Because the handheld DMM market is segmented by application, the instruments vary greatly in performance, accuracy, and price. There is an amount of overlap, but as André Rebelo of Extech Instruments commented, “Different users have different needs, and we’ve tried to offer options for every application and every budget. Benchtop testing of sensitive electronic components may demand high accuracy or extra digits of resolution…. Electrical workers testing line voltage often can identify problems within a wider window of variances and may not need 0.06% accuracy or 500,000-count display.”

AEMC Instrument’s John Olobri, director of sales and marketing, agreed. “Field work generally does not require higher accuracy. Most 4,000- to 10,000-count meters will provide enough accuracy and resolution. Lab work and product design verification require higher 40,000- to 100,000-count meters with higher accuracies,” he said.

Greg Von Rehder, product marketing director at B&K Precision, provided a contrasting view. He said, “Today, many of our customers already expect handheld DMMs to have the same kinds of measurement capabilities found in our benchtop DMMs… and understand accuracy is the main differentiator. Typical applications for high-accuracy requirements include electricians working in commercial buildings or field service technicians who need not just portability and safety, but also the confidence that the measurements they make in the field are accurate and reliable enough to keep their systems running.”

To help users select the most suitable products, we asked manufacturers to discuss some of the more popular features beyond the usual voltage and current measurements. Certainly, there are many unique functions that could be the answer to specific application requirements. On the other hand, the replies we received suggested that it’s wrong to quickly skip over the voltage and current capabilities, assuming they are the same as they’ve always been.

Voltage

It’s obvious that a 3½-digit meter doesn’t address the same applications as a 6½-digit one. However, resolution does not determine where the measurement ranges have been positioned or the number of ranges. The lowest range on Agilent Technologies’ 6,000-count Model U1233A is 600 mV and the highest 600 V. In contrast, AEMC’s 6,000-count Model 5233 begins with 60-mV and has ranges up to 1,000 V.

Courtesy of AEMC Instruments

What you tend to get in a higher resolution, more expensive meter is greater accuracy on the DC ranges—0.03% + 5 counts for voltage measurements in Agilent’s 50,000-count U1253B. Autoranging also should be included although it’s not limited to high-end models. However, a meter’s AC performance seldom matches the DC numbers. In addition to variations in full-scale values, AC voltage and current specifications require careful reading because several factors are involved. The first consideration regards the type of signal you need to measure: AC, or a mixed AC+DC. Some models don’t support AC+DC measurements.

Is the signal sinusoidal? Early models of true-rms AC meters thermally measured the power in a waveform and displayed the result as rms volts. Analog ICs that compute rms have displaced thermal techniques, and if a meter’s sampling circuitry is sufficiently fast and accurate, the signal’s rms value can be calculated. Almost all relatively expensive professional-grade DMMs support true-rms AC measurements. This is not necessarily the case for very inexpensive meters.

The AC ranges on a DMM without a proper true-rms function are average reading and scaled to be correct for a sinewave. If you try to measure any other waveform, the answer will be in error. Nevertheless, even when a DMM has a true-rms feature, users must be wary.

Agilent’s U1230 Series of 6,000-count DMMs specifies 1.0% + 3 counts AC voltage accuracy from 45 Hz to 500 Hz. However, at the very end of the general specifications, assumptions are listed. Among these is the note, “For nonsinusoidal waveforms, add (2% reading + 2% full scale) typical.” Even though these meters feature true-rms measurements, the results are much more accurate for sine waves than for other wave shapes.

Yet another factor enters the discussion at this point. The U1230 Series Meters are low cost, the U1233A listing for $168 as shown in the large comparison chart accompanying this article. Competing meters may have exactly the same sensitivity to nonsinusoidal waveforms, but it isn’t specified.

To see the comparison chart, click here.

What is and is not included on a datasheet depends on the DMM’s lineage as well as the size of the datasheet itself. It’s always good practice to make sure that all the specs relevant to your application are listed. If they are not, the manufacturer may be willing to provide the missing ones in writing, or you might do well to select a different, probably higher price meter that does guarantee those parameters.

AC measurement accuracy also varies with frequency and range. As an example, Agilent’s U1253B specifies 0.4% + 25 count accuracy for 45 Hz to 1,000 Hz and for ranges from 500 mV to 500 V. In this frequency band, the error increases to 0.4% + 40 counts for both the 50-mV and 1,000-V ranges. However, it also increases at lower and higher frequencies, reaching 3.5% + 120 counts for most voltage ranges and frequencies from 15 kHz to 100 kHz. The comparison chart lists the frequency band that corresponds to a DMM’s stated accuracy and does not imply that the AC measurements are limited to this band.

