All-digital phase-locked loop offers sub-mW power consumption

The Intuitive Internet of Things, or I2oT, is a concept imec has been working to bring to fruition. Speaking at the imec Technical forum held in conjunction with SEMICON West 2015, Luc Van den hove, imec’s president and CEO, described the concept, choosing wearable technology as an example. To be successful, he said, wearables will have to fade into the background of your life and employ smart, personalized algorithms that take into account context, intention, and emotional state—hence the term “intuitive.”

The 2017 International Solid-State Circuits Conference, held in February in San Francisco, offered imec the opportunity to further elaborate on the I2oT, which relies on tiny sensor nodes invisibly embedded in the environment and wirelessly connected to the Internet. A bulky battery would prevent such a node from fading invisibly into the background. Further, as billions of IoT devices are deployed, battery replacement could become impossible. Therefore, imec has been working to cut power consumption, especially as related to wireless connectivity.

In the latest power-reduction effort described at ISSCC, imec, Holst Centre, and ROHM teamed up to present an all-digital phase-locked loop (ADPLL) for IoT radio transceivers (Figure 1).

Courtesy of imec

The PLL traditionally has been an analog component—a major power consumer that can take up 30% of a radio area. Consequently, the research community has been working on digital alternatives. All-digital PLLs enable a smaller footprint, better control and testability, and improved scaling to advanced CMOS nodes. However, to date, they have lagged behind in terms of performance compared to analog solutions.

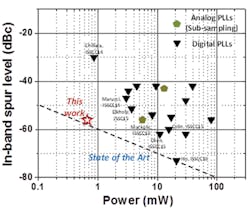

That’s the problem imec, Holst Centre, and ROHM teamed up to solve. Their new ADPLL features a small area (0.18 mm² in 40-nm CMOS) and low power consumption (0.67 mW) while limiting all spurs lower than -56 dBc and keeping jitter below 2 ps (Figure 2).

Courtesy of imec

The new all-digital PLL supports all specifications of Bluetooth low energy radios while reducing cost and power consumption below any of today’s solutions. To achieve its level of performance, the dividerless fractional-N digital PLL features a power-efficient spur-mitigation technique and a digital phase unwrap technique.

“We are pleased with our collaboration with ROHM to solve yet another challenge and deliver an ADPLL that adds to imec’s record low-power-radio design portfolio,” said Kathleen Philips, program director at imec/Holst Centre for Perceptive Systems for an intuitive IoT. “With this performance, this all-digital PLL has become a mature and superior alternative to the widespread analog PLLs. The ADPLL is ready for industrial mass production and currently is being transferred to our industrial partners for product integration.”

When asked about prospects for scaling, she said, “The roadmap toward 22 nm is very promising: The relative benefits of the ADPLL become more and more significant as you go down in technology node.” At 22 nm, she said, “Power-consumption and silicon-area benefits, as compared with analog PLLs, become even more pronounced than the improvements that we have already realized in 40 nm.”

She continued, “Maybe even more important, porting to small nodes and other fabs will be faster as compared to the redesign needed for a classical analog PLL. In past years, we have created a lot of scripting for design, verification, and lab analysis of the ADPLL such that we are able to transfer a significant verification package to our customers. This really helps to reduce design and verification time of ADPLLs. This aspect has been a point of concern for productizing ADPLLs in the past but is now well addressed. The road to smaller nodes is wide open.”

“We are proud that we have developed the low-power ADPLL with imec,” commented Isao Matsumoto, director, LSI Production Headquarters/LSI Product Development Headquarters at ROHM, in a press release. The plan is to develop an RF transceiver with the ADPLL and integrate ROHM’s ultra-low power sensors and micro controllers into a “sensor edge” module. “We hope they will be leaders of the IoT market,” he concluded.

Reference

- Nelson, R., “Technologists tout IoT success,” EE-Evaluation Engineering, September 2015, p. 6.