Enhance Hearing-Aid Performance with Optical Proximity Sensing

What you’ll learn:

- Understanding acoustic feedback in hearing aids.

- Power consumption challenges in hearing aids.

- Functionality integration and its impact on energy consumption.

- The benefits of using photoreflectors for proximity detection.

Hearing aids considerably improve the quality of life for individuals with mild to profound hearing loss by enhancing their ability to communicate and interact with others, and by enabling them to hear sounds they might otherwise miss. Hearing aids come in different flavors, including those that fit behind the ear, inside the outer ear, or within the ear canal. The latest devices are sophisticated, offering advanced features like wireless connectivity, noise reduction, the ability to be controlled with a smartphone, and much more.

This article will explore the benefits of incorporating optical proximity sensors, or photoreflectors, into hearing aids. It will outline operating principles and functionality of photoreflectors, discuss the problems posed by acoustic feedback in hearing aids, and explore how ROHM’s ultra-compact optical proximity sensors can help mitigate these issues.

Understanding Acoustic Feedback in Hearing Aids

Acoustic feedback in hearing aids occurs when the sound amplified by the receiver (or speaker) is inadvertently picked up by the device's microphone and subsequently re-amplified, creating a feedback loop. Feedback results in a high-pitched “whistling” sound that can be uncomfortable or even embarrassing for users. It also degrades the sound quality, making it difficult for users to understand speech and other sounds.

Several factors can contribute to acoustic feedback in hearing aids, including:

- Earmold leakage: One of the primary contributors to acoustic feedback is the leakage of sound from the earmold. Earmolds are custom-fitted to the user's ear canal, but over time, changes in the ear canal shape due to aging, weight loss, or weight gain can create small gaps. These gaps permit amplified sound from the hearing-aid speaker to leak and re-enter the microphone, creating a feedback loop.

- Device orientation: The relative position of a hearing-aid microphone and speaker can determine feedback. Movements like tilting the head, chewing, or even facial expressions can alter the orientation, creating a pathway for sound to travel from the speaker back to the microphone.

- Venting: Vents in hearing aids are designed to reduce the “occlusion effect,” a condition where a user's voice sounds overly loud and distorted inside their head. However, vents can also serve as channels for external sound to enter or exit, contributing to feedback.

- High-gain settings: Hearing aids are designed to operate at high amplification levels, particularly for users with severe hearing loss. However, the higher the gain, the likelier it is for sound to escape the earmold and be picked up again by the microphone, creating feedback, e.g., in crowded rooms or windy outdoor settings.

Common methods for reducing the acoustic feedback in hearing aids include tighter earmolds, feedback cancellation algorithms, and limiting the overall gain or volume of the device. These methods, while effective to an extent, can come with tradeoffs such as discomfort to users or reduced sound quality.

Battery Consumption Challenges in Hearing Aids

Battery consumption presents a significant challenge in hearing aids given the small footprints of these devices and the need for continuous operation. The main issue is achieving a balance between power consumption and functionality of the device, as hearing aids require power for various functions like signal processing, amplification, noise reduction, and wireless connectivity.

As hearing aids become smaller and more discreet, the space to integrate batteries is shrinking, and miniaturization poses a challenge to maintaining long battery life without compromising size and user comfort. The result is increased demand for batteries that are not only small in size, but more efficient and longer lasting.

Rechargeable batteries, for instance, achieve longer life spans and are more eco-friendly than disposable types. Li-ion batteries commonly utilized in consumer electronics are now being adapted for hearing aids, offering higher energy densities and durable operation compared to traditional zinc-air batteries.

GPS Integration and Its Impact on Energy Consumption

GPS technology in hearing aids enables device tracking, which can help locate lost or misplaced devices. This feature is invaluable, given the small size and high costs of hearing aids. However, GPS considerably impacts energy consumption, as GPS modules consume substantial power to establish and maintain connectivity with satellites and provide location information.

To mitigate the impact on battery life, several design considerations must be taken into account:

- Power-efficient GPS modules: Utilizing GPS modules that are specifically designed for low power consumption is crucial for extending battery life. Power-efficient modules may employ strategies like duty cycling, where GPS is activated at predetermined intervals.

- Smart power management: Incorporating intelligent power-management systems that activate GPS functionality only when necessary (for example, when the hearing aid isn’t in its storage case) can reduce power drain.

- Hybrid location technology: Combining GPS with lower-power location technologies, such as Bluetooth Low Energy (BLE), provides a balance between location accuracy and power consumption.

Benefits of Incorporating Photoreflectors in Hearing-Aid Devices

Photoreflectors, also known as optical proximity sensors, detect light and reflectivity changes in the environment. These devices consist of a light source (typically an LED) and a photodetector, such as a photodiode, placed side by side. The LED emits a beam of light that, upon hitting a surface, has a portion reflected and captured by the photodiode. The intensity of this reflected light varies depending on the proximity and reflectivity of the surface in front of the sensor.

In hearing aids, the primary function of a photoreflector is to detect the presence and distance of external objects, particularly those close to the ear. This capability is important for two reasons: minimizing acoustic feedback and conserving battery power.

Photoreflectors offer several advantages in hearing-aid applications. First, their small size and low power consumption eases integration into compact and energy-efficient designs. Moreover, they provide a non-invasive medium for proximity detection, which enhances user comfort while maintaining functionality.

Unlike mechanical switches or buttons, photoreflectors function without physical contact, ensuring the hearing aid's integrity and durability. By integrating photoreflectors into hearing aids, designers and engineers can also enhance user experience by enabling smart features—for example, they can turn the device on/off when placed in or removed from the ear.