Although the 50,000-count U1253B has an overall 4½-digit rating, 40 counts of uncertainty are equivalent to four counts in a 3½-digit DMM. So, this is yet another area in which comparing specifications can be both confusing and rewarding. Additional resolution usually costs more, but if the measurement uncertainty also has increased, you may not be gaining a lot.

Fluke has expanded the remote measurement capabilities introduced in the Model 233. The new CNX 3000 Series Test Tools support simultaneous wireless readings from up to three remote modules as well as the DMM itself. For applications requiring more measurements, up to 10 modules can be logged simultaneously to a PC.

A typical benefit of the remote module system is removal of the end user from the arc flash zone in high-power electrical tests. In addition to the basic DMM, separate modules address AC voltage, clamp-style true-rms current, Rogowski-style true-rms current, and K-type temperature.

Popular Functions

Temperature, Continuity

Agilent’s Ban-Kwan Wong, handheld product planner, said that many customers frequently used temperature and continuity measurements. Most handheld DMMs buzz to indicate continuity. In addition, Wong explained, the backlight on several Agilent DMMs flashes as a visual indication of continuity. He said that temperature monitoring or profiling was especially important when the quality of the end product was related to temperature.

Courtesy of Extech Instruments

Many DMMs measure temperature by scaling the Seebeck effect voltage generated by a Type K thermocouple. The meter circuitry includes cold-junction compensation that generates an offset voltage corresponding to the meter’s temperature. Several notes in the temperature section of Agilent’s U1230 specification discuss various errors that can occur because of differences in ambient temperature. For example, these meters have a null capability that reduces the test lead’s thermal effect. For the most accurate results, the thermocouple probe and meter should be placed close to each other so they both see the same ambient.

An infrared thermometer function is available in a few DMMs. Extech’s Rebelo commented, “In industrial and electrical applications, being able to measure temperature at a distance from dangerous or hard-to-reach components can be an essential measure of safety. More generally, infrared offers laser-targeted, point-and-shoot measurement convenience that makes multiple sequential measurements quicker and easier [than using a temperature probe.]”

Resistance

An accurate resistance reading usually can be made by measuring the voltage that results from passing a constant current through the DUT. Of course, there is the small resistance of the test leads to consider, and some meters have a null capability that can subtract that amount from the total. Handheld DMMs don’t support Kelvin 4-wire measurements.

However, in some applications, the size of the test current can make a big difference. Especially for lower Ohms ranges, a relatively large test current can cause DUT self-heating, leading to resistance changes and measurement errors. Model TY720 from Yokogawa Corp. of America includes a LowPower-Ω mode that reduces test current by a factor of 25: on the 5-kΩ scale, a 10-μA test current is used rather than the standard 250 μA. Self-heating is greatly reduced but accuracy suffers. For this range on this meter, accuracy reduces to 0.2% + 3 counts from the initial 0.05% + 2 counts at the higher test current.

Resistance measurements made on high value ranges are susceptible to errors caused by unintentional shunt paths. This effect could be caused by something as simple as a dirty circuit board. A clue to the level of sensitivity involved is given by a reduction to 60% for the relative humidity limit associated with Agilent’s U1253B’s 50-MΩ and 500-MΩ ranges. Obviously, this type of consideration also must accompany Extech’s MG300 Insulation Tester with a maximum 4,000-MΩ range, but no humidity level is specified.

Offset voltage also can be problematic when measuring resistance. Because resistance is calculated from the voltage drop measured across the DUT, any additional voltage not caused by the test current results in measurement error. Benchtop DMMs have provided various schemes to overcome this problem for several years, but only a few handheld DMMs can eliminate residual voltage errors. Agilent’s Model U1272A DMM features the Smart Ohm Mode that measures the DUT voltage with the test current turned off, then measures the DUT voltage with the test current turned on and uses the corrected DUT voltage to calculate resistance.

Frequency

Although DMMs measure frequency, the input conditions vary with rate. For example, B&K Precision’s Model 2712 specifies 1-V rms from 5 Hz to 100 kHz but 2 V rms for 100 kHz to 500 kHz. In addition, pulses must be at least 2-μs wide and the duty cycle between 30% and 70%. Agilent’s U1253B breaks down sensitivity vs. frequency range into four bands, sensitivity varying from 0.1 V rms from 0.5 Hz to 100 kHz to 0.6 V rms on the 100-MHz range.

