Download this article in PDF format.

It’s been obvious for decades that the microelectromechanical systems (MEMS) switch could potentially replace PIN diode, mechanical, FET, and other types of switches in a broad swath of RF and microwave applications. A MEMS switch has almost everything an engineer could ask for: It’s smaller and lighter than any other switch technology; has very little insertion loss; provides very high isolation; can operate well into the millimeter-wave region; has exceptionally low intermodulation distortion; and can handle reasonable amounts of RF power.

So why didn’t RF MEMS switches take the world by storm years ago? The answer lies in the obstacles that have defied developers’ efforts to tame them, primarily suitability for low-cost mass production and demonstrated reliability over billions of switching cycles.

However, it now appears that 35 years after IBM described the first “microelectromechanical” switch, and more than a quarter-century after Analog Devices introduced the world’s first commercial MEMS product (an accelerometer), the technology has finally overcome these hurdles. To understand why it took so long to get here, it’s important to understand the topsy-turvy development of the MEMS switch.

Sponsored Resources:

- Advances in semiconductor technology reduces the need to use large conventional relays in RF switching

- Fundamentals of Analog Devices' Revolutionary MEMS Switch Technology

- Making MEMS switch technology a commercial reality

MEMS Memory Lane

IBM’s development marked the first time that semiconductor fabrication techniques were used to make tiny mechanical structures in silicon that were moved electrically. It showed that such a device could combine the benefits of semiconductor manufacturing processes with the inherent characteristics of electromechanical relays. The rewards were potentially so enormous, especially for defense systems, that Hughes Research Labs, Raytheon, Rockwell, and others devoted large sums of money and time to bring RF MEMS switches to fruition.

Their work solidified their belief that not only could these devices be smaller than even the smallest PIN diode, FET, or other solid-state switch, they could be orders of magnitude smaller than electromechanical types that, although invented before the Civil War, resigned supreme (and are still in use today). The next step seemed obvious: Refine the manufacturing process and solve reliability issues, and a few other less-thorny problems. After masses of journal papers were written, patents applied for, and other efforts by dozens of organizations throughout the world, commercial devices remained as far away as ever.

By this time, in the early 2000s, MEMS marketing had reached a fever pitch, promising that the remaining problems associated with MEMS switches would be soon swept away. Startups were formed to fabricate and develop commercial products, and defense and commercial customers awaited the outcome. What they got instead were sampled devices that delivered neither the required reliability or wafer-to-wafer consistency that had been promised.

As Will Rogers famously said, “you never get a second chance to make a first impression,” and that appeared to be the fate of the MEMS switch. The unfulfilled promises made designers wary of using MEMS switches and sometimes MEMS technology in general. MEMS developers folded or were absorbed by larger companies, and the technology’s remaining champions doubled down to make sure that the next chance, if it came, would convince the skeptics.

Analog Devices was the first to stand and deliver. Other device prototypes were demonstrated by Radant MEMS (later absorbed by CPI) and TeraVicta Technologies (now defunct), which has left Analog Devices is one of the few remaining manufacturers of commercially available packaged MEMS switches, which is still the case today.

Surviving and Thriving with MEMS

It’s an enviable position for the company, as the wireless industry is faced with the need to switch more frequency bands within the confines of a smartphone. For instance, the defense industry has wholly adopted the active electronically steered array (AESA) radar architecture, in which a switch is required at each of its hundreds or thousands of elements.

Among the host of other applications that could benefit is filter-bank switching in measurement systems, which needs streamlining. That includes the possibilities presented by IoT applications in which small size, high performance, and (ultimately) very low cost are key drivers.

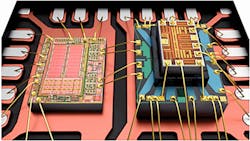

1. The ADGM1004 SP4T MEMS switch sits on top of a “classic” DPDT electromechanical relay.

Having been involved with MEMS development for three decades, Analog Devices made sure that when it introduced its latest MEMS SP4T switches (Fig. 1), the ADGM1004 and ADSM1304, that operate from dc to 13 and 14 GHz, respectively, all likely questions would be answered.

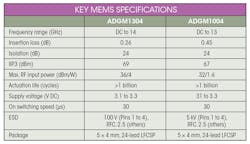

For example, both devices are about 95% smaller, 10X more reliable, 30X faster, and consume 10X less power than a typical RF switch. They’re available in quantity, have demonstrated reliability over more than 1 billion switching cycles, and use advanced packaging techniques to ensure high resistance to electrostatic discharge, the latter being one of the major challenges over the years.

The switches are also characterized for hot-switching, an undesirable condition in which RF power is passed through the switch before it’s closed, typically reducing operating life by a factor of up to 10. In contrast, the ADGM1004 and AGSM1304 have been demonstrated to have an MTBF of at least 3.4 billion cycles at an operating frequency of 2 GHz with a 10-dBm RF signal.

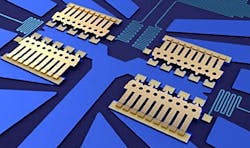

2. Shown is the MEMS die and driver IC in the SMD QFN package.

The switches contain two die, the switch and the low-voltage, low-current supply IC, to drive it (Fig. 2). The driver IC is compatible with CMOS logic drive voltages, and the pair are housed in a 5- × 4-mm, lead-frame chip-scale package.

The switching mechanism is an electrostatically actuated, gold, cantilever-beam that resembles a tiny relay with metal-to-metal contacts that are actuated by relatively high dc voltage. Four of the cantilever switch beams (for a SP4T configuration) are shown in Fig. 3.

3. Four MEMS cantilever switch beams are used in the SP4T switches.

The ADGM1004 is designed to deliver extremely high ESD resistance using a dedicated circuit to produce a human-body-model (HBM) rating of 5 kW at the RF1 through RF4 pins, and RFC pins and 2.5 kW for all others—claimed to be the highest of any MEMS switch in the industry. The circuit has little or no effect on RF switching performance. Key specifications are shown in the table.

Unlike the many other functions for which MEMS devices have been commercialized for many years, RF switches present unique challenges. Achieving wide bandwidths, high reliability, and commercial producibility in a tiny RF MEMS switch has been an elusive goal since the technology was first realized. However, after countless efforts by organizations ranging from DARPA to defense contractors, academia, private research organizations, and other entities, the path is now open for MEMS to deliver performance unachievable by any other technology.

Sponsored Resources:

- Advances in semiconductor technology reduces the need to use large conventional relays in RF switching

- Fundamentals of Analog Devices' Revolutionary MEMS Switch Technology

- Making MEMS switch technology a commercial reality

Related Reference:

• Video: Fundamentals of Analog Devices’ RF MEMS Switch Technology