mass., increases the current-carrying capacity achievable in power distribution systems at costs said to be competitive with existing power interconnect solutions. Tribotek’s LowR contact design decouples the electrical and mechanical functions of the connector. Simultaneously, it uses pure copper conductors with many parallel points of contact to achieve a low (milliohm) contact resistance capable of high current density.

The technology targets a wide range of potential applications, including telecom, data storage and computer systems. Tribotek’s contact design also may be applied in industrial, ATE, military and other equipment designs.

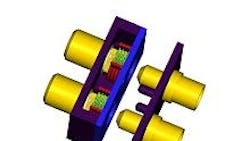

Tribotek’s contact system combines a conventional pin with a woven socket in which gold-plated copper wire conductors are woven with an engineering fiber (Fig. 1). Kevlar is typically used for the fiber, although other engineered fibers may be used, depending on application requirements.

The engineered fiber is tensioned to produce the normal force between the socket and the mating pin (Fig. 2). The free ends of the copper conductors are terminated into a ferrule, and the engineered fibers are crimped into a mechanical spring. As the mating pin is inserted into the socket, the fibers are tensioned to generate the required normal force. This design results in very low insertion forces for contact mating and minimizes contact wear without the need for lubricants.

Because Tribotek’s contact system maintains wipe across the mating surfaces, debris is cleared and oxide layers are broken, improving reliability. Because of the highly redundant contact surface, electrical contact can be maintained even in the presence of contamination from dirt and debris. The contact system also is highly tolerant of vibration and thermal cycling. Vibration tolerance has been demonstrated with resistance readings consistently in the 0.11mΩ to 0.13-mΩ range across the separable interface during 3 hrs of vibration testing at 3.1 G ‘RMS’.

Current ratings depend on contact size, but may be as high as 700 A for the largest contact, a size #4/0 (0.5-in. diameter) pin. For the smallest-sized pin (0.040-in. diameter) available, the rating is 70 A. These ratings assume one mated pair terminated to bus bars. In addition to bus bar terminations, the contacts are available with pc-board and cable-type terminations.

Connector pricing is application specific and is influenced by the selected terminations and housings. However, according to the vendor, the connectors are price competitive with other high current-density power connectors on the market.

For more information, visit www.tribotek-inc.com.