Rugged Absolute Digital-Output Barometer Includes Charge-Sensing Channel

Check out our Sensors Converge 2023 coverage.

Along with temperature, pressure is one of the most widely measured physical variables. And like temperature, it has several regions: low pressure for biological phenomena (~2 psi/150 hPa/150 millibar); mid-range consumer, scientific, and commercial (tens to hundreds of psi); and high-pressure advanced applications (thousands of psi).

Addressing that low-to-mid range is STMicroelectronics’ ILPS28QSW piezoresistive barometric-pressure sensor in a sealed, cylindrical, seven-contact ceramic surface-mountable package (designated CCLGA-7L, just 2.8 × 2.8 × 1.95 mm) (Fig. 1).

It provides absolute pressure readings accurate to within 0.5 hPa with selectable full-scale ranges of 260 to 1,260 hPa and 260 to 4,060 hPa, and wide operating-temperature range of −40 to 105°C. Its high-accuracy and precision 24-bit readings, along with superior environmental robustness, make it a good fit for applications such as gas- and water-metering equipment, weather monitors, smart filters, HVACR (heating, air conditioning, ventilation, and refrigeration) systems, and home appliances.

What’s an hPa? A hectopascal equals 100 pascals—the SI unit for pressure. It also equals 1 millibar. The hectopascal is the SI unit for measuring atmospheric or barometric pressure (nominal atmospheric pressure at sea level is about 1,000 millibars). Due to its low value, the hectopascal is well suited for assessing gas pressures, such as air flow differentials in air-conditioning systems or wind tunnels, too. Note that 1 hPa is equal to ~0.0145 pounds/square inch (psi).

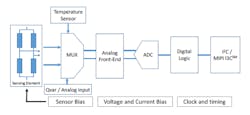

Within the sensor is a significant amount of electronics (Fig. 2). It operates form a 1.7- to 3.6-V supply with operating current as low as 1.7 µA. The ILPS28QSW integrates digital features that simplify system design and management, including temperature compensation, FIFO memory, and an I2C/MIPI-I3C digital communication interface, with an output data rate that’s selectable from 1 to 200 Hz (Fig. 3).

In addition, an embedded “Qvar” (electric charge variation detection) channel can be enabled for sensing in applications such as water-leak detection, tap, double tap, long press, and L/R - R/L swipe.

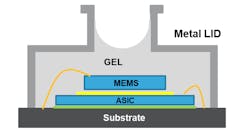

With many pressure sensors, the story is as much about the package as the sensor element itself (Fig. 4). This unit features a ceramic substrate that provides high resistance to liquid permeability and a robust potting gel, proven in automotive applications, to protect the internal circuitry. The package is “holed” to allow external pressure to reach the sensing element.

The electrically floating lid is made from high-grade surgical steel sealed with an O-ring and secured with epoxy adhesive. It can be connected to ground or left unconnected. This unique package ensures an ingress-protection rating of IP58 to withstand immersion in over one meter of water, certified according to IEC 60529 and ISO 20653. In addition, the sensor can sustain up to 10-bar over-pressure.

Support for the sensor comes from two sources: a comprehensive 52-page datasheet and the STEVAL-MKI223V1K demonstration board (Fig. 5). The latter is a kit made up of an ILPS28QSW pressure sensor mounted on an “ad hoc” PCB, with a Qvar electrostatic sensor and a swipe electrode to make it compatible with the STEVAL-MKI109V3. The kit provides the complete ILPS28QSW pinout for a standard dual inline (DIL) 24-pin socket and comes ready-to-use with the required decoupling capacitors on the VDD power-supply line.

The ILPS28QSW is in production now, priced from $3.00 for orders of 1,000 pieces.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.