EMC test is a critical discipline in any electronic product development effort. Full compliance is the ultimate goal, but achieving it quickly and with minimal budget and schedule impact requires EMC debug efforts throughout the design process. These efforts must be combined with effective pre-compliance strategies.

Applicable equipment includes EMI receivers, amplifiers, field generators, and complete EMC test systems as well as general-purpose instruments with applicability to EMC test. Software has several roles to play, ranging from simulation tools to applications that can serve in the test lab. Augmenting instruments and systems are probes and other accessories.

According to Dean Landers, applications engineer at AR RF/Microwave Instrumentation, “We serve every aspect of the EMC test market, providing the total solution for EMC testing. Whether it’s design, pre-compliance, or full compliance, we can offer solutions through both test systems and special equipment packages to meet the needs of the customer.”

Landers said the company has recently introduced its AA Series solid-state field generators, which he described as a cost-effective solution for testing radiated susceptibility above 18 GHz (18 to 40 GHz) at test levels of up to 50 V/m at a 1-m test distance.

When asked what applications areas AR serves, Landers said the company can assist customers in meeting the requirements of relevant standards regardless of what market they are working in. “We will also ensure that the equipment provided will be acceptable across multimarket testing agencies, so the equipment can be bought once and used for multiple tests,” he added.

When asked what features customers seek in EMC test equipment, Landers cited reliability. “A test agency or laboratory needs to know for certain that their equipment, on any given day, can be placed into a test setup and work the first time, every time,” he said. “AR provides this level of quality and reliability for each product.”

Landers also pointed out, “Customers are looking for total turnkey solutions, where we not only provide the amplifiers, but the antennas, cables, racks, field probes, etc., all within a single system to test specific or multiple standards.”

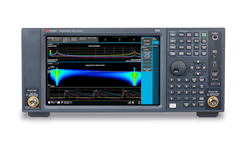

Jeff Hu, product manager at Keysight Technologies, said the company addresses full-compliance test with products such as the N9048B PXE EMI receiver, which offers 1-Hz to 44-GHz frequency coverage, and is fully compliant with CISPR 16-1-1:2019 and MIL-STD-461G. Hu explained the instrument offers a “…superior ‘Time Domain Scan’ and even faster ‘Accelerated Time DomainHu described a “Real Time Scan” troubleshooting tool, offering up to 350 MHz of bandwidth for gapless real-time signal capture and analysis. The tool allows customers to measure signals with CISPR-compliant quasi-peak, EMI average, and peak detectors simultaneously, gaining a better understanding of signals by displaying them in three windows —frequency domain, time domain, and spectrogram. Customers can also play back and view signals captured in up to 12,000 time slices (for example, 12,000 s recorded time if dwell time is 1 s), and Hu added that data can also be exported for post-processing analysis

“As customers (automotive, consumer, communications, medical, etc.) designing electronic devices race to market, they will need better, faster EMC compliance testing of new components, key subassemblies, and whole systems,” Hu said. “For EMC labs, this means greater demand for more testing and troubleshooting in less time, sometimes on short notice, as developers rush to meet looming deadlines. Day to day, the throughput rate of the main test chamber has a direct effect on two key metrics: revenue and customer satisfaction. If demand grows beyond the capacity as we’re seeing now, then the test lab can lose revenue and force customers to go elsewhere. During troubleshooting, delays in assessing failures and suggesting fixes can frustrate impatient customers.”

Hu continued, “Enhancing the lab’s success starts with a compliant EMI receiver that accelerates testing and improves troubleshooting. Equipped with Time Domain Scan, Accelerated Time Domain Scan, and Real Time Scan capabilities, the Keysight N9048B PXE EMI receiver will accelerate throughput during compliance testing and enhance the ability to catch suspect signals sooner during troubleshooting.” He added that the PXE supports many EMC software tools (such as TILE!, Nexio, and Toyo), which can leverage the PXE’s speed during automated testing. The solution also provides capabilities tuned to measurements, reporting, documentation, and more.

The MT8000A and MT8221C can help test devices and UE employing 5G NR, 4G/LTE, and legacy wireless technologies, Yasami said, adding, “In addition to ensuring compliance in accordance with FCC rule parts, Anritsu’s solutions simplify test setup and execution and provide reliable test results.”

Yasami said Anritsu solutions enable pre- and full-compliance test and certification for products including mobile phones, handsets, and portable devices. “Our platform provides the capability to ensure these products are compliant with FCC regulations, as well as a variety of other international standards and regulatory bodies.” .

