This file type includes high-resolution graphics and schematics when applicable.

Most commonly used electronic devices have some type of Universal Serial Bus (USB) port. These ports come in Micro, Mini and Type-A connector formats and can support different USB standards such 2.0 or more recently, 3.1. USB Type-C is the next leap forward for these ports, featuring higher speeds and better power delivery. This more advanced connecter solves all of the problems presented by its predecessors. Type-C can handle high-speed data, video and large amounts of power. With the expanded capabilities of Type-C, consumers will only need to use Type-C cables to charge, stream video, or transfer data—tasks that took a variety of cables. Manufacturers will need to provide and develop Type-C ports on their devices to support different purposes.

Type-C technology’s versatility comes at a cost, because USB’s once-simple inner workings of cables, ports, dongles, and hubs have been replaced by more complex embedded components. A seemingly straightforward HDMI-to-Type-C cable is difficult to design due to the required embedded devices.

Two main complications arise when developing Type-C solutions. The first involves handling its wide range of power. The second is to avoid communication failures that can occur due to the increase in supported communication standards.

When two devices are connected, the USB Power Delivery (PD) protocol is initiated. The process involves a negotiation among the amount of power delivered, and who will be the provider and consumer of that power. Since this communication requires detecting, reading, and processing analog and digital signals, it needs microcontroller functionality provided by an embedded MCU within the host port, cable, or dongle. Failures can occur when devices or hosts don’t support each other and can’t establish communication. They’re detected and then communicated to the host and require further MCU functionality.

USB Type-C makes life easier for end users by reducing cables and ensuring that devices work together. Because of its inherent complexity, Type-C can also pose design challenges for developers.

What is USB Type-C?

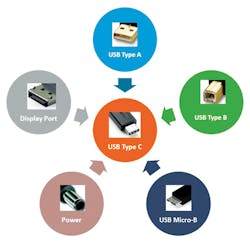

Many types of USB ports and cables are available these days, including Mini, Micro, Type-A and Type-B. Such variety can be confusing because a mobile phone has a different port than a laptop, which has a different port than a digital camera.

USB Type-C condenses most connections to one standard, covering all devices and enhancing usability. This convergence of all USB ports and cables (Fig. 1) can also handle charging as well as video. Furthermore, USB Type-C supports multiple protocols and is backward-compatible with USB 2.0. Almost all accessories, including monitors, headphones, chargers, and keyboards, are able to use USB Type-C to communicate with computers, tablets, and smartphones.

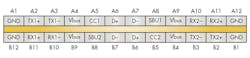

USB Type-C port and cable layouts are shown in Figures 2 and 3. Flipping the plug doesn’t cause any problems due to the symmetrical design of the signals in the receptacle port. The USB 3.1 SuperSpeed TX/RX, Vbus, GND, and other pins are connected correctly regardless of the orientation of the plug and receptacle. From a user standpoint, this approach is an upgrade from Type-A ports, as the Type-C cable can be inserted in either direction.

USB Type-C is versatile and user-friendly, but this ease of use increases the internal complexity for devices that employ the technology. It has increased power capability (delivering up to 100 W of power to charge a high-current device), but that creates issues for devices that don’t require so much power. This is where the PD protocol is useful. PD ensures the appropriate range of power is delivered or sourced from any connected devices.

USB Type-C Terminology

Before discussing USB Type-C, it’s important to distinguish between the device, the host, the power supplier (source), and the power receiver (sink). The host isn’t always the source; therefore, the terms can’t be used interchangeably. Hosts initiate all communication and devices respond. Typically, the host is the downstream-facing port (DFP), and the device is the upstream- facing port (UFP). If two hosts are connected, they can act as a dual-role port (DRP) to switch between acting as a host and a device. For example, when a keyboard is connected to a laptop, the keyboard is the UFP and sink, while the laptop is the DFP and source.

Power Delivery

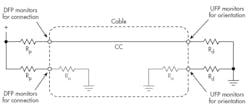

The initial power-delivery agreement between connected devices is executed through a series of resistors acting as voltage dividers on CC wires when a Type-C plug is inserted into the receptacle. Figure 4 shows a typical USB Type-C channel line topology.

Since the CC line in the plug is either connected to CC1 or CC2 in the receptacle, the receptacle determines the orientation of the plug by simply measuring the voltages on both CC1 and CC2 lines. The different values of the pull-up resistors communicate the amount of current the source is able to supply, and establishes what will be the UFP and the DFP. The power consumer doesn’t have a way to indicate how much current it sinks through different pull-down resistor values; it has to dynamically adapt its load to match the maximum current available from the provider.

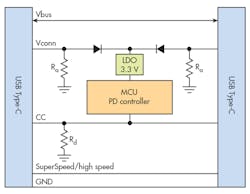

To read the voltage divider correctly, both devices need an analog processing unit, usually in the form of an accurate analog-to-digital converter (ADC) within an MCU. The ADC measures the voltage on the CC line continuously to monitor the connection between the plug and the receptacle. The MCU, known as the PD controller, handles the complete physical layer and upper layer protocol. It negotiates the power being delivered or received. For simple Type-C applications, the power negotiation stops with the resistors. For a more adaptable design, though, the devices can agree on a different setup by communicating over the CC line.