Acting as proximity sensors, photoreflectors can attenuate acoustic feedback in hearing aids by detecting the proximity of objects, such as fingers or clothing near the device, and prompting the device to adjust its settings dynamically.

For example, when an object is detected close to the hearing aid, the device can reduce the amplification level or alter sound-processing algorithms to minimize the risk of feedback. This adaptation enhances the user experience by providing more reliable sound quality, especially in situations where the user is adjusting the device or when the hearing aid is exposed to environmental conditions.

Photoreflectors can also contribute to energy conservation in hearing aids by detecting whether the hearing aid is in use (e.g., when the device is in the ear) or not being used (e.g., when removed and/or placed on a surface). The sensors then automatically switch between active and standby modes. In the latter, the device conserves power by idling energy-intensive components, such as the amplifier and digital signal processor.

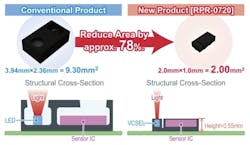

For instance, ROHM’s RPR-0720 is an optical sensor module that incorporates a vertical-cavity surface-emitting laser (VCSEL) as the light emitter (offering superior directivity compared to conventional LEDs), complemented by a sensor IC for reception. The device has a 2.0- × 1.0- × 0.55-mm footprint, achieved by optimizing the module structure using proprietary technology.

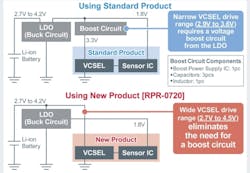

This design drastically decreases the sensor area (~78% smaller compared to competitor solutions), making it suitable for smaller hearing aid designs (Fig. 1). The RPR-0720 operates within an input voltage range from 2.7 to 4.5 V, facilitated by the VCSEL, which allows for the module to function without a peripheral booster circuit when using a lithium-ion battery.

Hearing-Aid Applications

ROHM’s RPR-0720 optical sensor module improves user interaction through its attachment and detachment detection capabilities. When the sensor detects that the hearing aid is close to the ear, it automatically activates the device. Once the hearing aid is removed, the sensor switches it back to standby mode. Such responsiveness mitigates the risk of the device being accidentally left on, which can drain the battery, and minimizes exposure to environmental elements that may impact the hearing aid’s durability.

The RPR-0720 can also dynamically adjust device settings in response to its proximity to objects like clothing or the hands to prevent feedback or discomfort, ensuring a more comfortable experience. For instance, it’s able to automatically lower volume levels or adjust sound processing when an object is detected close to the hearing aid. Combined with GPS technology, the RPR-0720 sensor can also assist in locating misplaced devices.

Conventional sensors in hearing aids typically require a voltage booster circuit (usually a power-supply IC, three capacitors, and one inductor) to match the voltage requirements of the sensor (2.9 to 3.6 V is required to enable the VCSEL driver). This adds complexity and occupies valuable space within the device.

The RPR-0720 optical sensor module provides a direct connection to lithium-ion batteries, avoiding the need for a booster circuit to save cost, simplifying the overall design (Fig. 2). A direct connection also ensures that more of the battery's power is used for the primary functions of the device, thus extending battery life.

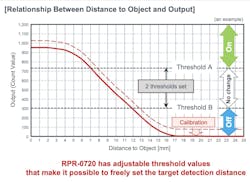

The sensor module offers an adjustable detection range of 1 to 15 mm. This adjustability, managed via the I2C interface, allows designers to fine-tune the sensor's proximity detection. In practical terms, this means that the RPR-0720 can be calibrated to accurately detect the specific distances relevant to a user's interactions with their hearing aid—for instance, the proximity of the hand when adjusting or taking off the device (Fig. 3).

Via an I2C interface, the device enables communication at speeds of up to 400 kHz in fast mode, suitable for rapid data transfer. I2C compatibility also reduces pin count and simplifies scaling, enabling easy integration into hearing aids.

There’s also a constant-current configurable driver for the VCSEL that helps deliver stable sensor operation and stabilize the light output. Furthermore, the driver’s configurability means that current can be adjusted to suit varying operational requirements, offering flexibility in application design.

In addition, the RPR-0720 has an ambient-light-canceling function, enabling the sensor to distinguish between light emitted by the VCSEL and light from the environment to maintain a high degree of accuracy and reliability in a wide range of environmental conditions.

To address light leakage, micro slits in the package design effectively contain the light emitted by the VCSEL within a defined path, preventing it from dispersing into other areas of the sensor. In hearing aids, this means more reliable and responsive control over features like automatic feedback reduction and power management based on the user's actions.

Benefits of Optical Proximity Sensors

Incorporating optical proximity sensors into hearing aids can improve the functionality and user experience, reducing acoustic feedback by dynamically adjusting the device settings based on the proximity of objects. These sensors also conserve energy by enabling the device to automatically switch between active and standby modes based on usage, which is invaluable, due to their continuous operation.

Solutions like ROHM’s RPR-0720 optical sensor module can offer a number of benefits for hearing aids in terms of energy efficiency and enhanced user experience. Its small size and efficient operation, due to the use of VCSEL technology and a specialized sensor IC, makes the sensor highly accurate and adaptable to various environments and user interactions.

About the Author

Aki Hashimura

Technical Product Manager/Application Engineering. ROHM Semiconductor

Aki Hashimura is Technical Product Manager for Application Engineering at ROHM Semiconductor.