Yokogawa specifies the TY720 slightly differently although the end result is similar. Rather than state a minimum voltage level up to 10 kHz, the frequency measurement specification requires a signal between 10% and 100% of the input voltage or current range. For the 100-kHz range, the limits change to between 40% and 100%.

Special Functions

Terminal Shutters

Yokogawa’s Greg Hendry, product manager, said, “One unique feature of our TY500 and TY700 Series DMMs is the terminal shutters that open and close per the function switch position. This is a safety feature that reduces the likelihood of a customer connecting the test leads incorrectly during operation, which, in turn, better protects the DMM from damage and the operator from harm.”

Noncontact Voltage Sense

AEMC, Extech, and Agilent offer DMMs with a noncontact voltage sensing capability. AEMC’s Olobri explained, “[With noncontact voltage detection,] the user can determine if a cable or outlet is live by placing the meter near it. The display will light up red in the presence of voltage.”

Extech’s Rebelo added, “While this feature does not offer metric information per se, the value of this auxiliary feature is indispensable. [It enables] a user to simply push a button and hold the tester near wiring, fixtures, or outlets to ensure equipment has been properly de-energized for safe repairs.”

Low-Impedance Input

Noncontact voltage detection depends on a high input impedance, but this can lead to confusing readings under some circumstances. For example, probing a totally disconnected high-impedance point physically close to an energized circuit could lead the DMM operator to conclude that the disconnected point actually was connected. Agilent’s U1230 Meters have a low input impedance mode that sets the meter to the 600-V range and reduces the input impedance from 10 MΩ to 3 kΩ, eliminating what the company terms “ghost voltage measurement.”

Wireless Connection

Agilent’s Wong described the wireless remote connectivity capability provided by the combination of the U1177A Bluetooth Adaptor used with the Android Mobile Meter app or the GUI Datalogging software used with a PC. These solutions allow you to remotely and simultaneously read the responses of up to three DMMs.

Courtesy of Yokogawa Corporation of America

Environmental Extremes

Several Agilent DMMs use organic LED (OLED) display technology, which, according to the company, is easier to read even in dark, off-angle situations. Wong added, “The newest U1273AX OLED DMM pushes the envelope further by enabling our customers to take measurements even at -40°C without the need to warm up the DMM. This is particularly important for oil and gas facilities, telecommunications base stations, wind farms, and automotive testing during winter or in an environmental chamber.”

Insulation Testing

Extech’s MG300 DMM provides a 1-kΩ to 4,000-MΩ insulation resistance testing capability driven by internally generated 125-, 250-, 500-, or 1,000-V test voltages. The meter includes a full complement of the usual DMM voltage, current, and resistance ranges as well as frequency, capacitance, and temperature measurement capabilities. In addition, the built-in 915-MHz or 433-MHz wireless interface supports continuous data streaming to your PC.

Delta T

Some meters can automatically measure the difference between two temperature readings. The readings can be made simultaneously using two sensors or sequentially using the same sensor twice. According to Extech’s Rebelo, this feature ensures more accurate readings than result from manually calculating the difference.

4- to 20-mA Loop Simulation

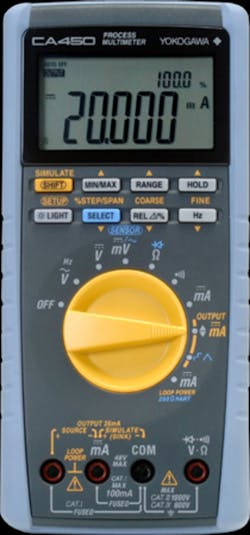

Industrial control systems traditionally work with current values between 4 and 20 mA. Fluke’s Model 789 ProcessMeter and Yokogawa’s Model CA450 Process Multimeter provide the usual DMM functions but also can power a loop from a 24-V source. In addition, a switchable 250-Ω resistance supports use of the meter as a second master in HART-enabled systems. A built-in span/step/sweep generator switches between a 4-mA or 20-mA output, steps between those limits in 4-mA increments, or sweeps between the limits over a 15-s or 40-s period.

Conclusion

Aside from the case color, most DMMs have about the same overall appearance, which can be deceiving. Literally hundreds of different models are available, accuracy and resolution being the two largest factors distinguishing one meter from another, but certainly not the only ones.

After determining that a meter satisfies your basic measurement requirements, selecting one with extra features that you actually will use can make the purchase very economical. Special measurement capabilities, convenience features, or additional safety aspects easily pay for themselves in the time they save and the greater confidence they give.