Rechargeable Battery is One Long Filament—and You Can Cut It as Needed

What you’ll learn:

- The unique concept of a rechargeable battery made as a thin fiber.

- How the battery is fabricated using conventional fiber-drawing techniques.

- Details of the electrical and mechanical performance of this fiber battery.

- Some of the unusual demonstration apps for this battery.

Batteries come in wide range of fully enclosed, sealed form factors and packages including cylindrical, rectangular, button, and coin, as well as custom units for specialty applications. Now, an MIT-led team has truly gone “out of the box” by developing a rechargeable Li-ion battery that’s fabricated as a continuous fiber using a standard fiber-drawing system and novel battery gels. Another key attribute is the battery can be cut anywhere along its length and still function without leakage of contents.

As tangible demonstration of the absence of limitation on length, they drew a battery filament over 140 meters long; this fiber battery had discharge capacity of about 123 mAh and discharge energy of 217 mWh. Incorporating a filament power source into the structure of end products could lower their overall weight, enable new packaging arrangements, and allow for customization of the battery’s physical size to make maximum use of available package volume and “nooks and crannies.”

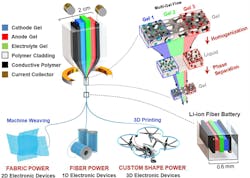

Fabrication Process

The fabrication process starts with a larger cylinder containing all of the components for simultaneous flows of multiple complex electroactive gels, particles, and polymers—all within a protective flexible cladding—and then heating it to just below its melting point. The material is drawn through a narrow opening to compress all of the parts to a fraction of their original diameter, while maintaining the original arrangement of parts (Fig. 1).

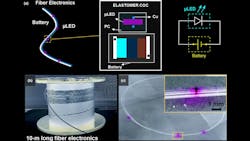

Postdoctoral student Tural Khudiyev (one of the project leaders, now an assistant professor at the National University of Singapore) noted that others have attempted to make batteries in fiber form, but those were structured with key materials on the outside of the fiber. In contrast, their approach embeds the lithium and other materials inside the fiber with a protective outside coating, thus directly making this version stable and waterproof. They also were able to embed devices such as LEDs into the drawn fiber construction (Fig. 2).

A Drone and Other Demo Apps

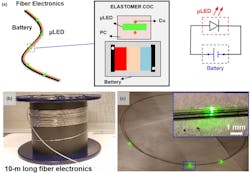

He added, “After printing, you do not need to add anything else, because everything is already inside the fiber; all the metals, all the active materials. It’s just a one-step printing. That’s a first.” The flexibility and configurability of the fiber battery offers a large degree of freedom in packaging options. For example, they wrapped a 20-meter length around a submarine drone to power it (Fig. 3).

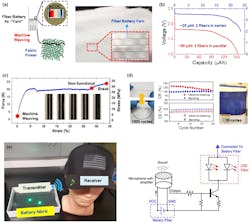

The project paper notes that the fibers, with a diameter of around 100 µm, can be used to create sophisticated and versatile battery “cloth” as it’s machine washable, flexible, usable underwater, and fire/rupture-safe. To assess the strength of the fiber—an important consideration in real-world uses—they performed static and cyclic stress/strain tensile tests.

For other dramatic demonstrations in addition to the submersible drone, they fabricated a LiFi-enabled fabric with embedded active components (Fig. 4). The battery fiber also was printed into multiple shapes, including the external casing of a flying drone, with communication from the LED of one drone to the photodiode of another drone powered by the printed battery casings.

They maintain their development is a key enabler for the emergence of innovative and perhaps unique approaches to battery-powered electronic devices. The team has already applied for a patent on the process and continues to develop further improvements in power capacity and variations on the materials used to improve efficiency. As a further benefit, the thermally drawn fiber battery is fire-resistant due to its gel electrodes and gel electrolyte, unlike other fiber batteries with liquid electrolyte that instantly catch fire.

The work is detailed in their highly readable and informative paper published in Materials Today with the intriguing title “Thermally drawn rechargeable battery fiber enables pervasive power.” While that paper is behind a paywall, they have graciously posted it at an MIT site here (but the other supplementary material and videos are not available, sorry). They also have a five-second video showing that the fiber battery can be cut, yet continues to function, and without leakage of its constituent materials.

The research was supported by the MIT MRSEC program of the National Science Foundation, the U.S. Army Research Laboratory through the Institute for Soldier Nanotechnologies, the National Science Foundation’s graduate research fellowship program, and the National Research Foundation of Korea. Due to their efforts, perhaps one day designers will specify the length of battery or how many milliamp-hours of capacity they need.