According to Tobias Gross, product manager for EMI test receivers at Rohde &Gross said they’ve released a turnkey solution for automatically measuring radiated spurious emissions from 5G components in both frequency ranges FR1 and FR2. “For this solution, the R&S ELEKTRA EMC test software has been upgraded with measurement and calibration routines for 5G,” he said. “In addition, the new fast Time Domain Scan (fast TDS) for the R&S ESW high-end test receiver is one of our highlights in EMC testing. Thanks to the doubled scan bandwidth, the measurement speed is nearly twice as fast as with a conventional time-domain scan. This enables previously unattainable fast measurement times for time-consuming tests with a quasi-peak detector.” He added that fast TDS is free with the latest firmware version V1.70 for the R&S ESW.

“And last but not least, we have new EMC test solutions specifically for users in the automotive industry: the fastest CISPR-25 certification with fast TDS, a robust and compact BCI test system, and R&S AdVISE version 5, which keeps a close eye even on vibrating display elements during EMS tests,” he said.

According to Gross, a key customer requirement is for time-saving measuring routines. “That is why we have developed the fast TDS,” he said. “In addition, we have a new option for accelerating product tests on microwave ovens. Typically, test engineers use the log AV method according to standard CISPR 11. With the latest revision of the standard, the new method Multi CISPR APD is applicable as an alternative. This method not only reduces the overall testing time significantly, but also enables a detailed insight in the emission’s characteristics.”

Gross added that the R&S ESW-K58 Multi CISPR APD measurement option for the R&S ESW test receiver simultaneously displays the signal amplitude probability distribution (APD) of up to 67 channels within a specified timeframe. “The option offers numerous analysis and display features, including a 3D view,” he said. “When the method is used in line with the standard for signals with 1 MHz bandwidth, up to 20 channels can be measured simultaneously. APD analysis precisely shows the effects of interference on digitally modulated wireless signals (WLAN, cellular or Bluetooth), and in the future it will also be applied to other product standards.”

Gauss Instruments provides products for full- and pre-compliance EMI testing as well as radiocommunication measurements and 5G measurements, according to Dr. Stephan Braun, CTO. For example, the company offers EMI64k automation software and the TDEMI ULTRA, which enable automated communication and EMI measurements with 685-MHz real-time bandwidth and real-time scanning between DC and 40 GHz (expandable with external mixers in the THz range).

“We serve automotive, industrial, consumer, communication, medical, avionic and military testing,” Braun said. The products cover the CISPR 16-1-1, MIL 461, and DO 160 standards as well as ANSI, FCC, and many other national and international standards.

“With the introduction of the real-time FFT-based receiver in CISPR, ANSI, and MIL461G, customers are looking at solutions that fulfill these standards with large real-time bandwidth,” said Braun, adding that they also ask for proper automation to enjoy the benefits of the new technology. He added that the company sees more combined equipment like household appliances that need to be tested in accordance with CISPR 14 in combination with Wi-Fi modules that need to be tested for EMC and in accordance with communication standards.

Davis commented on features customers are looking for. “Today’s savvy EMC customers are looking for a company they can depend on—one who has been there in the past and will be there in the future,” he said. “They want a solid warranty (five years on SSPA systems), with excellent customer service. They want a provider who does not rest on accomplishments made in the past. They want a supplier who has a pedigree of high-power products used in the harshest military environments, who can take this knowledge and bring it to their commercial products.”

Herman vanEijkelenburg, director of marketing at Pacific Power, pointed out they just introduced a line of fully-complaint EMC power-line emissions and immunity test systems for harmonics and flicker, to test for compliance to IEC 61000-3 and IEC 61000-4 test standards. “This product compliance is mandatory to place any grid-connected product on the EU market.”.

Herman explained, “Pacific Power ECTS2 systems range in power levels from 500 VA to 90,000 VA, and are available with either single-phase mode or single-, split-, and three-phase modes.” He added that the systems address power integrity and IEC compliance testing of AC-powered products intended for export to EU countries at both the design stage and for full compliance testing to applicable IEC standards.

“These EMC power compliance test systems cover the entire spectrum of AC-powered and grid-connected products including PV inverters and electric-vehicle chargers both on-board or charging-infrastructure-related,” he said. “Also covered are DC voltage-dips test requirements applicable to automotive products. These systems are typically used by independent test labs to test customer products or by in-house labs at larger companies.”

Simulation for EMI/EMC

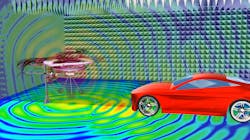

Mologni said that companies can use Ansys tools to meet stringent regulatory standards fast and economically. “Engineers can rely on the unmatched accuracy, speed, and capacity of Ansys electromagnetic 3D and 2.5D field solvers and also dynamically link these solvers to circuit- and system-level tools to predict EMI/EMC performance of electronic devices,” he said. “Assessing the overall performance of these designs through a comprehensive analysis leads to interference-free products. Automatic and customizable EMI design-rule checks of printed circuit boards in Ansys prior to running simulations save time and cost.”

