As governments around the globe look to cut costs, defence budgets are under fire. This pressure has manifested in the specification and procurement of components for electronic systems, especially for those applications that are not mission critical.

Related Articles

- The Military FACEs Its High-Tech Future

- Test For Military Embodies "Mission Critical" Status

- DoD Budget Cuts Reshape Military Electronic Design

Military qualified components are expensive not only because of their rigorous qualification processes and extended test cycles, often repeated at extreme parametric limits and under harsh environmental conditions, but also because they have to comply with strict rules set by national or international bodies that define quality and other performance or manufacturing criteria.

Any change in a device’s specification, or the materials used to produce it, will usually require a complete requalification of the component or at the very least customer acceptance of a detailed change notification. Add to this the need to maintain availability of mil-qualified devices for 10 years or more, and the arguments supporting an alternative approach can be readily appreciated.

COTS (commercial off-the-shelf) is now a familiar name for the initiative that was devised to offer designers of military and aerospace electronics systems access to low-cost alternatives to full mil-spec parts. As the acronym implies, these commercial products have not been specifically designed or qualified for the military market.

To meet potentially more demanding equipment performance requirements, though, manufacturers may not have specified these components for operation over wider temperature ranges or with greater tolerance in respect of electrical parameters such as supply voltage.

Designers who need to meet tougher operating conditions, such as high humidity or extremes of shock and vibration, are calling for more ruggedized versions of COTS products. Such options still need to satisfy the “off-the-shelf” criteria of being a catalogue product but may be selected from a range qualified for other applications, such as automotive components conforming to AEC-Q200, and applied using more conservative design rules. These parts, which still avoid the need for high-reliability qualification, are now being referred to as COTS+.

This file type includes high resolution graphics and schematics when applicable.

Standards And Qualification Levels

Given the size and significance of its defence industry, particularly in the post-war and cold-war era, it is not surprising to find that the United States Department of Defense (DoD) had a leading role in defining standards for the testing of electronic components used in military systems.

The importance of dependable components was also vital in the exploration of space, from the Apollo moon landings and Space Shuttle missions through NASA’s current involvement in the International Space Station. Today’s commercial aircraft and satellite businesses still benefit from the “peace dividend” of this technology and the standards that were developed by the DoD and NASA.

Key relevant standards to be aware of, including those from other bodies such as the International Organization for Standardization (ISO), include:

• MIL-STD-883 defines uniform methods, controls, and procedures for testing microelectronic components for use in military and aerospace systems. It covers environmental and mechanical tests in addition to electrical tests for both analogue and digital devices. Its procedures deal with parametric control, limit testing, quality and conformance, lot acceptance, failure analysis, and destructive physical analysis (DPA).

• MIL-STD-202 is another set of test methods comprising three classes of test, covering environmental, physical, and electrical characteristics. These methods are often quoted in respect of stress testing of devices, for example at 85% relative humidity and at 85°C.

• ISO 9000 standards address various aspects of quality management and provide an effective quality assurance system, which helps companies ensure their products consistently meet customer requirements. Many equipment manufacturers require their component suppliers to be ISO 9001 certified.

• AEC-Q200 is a standard from the Automotive Electronics Council that provides for the qualification of passive electronic components to meet the reliability requirements of the automotive industry. This includes high-temperature operation, resistance to high-humidity and shock, and related durability criteria. The AEC’s Q100 and Q101 standards similarly cover integrated circuits and discrete semiconductors.

• MIL-DTL-38999 is one of a series of MIL-DTL (formerly MIL-C) standards that relate to electrical connectors and detail the specific configuration of a connector in terms of its construction, dimensions, connecting method, and contact type and covering its electrical and environmental performance.

• MIL-PRF-55365 is a specification for tantalum dielectric chip capacitors that defines their performance in terms of voltage, capacitance, capacitance tolerance, and quality level but also includes such criteria as termination finish and optional surge current testing.

• MIL-PRF-55681 is similar to MIL-PRF-55365 but defines performance requirements for ceramic dielectric chip capacitors.

• MIL-DTL-3786 and its subsidiary specifications cover rotary switches and aims to ensure that switches of a particular style meet the envelope size and dimensional, environmental, and electrical requirements for that style.

COTS Components From Leading Manufacturers

Amphenol’s COTS 38999 series of PC tail connectors provides full mating compatibility with standard D38999 plugs and is specified for operation from –55°C to 125°C. The series conforms to the electrical characteristics and mechanical dimensions that would apply to full mil-qualified parts and is manufactured using high-quality materials: aluminium shells, neoprene inserts, gold-plated copper alloy contacts, and a silicone rubber gasket. Connectors are ruggedized using RoHS-compliant (Restrictions on Hazardous Substances) corrosion-resistant plating, with contacts guaranteed for 500 mating cycles and meeting the IP67 standard for dust/moisture ingress.

TE Connectivity produces ruggedized versions of its modular, lightweight, high-speed board-to-board interconnect system, which targets VPX applications and the connection between backplane and daughter cards in rack-mount equipment and VMEbus-based systems. Its MULTIGIG RT 2-R series provides enhanced alignment performance with a stainless steel guide pin on the backplane and a machined guide socket on the daughter card (Fig. 1). Electrical contact is improved with extended pads on the daughter card and quad redundant contacts in the backplane connector.

Grayhill is a leading provider of electromechanical components for the defence and aerospace industries, including rotary encoders and pushbutton and rotary switches. Rotary devices such as the 26 series encoders and 77 series switches employ shaft and panel seals for use in harsh environments, resisting dust, moisture, salt spray, and even complete immersion to military standards (Fig. 2). Its rotary switches have high torque and feature push and pull-to-turn functions to avoid accidental actuation while gold-plated electrical switch contacts ensure long operational life, up to 100,000 cycles.

AVX manufactures high-reliability tantalum chip capacitors to various conformance levels from COTS+ all the way through the various MIL-PRF-55365 grades, including “T” Level, to the SRC9000 Space Level release. These capacitors also comply with UL94V-0 for flame retardancy.

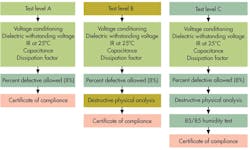

Kemet uses its experience and knowledge of high-reliability test regimes and requirements to offer COTS products from the same components that are used to source its mil-spec products. For example, its COTS-grade Multilayer Ceramic Chip Capacitors are subject to the same voltage conditioning and post-electrical testing as defined by MIL-PRF-55681. For enhanced reliability, Kemet offers additional test options and conformance certification (Fig. 3). Level A involves statistical lot defect testing, level B adds destructive physical testing, and level C adds 85/85 humidity testing.

Conclusion

Understanding the multiplicity and complexity of the standards that apply to mil-spec components is in itself a daunting challenge. It’s not surprising, then, that implementing these qualification processes and testing regimes contributes to substantial additional costs.

For military and aerospace applications that are not mission critical, and where fully compliant parts are not mandated, it makes economic sense to utilise COTS parts. And even for applications subject to harsher environmental operating conditions, it should be possible to utilise suitably ruggedized versions of COTS designs. This practise of using COTS and COTS+ parts is now commonplace and supported by products from leading electronic component manufacturers.

Adam Chidley is the European product manager at Avnet Abacus. For the past eight years, he has worked at Avnet with line responsibility for several key suppliers and technologies across the group. His previous experience was in contract manufacturing and for component manufacturers, where he gained a broad understanding of this market from concept to production.