BAS Interoperability Speeds Up Smart-Building Adoption

As a relatively open environment, the internet can be seen as a benevolent framework of interconnectivity. Conversely, its precocious offspring, the Internet of Things (IoT), is a disruptive force for change, particularly when the IoT’s flows of data from connected sensors, actuators, meters and controllers meet up with older legacy systems in long-established industries.

That’s because industries have been putting data to work for decades, and vertical sectors have developed their own ways of acquiring, communicating, and utilizing data. Examples of established vertical-specific standards include CAN for automotive, BACnet and LonWorks for building automation, and Profibus for industrial automation. Within each of these vertical ecosystems, it gets even more complex.

Take building automation, where there are specific protocols for HVAC, energy use monitoring, security, lighting control, and others. Now, the IoT is asking those disparate systems to share their data in a format it can understand, which is disruptive because it simultaneously highlights the value in sharing data and the challenges involved in doing so.

Building automation systems (BAS) are one example of how this is happening right now. Building automation has always been closely aligned with monitoring of assets and energy usage to automate operations and maintenance. More recently, the use of energy-management information systems (EMIS) in association with a BAS allow organizations to not only monitor their own energy consumption, but feed their data into larger networks that can compare high-level trends in energy usage to increase efficiencies.

The benefits that come from building automation are significant. Thus, it’s entirely understandable that owners and operators of buildings that feature BAS systems are keen to extend their infrastructures to integrate more functionality—especially those that provide preventive and optimization measures and reduce op-ex.

At a local level, such integration may be as simple as adding more sensors, actuators, and meters. However, the challenge comes from harnessing the small data provided by these devices into big data that can be shared with other equipment, enterprise systems, and cloud services used for wider purposes beyond simply more automated systems. For instance, the integration of the IoT—in the form of sensor and cloud technologies—with BAS systems can push building operations from a reactive to proactive mode, improving cost efficiencies, tenant satisfaction, and safety.

Predictive Analytics and Data Visualization

One of the reasons why data is in such great demand in industry is that machine-learning and artificial-intelligence algorithms running in the cloud can use this data to predict when equipment is likely to fail or otherwise reach end-of-life. These predictive analytics rely heavily on data that’s both current and accurate.

Using new and old forms of data to predict future events in this way forms part of a data-visualization approach to building maintenance and optimization. It allows operators and machines to see where and when a problem may occur, avoiding costly downtime in a production environment, or potential health hazards in the case of an office building or factory floor. Such an approach enables building owners to optimize usage of space based on past patterns of occupancy. It also informs facility managers of wasted energy based on historical statistics, or recommends optimal settings based on weather patterns outside and demand patterns inside.

Predictive analytics and data visualization are marquee IoT services that cloud providers, such as IBM’s Watson and Microsoft’s Azure, are unleashing to the industrial world. As such, they’re not part of the traditional BAS offering. However, to take advantage of the possibilities presented by these new services requires access to the data produced by the building-management system and the context behind that data.

Today, a typically closed system like a BAS can’t readily provide access to this data and its context to services outside of its infrastructure. What’s needed is a way to build a bridge between legacy building systems and the cloud services that can analyze and interpret the data to gain valuable new insights.

Edge Servers Provide the Interface

An industrial edge server offers an effective connection between an existing BAS and new advanced features such as predictive analytics, data visualization, and remote management.

An edge server provides a way of extending a legacy system through support for a wide range of standard interfaces and protocols, with common device drivers already integrated into the system. It also supports services needed for automation that run on the edge, such as device managers, schedulers, or alarm triggers. This creates an open interface to what integrators might call the “south side,” which are the devices and controllers used in a BAS system itself. On the “north side” of this scenario are the internet and cloud-based services.

An edge server can effectively deliver an end-to-end solution through an interoperability layer that provides translation between the two domains. It provides an interface and portal for additional services both on the north side and the south side of the network.

SmartServer IoT for BAS

Putting a server at the edge of the network will bring IT and legacy industrial systems together. To the BAS, the server will appear to be part of the local management system, accessing data from all parts of the network, and using that data to make inter-system decisions and recommend actions. To the wider internet and the IoT in particular, the server will appear to be a part of the larger network, able to communicate seamlessly with remote services and share data on an unprecedented level.

For example, an edge server developed by Adesto, called SmartServer IoT, includes device drivers for BAS modules and support for all popular IoT protocols used by the BAS industry. It could also support emerging communications protocols that aren’t BAS-specific, like Zigbee or Wi-Fi, with the addition of simple drivers. In addition, APIs included in the server are used to implement two of the most widely adopted web-based technologies now being used to communicate with the edge: REST and MQTT.

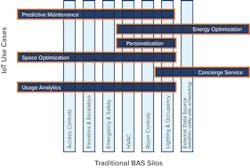

Silos of automation in traditional BAS systems should connect with each other and with external data sources to realize IoT-enabled smart-buildings use cases.

The use of APIs will be critical in bridging the operational and IT domains in an open and scalable way. Existing BAS equipment suppliers are effectively tied into their own closed systems, making it difficult for IT developers to access them (see figure). By using standard web interfaces to access IoT data in BAS implementations, SmartServer IoT effectively lowers the barriers to extending legacy systems and building more flexible building-automation solutions.

Another key technology enabling the SmartServer IoT is the IoT Access Protocol (IAP), which provides a translation layer between the web and the building’s hardware. IAP allows data and its meaning to flow freely to and from the device itself. Perhaps more importantly, it gives IT developers the tools they need to manage southbound operational systems with software, without having to decipher a multitude of different BAS protocols. System designers can access devices and actionable data, as well as develop applications that can execute both at the edge and in the cloud.

End-to-End Open Systems Help Accelerate Smart-Building Integration

In today’s market, there are two main types of edge server solutions: closed field servers from building and industrial automation vendors, and open industrial gateways from IT vendors.

What’s the difference? Closed field servers usually come with built-in support only for protocols and devices that are compatible with the offerings of the building-automation vendor. These proprietary systems can lead to single-vendor lock-in that limits openness and extensibility to products outside of the vendor ecosystem.

Open-box industrial gateways don’t restrict users to a limited ecosystem of offerings. However, these platforms are essentially bare-metal Linux or Windows machines. Developing a fully functioning edge server with the necessary protocols and interfaces for building- and industrial-automation applications will take extensive software development and testing.

An edge server like SmartServer IoT unlocks the closed ecosystems of proprietary technologies and removes the need to develop protocols and interfaces from scratch for a wide-open system. The server’s “bridge” combines the full-featured, pre-integrated, out-of-the-box functionality of building and industrial systems with flexible, extensible connections to emerging IoT networks and cloud services.

In other words, adding such an edge server to existing management infrastructure provides an efficient way of gaining open north-bound interfaces for internet connectivity, while its embedded technology helps developers create, share, and run southbound applications both locally and remotely.

Apurba Pradhan is VP of Marketing and Products for Adesto Technologies.