When asked about applications, Mologni said Ansys tools mitigate engineering problems across different verticals including automotive, industrial, consumer, communications, and medical. Mologni added that for electronic and wireless devices, Ansys tools model radiated and conducted emissions, susceptibility, crosstalk, electrostatic discharge, electric fast transients (EFT), and lightning-strike effects. In addition, they can model high-intensity fields (HIRF), radiation hazards (RADHAZ), electromagnetic environmental effects (EEE), electromagnetic pulse (EMP), shielding effectiveness, and other EMC aspects.

“Engineers can use Ansys tools to address the following regulatory standards: electromagnetic pulse (EMP), bulk current injection (ISO 11452-4), conducted emissions locally grounded (CISPR25) and remotely grounded (CISPR2), radiated emissions (CISPR25), electrostatic discharge (IEC 61000-4-2), and radiation hazard (MIL-STD-461-C),” he said.

From spectrum analyzers to TEM cells

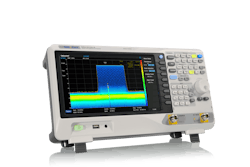

Siglent recently announced SSA3000X-R Series real-time spectrum analyzers. “The addition of real-time acquisition is a real benefit for near-field probing applications because it can decrease the time spent searching for elusive unintentional radiation sources, as well as provide very fast conducted emissions troubleshooting,” Chonko said. “With the optional 40-MHz real-time bandwidth upgrade, you can basically capture the full 35 MHz of bandwidth required by the FCC for conducted emissions in one acquisition.”

EMC test solutions are also available from distributors. For example, Newark offers complete EMC pre-compliance testing solutions, including software, spectrum analyzers, accessories, and probes for ease of use and performance to support customer needs, according to Maureen Lipps, product manager, Test & Tools. She cited as an example Newark’s recently launched Keysight N9000B-503 spectrum analyzer used with N6141C/2TP EMI software.

“Keysight’s EMI measurement application on X-Series signal analyzers allows engineers to perform pre-compliance measurements and diagnostic evaluation of their designs,” she said. “In addition, electronics makers can find and fix problems before they enter the test chamber with the N6141C measurement application on the N9000B CXA signal analyzer with multitouch UI. EMC pre-compliance capabilities include built-in CISPR- and MIL-STD-compliant bandwidths, detectors, and band presets; automated testing to regulatory limit lines with user-selected margins; amplitude correction (for antennas, LISNs, cables, and preamps); and built-in report generation.”

Lipps said Newark also offers the Tektronix RSA306B PC-based spectrum analyzer with SignalVu-PC software used with the EMCVu plug-in. “EMCVu lets designers quickly identify areas of concern to streamline testing and debugging activities,” she said. “In addition, engineers can quickly analyze suspect frequencies in more detail using a near-field probe to find the source of emission.”

A third EMC test product from Newark, Beehive Electronics 101A EMC probe sets are designed for identifying and fixing EMC problems. “The 100A, 100B, and 100C are loop probes and are sensitive to magnetic fields” Lipps said. “The 100D is a stub probe and is sensitive to electric fields. The loop probes have integrated electrostatic shields, providing isolation from common-mode signals. As a result, these probes deliver excellent repeatability. The different loop sizes allow the user to select the optimum probe for a given frequency, providing the optimum sensitivity and spatial resolution.”

Saelig Co. Inc. also offers EMC test equipment from a variety of manufacturers, including spectrum analyzers from Aaronia, Aim-TTi, Rigol, Siglent, and Triarchy; fieldmeters and probes from EMC Test Design LLC; shielded enclosures from Ramsey Electronics; probes, amplifiers, LISNs, and TEM cells from Tekbox; radiation measurement systems from MegiQ; and EMI test enclosures from Select Fabricators. Applications include near-field probing for EMC precompliance test1 and immunity testing using a TEM cell2.

As this article was being prepared for publication, organizers of the 2020 IEEE EMC + SIPI Symposium were still planning to hold the live event July 27-31 in Reno. Commenting on the issue, Landers at AR RF/Microwave Instrumentation said, “We plan on attending and will be showcasing our AA Series and other test systems, emcware 5.0, and a full chamber setup from our partner Comtest.”

Anritsu plans to highlight the Radio Communication Test Station 8000A and Radio Communication Analyzer MT8821C. “These solutions enable a range of regulatory and compliance testing, including EMC certification for FCC, ISED, and EU RED, on 5G NR devices,” said Yasami.

Gauss plans to demonstrate its TDEMI ULTRA and its automation software EMI64k, according to Braun. Hu at Keysight said the company plans to highlight its N9048B PXE EMI receiver with its Time Domain Scan/Accelerated Time Domain Scan and Real Time Scan capabilities. Gross at Rohde & Schwarz said the company plans to highlight products including R&S ELEKTRA, the fast TDS function for the R&S ESW, R&S AdVISE v5 with optical character recognition (OCR) for text and numbers as well as image stabilization, the R&S ESW-K58 Multi CISPR APD measurement option for the R&S ESW test receiver, and the R&S FPL1-K54 EMI measurement option for the R&S FPL1000 spectrum analyzer.

