Meeting the Demand for High Power Density in Robotics

This article is part of the Power Management Series: Delving Into Power Density

Members can download this article in PDF format.

What you'll learn:

- The importance of high torque to meet power-density requirements in robotics.

- The expanding role of spindle motors.

- NASA's CADRE robotics program.

The three most critical aspects for motors used in mobile robotic applications are high efficiency, high dynamics, and high power density. And when it comes to high power density, that means high-torque mechanisms that take up minimal space.

One of the best high-power-density options for mobile robots is the dc motor with a continuous torque rating. These types of motors, especially for robotic arms, will need a high startup torque for smooth acceleration in movement.

One example of this involves the robotic drives1 that powered the NASA Mars Rover known as Opportunity, which was active on Mars from 2004 to mid-2018. High power density was a requirement for the rover.

Achieving high torque requires the addition of gearheads to the motors. Gearheads help to control a large load inertia from a comparatively small motor inertia. If gearheads aren’t used, acceleration or velocity control of the load would need the motor torque, and therefore the current, to be many times greater than the reduction ratio used in the gearhead. Going in this direction option would be costly. Thus, modular, flexible motor-gearhead combinations are the preferred solution for robotics.

Torque Rating

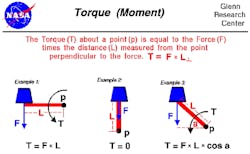

Robotic system torque is the amount of force applied in a circle, in this case the output horn of the DYNAMIXEL2 or servo.

To determine whether a DYNAMIXEL’s torque is sufficient for motion, the torque will need to be equal to or greater than the forces that the servo will need to overcome in the robotic system.3

Before designers choose their size of DYNAMIXEL, they must calculate the estimated torque requirements of their motions. A basic reference diagram is shown in the figure.

In the case of high torque for linear motion, with high force, the drive motor will need many more magnetic poles than what’s available in lower-torque motors. This high force can be achieved through proper, creative mechanical design with a high reduction ratio, while not sacrificing the benefits of the high-speed motor.

However, additional magnetic poles necessitate a more complex assembly and design. Conventional brushless dc motors that have a slotted iron core can be designed with multiple poles and, as a result, be able to provide lower speeds at higher torque.

Spindle Motors

Spindle motors4 are small, high-precision, reliable electric motors in hard drives that increase power density. This type of motor rotates the shaft/spindle upon which the platters sit; the platters are where the data is stored. The need for these high-speed spindle motors continues to escalate due to demands for high power density. Robotic systems use these types of motors because vast amounts of data can be stored within the robot body.

Another reason for the growing demand for these motors concerns the cycle time during which a machine tool needs to complete a specific operation. The faster a tool can be moved and rotated in a robotic arm, the faster it can complete its task.

Recent enhancements in spindle-motor performance are due to more powerful permanent magnetic materials, high-precision machining techniques, and improved electronic control circuitry.

Ever-Expanding Robot-System Architectures

Collaborative robots, a type of robotic automation, are designed to perform work safely alongside human workers in a shared, collaborative workspace. The collaborative robot’s role is to perform repetitive, menial tasks, along with a human worker who will complete the more complex and thought-intensive tasks. NASA’s International Space Station (ISS) is a good proving ground for collaborative robots. This kind of application demands the ultimate in high-power-density design.

NASA’s Cooperative Autonomous Distributed Robotic Explorers (CADRE) project is presently developing a complete network of shoe-box-sized mobile robots that will enable future autonomous robotic exploration on the Moon, Mars, and the universe beyond. High power density is a must here since weight is an enormous factor in space launches from Earth.

NASA has the Autonomous Pop-Up Flat Folding Explorer Robot, or “A-PUFFER,” which is a CADRE robot. Each robot will contain an onboard computer, a wireless radio for communication, and a stereo camera with multiple lenses and image sensors. These robots will sense the environment in front of them while capturing 3D imagery. A-PUFFER robots can be robot scouts that will explore as a group while collecting data in places that may be difficult to maneuver, such as craters and caves on the Moon.

Summary

Most robotics applications will demand high power density as well as high motor power density coupled with high torque capability. Robots must be lightweight with powerful motors that are capable of providing such high torque. High-power-density hard-drive spindle motors that rotate disk memory and programs can act as the robot brain and memory storage.

NASA has entered the high-power-density space (no pun intended) with its automated explorer robots. These robots can travel to distant planets and explore places where human explorers aren’t able to venture. Even higher power density in motors and power supplies will evolve as we progress into the future of expanded robotic technology and capabilities.

Read more articles in the Power Management Series: Delving Into Power Density

References

2. DYNAMIXEL

4. RobotWorx