Once the plug orientation and initial power are decided, the devices use the CC line to communicate with each other. Using this line, the devices can agree on different levels of power and designate the sink or source, enabling real-time power-delivery adaptation. CC line communication is also used to announce which type of communication will be used. As previously stated, USB Type-C can communicate on the high-speed lines, USB 2.0, and other lines. The devices announce which of these lines can be used via the CC line. However, not all devices support all communication protocols.

Failure Notification

A failure occurs if the two connected devices don't support one another. For example, a failure would occur if a monitor, which can only receive video from a host, is connected to a host that's unable to support supply video data. If this happens, the host will remain unaware of the failure because communication can't be established.

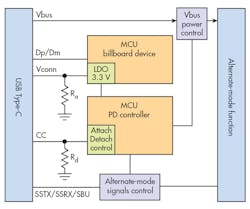

In light of this scenario, the USB Type-C standard demands an embedded device on the monitor or device side to act as a failsafe known as a “Billboard” device. The Billboard device signals to the host through the USB 2.0 standard on the D+ and D- lines that communication cannot be established. The host can then notify the user that the two devices are incompatible. Billboard devices are typically MCUs, which may be the same as the PD controller.

Type-C Cables and Adapters

Users who wish to use older peripherals that don’t support USB Type-C need to incorporate converting cables or dongles. There are multiple cases to account for, the first being the simple USB 2.0 to Type-C. Because USB 2.0 doesn’t support higher speeds, and doesn’t require more than 5 V or 3 A on Vbus, the cable can simply route D+/D-, Vbus, and GND to the connectors. A Type-C to Type-C cable, a dongle that converts USB 3.0/1 to Type-C, or one that requires more than 5 V or 3 A on Vbus, is more difficult to design.

In these cases, the dongle becomes part of the power negotiation between the two devices, requiring the cable or dongle to have an embedded PD controller. The PD controller is initially powered through Vbus set at 5 V or the Vconn line. It then negotiates with the host to set an agreed upon power level on the Vbus line.

Figure 5 shows an electronically marked cable assembly, or EMCA example, for connecting two Type-C devices. The PD controller can be powered by Vconn 1 or Vconn 2. The EMCA will advertise its maximum power capabilities on the CC line, and the source will adapt to suit.

Type-C Adapter with Alternate Mode

An alternate mode is the functional extension of the Type-C interface, which allows DisplayPort, PCIe, or other communications protocols to use the USB 3.1 SuperSpeed lines. The alternate mode is entered when connecting the adapter to a compatible host.

A dongle that supports the alternate mode requires extra precautions and embedded devices. The dongle must inform the host if it was unable to enter the alternate mode to avoid a silent failure. It accomplishes this task through the Billboard device, and the USB Type-C PD standard mandates that any alternate-mode accessory implement a Billboard device.

Figure 6 shows a cable that converts a legacy video port into Type-C. If the Type-C device doesn’t support the legacy video format, the Billboard device will be informed by the PD controller, and will, in turn, inform the Type-C device of the failure.

Docking Station or Hub

A more complex example than display/Type-C to Type-C is a docking station or hub that must support charging many devices. The hub can be a combination of multiple Type-C or Type-A ports, HDMI, and PCIe. This hub requires multiple embedded devices to successfully support connected devices. Each port, depending on what device is connected, will need different amounts of power. To account for this, each port may require a PD device.

Any video ports, such as display, VGA, or HDMI, will need a Billboard device. In addition, the hub requires a device to control traffic to the host. This remains largely unchanged from the Type-A hubs, because you must prevent collisions on the lines and ensure that only one device is communicating to the host at one time. It’s clear that the previously simple hub now requires a more complex and demanding design.

USB Type-C Solutions

All of this added design complexity needn’t fall solely on developers. USB device suppliers like Silicon Labs provide development boards, PD libraries, Billboard source code, and example code aimed at dongles, docking stations, and device ports. Developers can greatly reduce USB Type-C development time and effort by using these tools when developing new Type-C devices.

Development boards (Fig. 7) are now available that implement a Vesa DisplayPort alternate-mode adapter with charging capability. Developing such a device increases the capability of a single Type-C port on a host by allowing power (charging) and video to come through one port.

The board shown in Figure 7 features two PD controllers, one for each port, and a Billboard device to accompany the DisplayPort. The reference design handles switching to alternate mode, charging, informing the host of a failure, and ensuring correct power delivery to the display port and host. Using a development board like this, along with supplied firmware, is less painful and faster than creating a new platform and writing firmware from scratch. With such development tools, manufacturers and suppliers can quickly deliver a Type-C solution with enhanced functionality.

Conclusion

USB Type-C is the standard of the future. The days of digging through a drawer looking for the correct conversion or cable ends are over. Going forward, choosing a cable will involve deciding whether the end is a plug or receptacle, and whether it can handle higher amounts of power. Smartphones, tablets, and laptops that have only Type-C ports are already on the market, and these pioneering devices are just the start.

Type-C requires embedded devices and firmware to handle vast functionalities, which puts a strain on developers and manufacturers as they migrate their devices. Fortunately, embedded developers can turn to USB Type-C reference designs, libraries, firmware, and support teams dedicated to simplifying Type-C requirements for a wide array of applications.

Looking for parts? Go to SourceESB.