The Chemical Tests of the Future Could Move onto Chips

Marcel Zevenbergen imagines chemical sensors that are the size of a fingernail, measure chloride levels in a farm’s water supply, and stream data wirelessly for months. These are not the cattail-shaped electrodes and analytical machines that scientists have traditionally used to measure chemicals in fluid.

Zevenbergen is a senior researcher at the Holst Centre, a Dutch microelectronics lab where engineers are trying to shrink such chemical sensors down into silicon chips. These devices largely missed out on the falling cost and dimensions of other sensors that measure things like pressure or temperature.

Founded in 2005, the Holst Centre is the result of a partnership between the Netherlands Organization for Applied Scientific Research and Imec, a leading microelectronics research center in Belgium. It is trying to bring the same transformative advances to sensors as Imec has done with some of the world’s smallest and most sophisticated computer chips.

Today, that goal is shared by many other researchers in fields ranging from industrial control to healthcare. Just last month, scientists from the University of California, Santa Cruz, published a paper that described a lab-on-a-chip that helps screen blood for cancer. The tiny system is faster and requires less fluid than traditional lab equipment, they said.

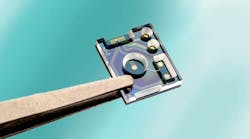

At the IEEE International Electron Devices Meeting last month in San Francisco, Zevenbergen and his colleagues showed a new chemical sensor that dwarfs other devices built with ion-selective membranes, the gold standard for measuring chemicals in fluid. The big news is that it's small enough to be integrated in an SoC with computers and wireless transmitters.

The advance could make it possible for the tiny parts to have the same lifespan and accuracy as ion-selective sensors, which contain electrodes that react with ions floating in fluids, generating an electric current based on the reaction's intensity. That would make them useful for large networks of wireless sensors on farms, hospitals, or factories.

In an interview, Zevenbergen said that the challenge has been slowing how fast the sensors' electrodes break down - something that causes their readings to drift. The sensors typically only last three to six months before they must be cleaned, recalibrated, or replaced. Shrinking the electrodes to a chip's scale has meant that they break down faster.

The problem is with the reference electrode, which connects to the membranes that interact with chemicals dissolved in the fluid to measure the concentration. A voltage created from the chemical reaction at the membrane is compared to the behavior of the reference electrode. The electrode can also be compromised by temperature, light, or contaminants.

Typically, the reference electrode contains a reservoir filled with around 10 milliliters of electrolyte that slowly leak out of the sensor and cause drift. But the Holst researchers carved a tiny channel in the reference electrode to better hold onto the electrolyte. The other benefit: the sensor only needs 10 microliters of electrolyte fluid.

The “microfluidic channel” acts like a contact between the reference electrode and iridium oxide and silver chloride membranes, which measure for acidity and chloride, respectively. Hardly anything will slosh out of the channel, Zevenbergen said, allowing the sensor readings to remain stable as long as larger devices.

The result is that the devices can be fabricated on silicon substrates much smaller than previously thought. They also have the same or better accuracy, said Zevenbergen. Potentially, the sensors can be produced at lower costs, too.

Holst researchers are far from the only ones trying to put fluid sensors onto silicon. In 2014, researchers at the Vienna University of Technology made a prototype sensor using miniaturized laser technology to cast infrared light into fluid. The sensor measured chemicals by detecting the presence of molecules – like oxygen in a newborn’s blood – that absorb the light.

More recently, electrical engineer Anurahda Agarwal and MIT researchers created glass lenses that emit infrared light to measure specific chemicals. Such innovations, she said, could enable applications like minimizing waste in oil processing, quality monitoring in a water purification plant, and inspecting food for freshness.

Holst’s sensors are still in the early stages. Zevenberg said that he was working with several companies on the pre-competitive research, though declined to name names. But, he said, that the new advance could have wide implications beyond chloride and acidity sensors.

One idea, he said, was to integrate sodium sensors into vests that detect symptoms of dehydration in an athlete’s sweat. Another is using the sensors on farmland to measure soil nutrients.