Circuit Protection Device Manufacturer Sees Opportunities in Emerging Trends

Activation steps of MHP device

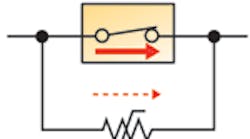

RTP device

Industry Trends

From our perspective as a high-tech components manufacturer, we see the electronics industry being impacted in 2012 by two events that occurred in 2011. First, the natural disaster in Thailand caused supply shortages in an industry that had already begun reducing channel inventories. Second, the downward revisions in GDP that arose from sovereign debt concerns and China slowing its growth to combat inflation have raised uncertainty in future market demand.

The flooding in Thailand, which has resulted in a shortage of components in the hard disc drive sector and affected a broad base of component manufacturers, is the latest challenge to affect the industry. These events have made it clear that, in the long term, manufacturers will emphasize the need for multiple sources of components to be better prepared to survive these natural disasters.

Looking forward to 2012, one challenge to component manufacturers will be working in an industry where the largest customers will demand a diverse supply base, which means having second sources even for highly differentiated products. And, from TE Circuit Protection’s standpoint, we clearly understand the need to continue developing products that address new technologies and emerging trends in order to remain a valued partner. Our recent launches of innovative new products are already reaping rewards and we expect continued success as market acceptance increases.

Circuit Protection

TE Circuit Protection devices are found in countless products we use every day, from smart phones and vehicles to televisions and air conditioning units. To date, billions of TE Circuit Protection devices have been integrated into electronic products in the automotive, multimedia, telecom, portable device, appliance and lighting markets—helping protect them from damage caused by overheating, overvoltage and overcurrent faults.

In 2011, we began seeing revenue from two new technology platforms we introduced at the end of 2010, the MHP (metal hybrid PPTC) device and the RTP (reflowable thermal protector) device. These products were built on a tradition of combining our materials expertise with our collaborative work with OEMs.

The MHP device addresses the trend of using smaller, lighter weight, and higher power Li-ion batteries, which, in turn, has created the need for cost-effective, robust circuit protection devices that enhance battery safety in end-products. The resettable MHP device offers a much needed solution by providing excellent arc suppression characteristics compared to standard breaker devices that must limit the number of switching cycles, since arcing between contacts may damage them.

By combining a PPTC (polymeric positive temperature coefficient) device and a bimetal breaker, the MHP device exemplifies how we utilize our existing technologies to develop pioneering products. We first introduced the PPTC device as the original PolySwitch product in the early 1980s when we were Raychem Circuit Protection. Today, with the emergence of international standards that mandate resettable circuit protection, PPTC technology is specified as an appropriate solution. The MHP device offers designers the most important benefits of both bimetal and PPTC technology. This combination helps provide resettable overcurrent protection; utilizing the low resistance of the PPTC device to help prevent arcing at higher currents while also heating the bimetal to keep it open and in a latched position. Figure 1 illustrates the activation steps of the MHP device.

Although initially developed to help protect high-rate discharge battery packs for power tools, the MHP device can be used to help protect lithium-ion battery applications such as e-bikes.

The RTP device was developed to address the demanding needs of our top OEM customers. The simplified SMD (surface mount device) package of this thermal protection device enables customers to meet stringent safety requirements, while minimizing the assembly costs of their applications. Rather than simply providing a replacement part, the RTP device offers a solution that adds real value to our customers and solves a problem that traditional thermal protection devices were unable to deliver. Since its introduction, the RTP device has been well received and continues to grow in popularity as people learn more about it. We have seen revenues increase as our customers come to understand its unique benefits over existing solutions.

Before the introduction of the RTP device, manufacturers needed to employ larger, more costly approaches for thermal protection of power components, such as silicon and custom solutions, thermal cut offs, heavy heat sinks and relays. TE Circuit Protection developed the RTP device in response to the needs of vehicle manufacturers that were looking for a surface-mount thermal protection device that could handle the high currents found in harsh automotive environments ( >5-10A).

With applications continually moving towards more compact surface mount designs, the major limitations of traditional thermal protection devices are that they are not available in surface mount configurations and require costly manual application processes. The RTP device is a surface mount device, which can withstand up to three reflow passes with peak temperatures of 260°C; and yet, in the field, will open when it detects temperatures above 200°C.

The device’s thermal sensitivity is beneficial since, in some cases, damaged power components may not generate a dead short circuit overcurrent condition, but instead may create a resistive short that cannot be opened by a traditional fuse. The RTP device helps prevent damage caused by both. As shown in Figure 2, when the RTP device is placed in series on the power line in close proximity to the FET, it tracks the FET temperature and opens the circuit before a slow thermal runaway condition can generate an undesirable thermal condition on the board.

Current customers are mainly automotive manufacturers, where power component failure is a common problem. However, as market awareness grows, and we expand on the product family we expect the RTP device will be used in many types of applications, including telecom, industrial and lighting products.

Looking Ahead

The increasing amount of electronics in automobiles is creating the need for more and new kinds of circuit protection solutions. Likewise, electric vehicles are growing in popularity and will require robust circuit protection; not just for the batteries and high voltage power systems but for charging stations, as well.

Renewable energy is becoming more affordable. As solar and wind power solutions enter the home and small business, there is a need for new kinds of solutions to protect against failure of the batteries, as well as facilitating quick and safe disconnect of the high power connections in the system. Energy-efficient lighting—especially LED technology—is another growing trend, and these components require protection against thermal events and surges to optimize performance and lifecycle.

The proliferation of ultra-slim, smart mobile appliances with increased power densities, faster processors, and extended battery life is another megatrend that presents many opportunities for TE Circuit Protection. Extremely slim sizes, increased sensitivity, and faster connector speeds (i.e., Thunderbolt technology) will make protection solutions even more challenging, but offer exciting new opportunities in 2012.