Power Modules Shrink to Meet Space-Constrained App Demands

Download this article in PDF format.

Miniaturization is one of the electronics industry’s most impressive achievements, incorporating multiple and sometimes dozens of functions within a package small enough to fit in a shirt pocket, or even in a watch. The latter is perhaps the most impressive example, far surpassing Dick Tracy’s two-way wrist radio. However, all of these functions must be powered, and creating a way to manage that power is an increasingly difficult challenge. Fortunately, power-management modules have risen—or shrunk—to the occasion.

Miniaturization doesn’t apply only to small consumer products, but to virtually all types of commercial and industrial systems that, although larger, must still be compact. This applies even (or perhaps especially) to data centers, in which truly enormous amounts of computational and storage capability is provided by thousands of board-level (i.e., embedded) systems.

As the functions performed by these boards continue to expand, the space required to implement the power supply on each one must decrease, which is possible only with highly integrated power modules. In between these two extremes in size are the hundreds of different consumer, industrial, medical, and commercial applications in which power-management solutions compete for space with circuits that perform other functions.

Sponsored Resources:

- Himalaya: Raising the Bar for Power Modules

- Meeting the Efficiency and Power Dissipation Needs of Space-Constrained Applications

- Meeting Big Demands for Power in Small Devices

Making It Easier

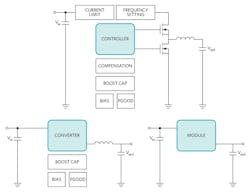

Power-supply circuits have evolved from power controllers using lots of external components to modules with higher and higher levels of integration, which continue to increase in performance and capabilities. The three general evolutionary steps of power-supply circuits (Fig. 1) show how far the industry has come. The benefits to this “it’s all inside” approach go beyond the obvious. For instance, it’s far easier for designers to concentrate on their projects rather than have to design a power supply.

1. The progression of power-supply circuit design and fabrication has been dramatic, from a controller with many external components, to an external component reduction of about 50%, to today’s power modules that have few and sometimes no external components.

This is a major benefit. To see why, consider the challenges for the designer who must create a switching power supply. He or she must evaluate many variables to produce a solution that will meet the requirements of the host product, including input and output voltage, load current, temperature, resistance, and other factors. Having done this, the designer must evaluate the various external components required and where they will be located on the board.

Each external component presents its own headaches as it must be thoroughly evaluated. Inductors can be particularly challenging—not choosing the “right” one can cause problems ranging from instability to failure in the field. There’s also the ominous presence of EMI and RFI, whose effects can be devastating and must be considered at every stage of design. This requires a level of expertise in “fields and waves” that most designers aren’t very familiar with.

Modules that Manage

The good news is that this problem has been addressed by power-management modules that exploit the advantages of new architectures, processes, and packaging technologies. They can potentially eliminate the problems mentioned above, allowing the designer to build the host product without spending time dealing with power-supply issues.

Not only do these new modules reduce the bill of materials by eliminating external components, they’re more efficient than their predecessors, and can be pin-to-pin compatible with various voltages and currents. Furthermore, they provide a roadmap for the host product line without having to abandon what’s currently being used.

Such modules essentially integrate everything from the switching power-supply controller to the power switches, inductors, and other passive components required for proper compensation and bias, with only input and output capacitors, two resistors to set the output voltage, and possibly a capacitor for soft-start.

They’re especially appealing for use in space-constrained applications due to being so much smaller than discrete solutions. The issue of EMC is eliminated because almost all external components are now integrated within the package. Therefore, the responsibility for ensuring EMC compatibility rests with the device manufacturer rather than the designer, removing a considerable amount of risk.

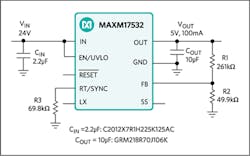

Maxim’s Himalaya family of power modules is an excellent example (Fig. 2). Nearly all components required for a complete power supply are integrated into a single package, shrinking the power-supply solution size by a factor of 2.25. The step-down dc-dc power modules have a very low profile, accommodate voltage rails from 5 to 60 V, and come in a system-in-package (SiP) or ultra-small micro-system-level IC (uSLIC) package. Some Himalaya uSLIC power modules are compliant with the CISPR 22 EMI standard as well.

2. Shown is a schematic of Maxim’s MAXM17532 4- to 42-V step-down dc-dc power module. The device integrates the controller, MOSFETs, an inductor, and compensation components.

One member of the family, the MAXM17532, is a 4- to 42-V, input step-down dc-dc power module that integrates a controller, MOSFETs, an inductor, as well as compensation components. It provides an adjustable output voltage of 0.9 to 5.5 V and supplies up to 100 mA of load current. The device is housed in a 10-pin, 2.6- × 3- ×1.5-mm package.

Summary

There’s no doubt that power management will become more challenging as subsystem and system footprints shrink while increasing in complexity. And as these systems become autonomous, they will require more processing power, which translates into greater requirements for power management as well as different and probably higher voltages.

However, coming generations of power modules will be able to accommodate these requirements. They will build on today’s capabilities, evolving toward even higher levels of integration, while simultaneously maintaining their current cool operation and small size and ability to simplify the power-supply design.

Sponsored Resources:

- Himalaya: Raising the Bar for Power Modules

- Meeting the Efficiency and Power Dissipation Needs of Space-Constrained Applications

- Meeting Big Demands for Power in Small Devices

Related Resources: