SpringSoft’s Laker custom place-and-route system

Custom IC layout is a time-consuming, painstaking task that challenges both designers and their layout tools. SpringSoft’s custom IC layout system was initially introduced to address the problem of achieving acceptable quality of results and run times. Employing both rule-driven and schematic-driven layout styles, Laker makes it easier to avoid layout-versus-schematic (LVS) errors even as it reduces the time for custom layout.

In the latest iteration of Laker, SpringSoft has added support for the OpenAccess database and application-programming interface (API) from Si2. From a purely business perspective, there are a few advantages to any tool having support for OpenAccess. “Designers are trying to get away from dependency on tools from a single vendor,” says Duncan McDonald, SpringSoft’s director of product marketing for Laker. OpenAccess enables the creation of parallel flows without proprietary lock-in.

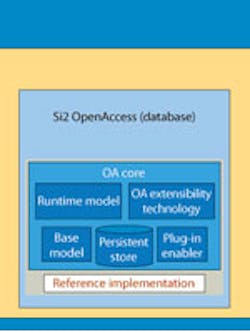

The other compelling business driver behind the use of OpenAccess is interoperability (see the figure). “OpenAccess is the basis for building interoperability into the flow so you can have best-in-class tools at every stage,” says McDonald. It enables designers to incorporate tools from other vendors who support OpenAccess or to use in-house tools crafted for particular purposes.

Through OpenAccess, Laker supports the IPL Alliance’s interoperable process design-kit (PDK) libraries. This effort seeks to establish an interoperable eco-system in custom design. “We’ve done extensive interoperability testing with Magma, Ciranova, and Synopsys and their OpenAccess-enabled tools to ensure that we can exchange data,” says McDonald.

As to the details of Laker’s integration with OpenAccess, SpringSoft says that Laker is the only tool in its class that supports all three of the possible interfaces with third-party tools: file exchanges, data exchanges, and a tightly coupled runtime model. The runtime model is the most sophisticated of the three, in which multiple applications can share the same memory without having to open and close the applications. “This makes the tools look like part of the same environment,” says McDonald.

Other enhancements to the Laker system include a new custom row placer and custom digital router. Both work directly in Laker with no need for the time sink of environment switching. There are also no data-translation or compatibility issues involved. Together, the placer and router are wire-length driven and work with smaller designs of 50,000 fixed-height standard/custom cells.

The tools support advanced process technologies, with 28-nm support planned by the end of 2010. They provide routing for power and ground layers for complete design support. Laker performs a hybrid approach to routing, performing first a fast gridded route. After doing design-rule checking, the tool then switches to a shape-based route that yields a DRC-clean (design rule checking) output with a high completion rate.