Features and challenges

Several contributors to this report elaborated on challenges of EMC test and features that can help engineers meet those challenges. “Many companies are trying to overcome the EMC hurdle without a deep understanding of the physical issues involved, and who can blame them?” said Chonko at Siglent. “Electromagnetics is not trivial, and designs are becoming increasingly complex. Most EMC-targeted instrumentation is also expensive. Since many companies are trying to achieve compliance certification without breaking the bank, Siglent’s goal is to provide tools that get the job done with minimal cost. Quasi-peak detector capability, multitrace viewing, spectrum/waterfall charting, on-screen limit lines, and real-time spectrum acquisition are all features that help lower EMC test time, and Siglent delivers them at affordable prices.”

Gross at Rohde & Schwarz said customers look for easy-to-handle test software for pre-compliance tests during the product development, as well as for automated compliance tests. “To meet these needs, Rohde & Schwarz will successively replace its well-known R&S EMC32 automation software,” he said. “The new R&S ELEKTRA EMC test suite facilitates interactive and/or fully automated measurements for pre-compliance and certification tests for both electromagnetic interference (EMI) and electromagnetic susceptibility (EMS) for all relevant standards.”

Gross also noted that engineers are starting their EMC investigations earlier in the development process, adding that Rohde & Schwarz helps with spectrum analyzers suitable for these tasks. “In combination with the new R&S FPL1-K54 EMI measurement option, the R&S FPL1000 all-round spectrum analyzer measures emissions in line with CISPR and MIL standards and makes fast pass/fail decisions,” he said.

“The spectrum analyzer remotely controls LISNs, and has the corresponding correction factors built-in. For pure debugging tasks, the R&S FPC1000 spectrum analyzer together with the high-quality R&S HZ-17 near-field probe set and the R&S HM6050-2 LISN is a good choice. This combination allows developers to detect both radiated and conducted interference.” The R&S ELEKTRA EMC test software supports analyzers as well as other instruments and accessories, he added.

Mologni at Ansys commented that the company’s simulation tools are used in the early stages of a development cycle. The tools, “…empower engineers to tackle different problems such as signal integrity, power integrity, EMI, and radio-frequency interference (RFI).”

He added that many electrical and thermal issues that affect PCBs—EMI, crosstalk, power integrity, overheating, etc.—adversely impact the overall signal integrity of electronic devices. Automated techniques combine the best attributes of two solvers—in this case, the accuracy of HFSS and the speed and capacity of SIwave—to mitigate SI problems of high-speed data channels in complex and dense printed circuit boards.

“Automatic adaptive mesh refinement techniques in Ansys EM tools accurately model complex PCB, IC, and package designs for DCIR analysis to predict the power integrity of these designs,” Mologni said. “Design-rule checkers in Ansys tools identify potential problems in high-speed electronic systems prior to running simulations, saving time and effort which may otherwise be spent in making costly design changes late in the development cycle. These simulations eliminate errors and reduce PCB re-spins.”

vanEijkelenburg at Pacific Power commented that for final test, full compliance to the applicable standard is of paramount importance. “This also implies that measurements must be both repeatable and reproducible,” he said, adding that other important issues are the ability to test a wide range of products in terms of power level and phase modes with as much sharing of test hardware resources as possible to manage test system cost. “Finally, report generation that documents compliance of the product is important for audit and verification purposes,” he added.

vanEijkelenburg also commented on a growing trend toward the need for ever higher power levels, driven by larger solar installation and thus larger PV inverter sizes. This is coupled with EV charging infrastructure demands for faster charging, and thus higher voltage and power needs. “To meet these growing power needs, our ECTS2 EMC test systems are available up to 90 kVA with higher configurations available as needed,” he said.

Yasami at Anritsu said Test instruments must provide engineers with an overall simple and efficient test process—including ease of use, automation of test cases, and uncomplicated control of the device under test (DUT) without the need to manually configure the DUT or incorporate specific test modes. “5G NR devices and User Equipment (UE) utilize Frequency Range 1 (FR1) and Frequency Range 2 (FR2) frequencies, which include sub-6-GHz and mmWave spectrums, respectively,” he added. “5G NR equipment requires more complex test setup and execution. Engineers must rely on industry-leading technology, such as that incorporated in the MT8000A and MT8821C, to accurately test devices and UE so they can be certified in a timely manner.”

REFERENCES

1. EMC Precompliance Testing: Near Field Probing, Application Note, Saelig Co. Inc.

2. Immunity testing example using Tekbox TEM Cells, Application Note, Saelig Co. Inc.

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.