The Future of Electronics: Rigid vs. Flexible Semiconductors

What you'll learn:

- Differences between rigid and flexible semiconductors.

- Making the "Internet of Everything" happen.

- Quick and easy customization with flexible semiconductors.

Semiconductors have long been a critical enabler in everything from smartphones to industrial machines, underpinning digital transformation, boosting efficiency and productivity, and driving new and exciting consumer experiences.

To date, rigid silicon chips have dominated the semiconductor market. However, as innovators push the boundaries of the possible, new flexible semiconductors—based on advanced materials such as metal oxides or organic semiconductors—are emerging as a complementary technology. They pave the way to new use cases in diverse sectors from industrial and healthcare to consumer electronics.

But what are the key differences? And as ubiquitous intelligence becomes a reality, how do these complementary technologies measure up?

Rigid vs. Flexible Semiconductors

Rigid silicon semiconductors excel in processing power, making them indispensable for high-performance tasks like powering computers and smartphones, AI, and autonomous systems. Designed for robustness, they offer proven, long-term reliability—a must for mission-critical applications where failure isn’t an option, such as aerospace, automotive, and telecommunications.

But this performance comes at the expense of flexibility, both literally and figuratively. The long lead times and high costs associated with silicon chip production often result in overly complex specifications, creating chips that are ready for anything rather than tailored to a specific task.

This is, of course, entirely logical: If chips are likely to take months, or even years, to reach the point of delivery, then it makes sense to make them fit for a wide range of use cases, irrespective of immediate need. But for some use cases, that’s like using a sledgehammer to crack a nut. While silicon chips deliver high performance, they typically do it at a high cost and with significant environmental impact.

And what of the form factor? Rigid semiconductors absolutely make sense for structured, flat designs like smartphones and computers. But as the Internet of Things (IoT) becomes an Internet of Everything (IoE)—a long-promised brave new world where intelligence is embedded directly into everyday objects—flexibility can open up new opportunities for adding intelligence almost anywhere.

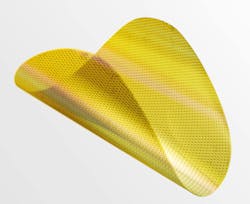

Since they’re lightweight, thin, and bendable, flexible semiconductors (Fig. 1) can integrate seamlessly into items with curved or irregular surfaces. Embedded directly into packaging, they’re imperceptible to the touch. They don’t encroach on product branding, can’t be covered or replaced, and are robust enough to withstand the rigors of transportation. And their comparatively low cost makes it viable to bring intelligence at scale to high-volume products, making insights available wherever they’re needed.

An Internet of Everything

While rigid silicon chips will no doubt dominate high-powered applications for some time to come, flexible semiconductors introduce a new paradigm: Intelligence can be added where conventional electronics would not be cost-effective or even possible.

This is predominantly due to their fabrication, which is more agile than standard semiconductor production and carries a significantly lower environmental overhead. It also allows for end-to-end production at a single site. As a result, production is significantly faster—typically just a few weeks, compared to the months of standard chip production.

Rigid silicon semiconductors have a highly complex preparation process with hundreds of steps, many at extremely high temperatures. A large part of this is required to prepare the silicon ingot, from which the wafer is sliced before being etched and diced into chips. At the other end of the scale, flexible semiconductors using thin-film technology have just 30 process steps—most of which occur at less than 200°C—and use a simple coating of polyimide for wafer preparation.

Naturally, this pared-down process consumes less energy, less water, and fewer harmful chemicals, driving down the carbon impact of production. It also significantly reduces non-recurring engineering costs. These factors alone make this type of semiconductor more suited to mass-market applications. However, another benefit of rapid production is the opportunity it creates for fast and affordable customization.

Customizable Intelligence

Customization in rigid semiconductors can be costly and time-consuming but delivers unparalleled performance and efficiency.

By contrast, customizing flexible semiconductor designs (Fig. 2) is quick and easy. Designs are fit for purpose and typically less complex, with tradeoffs in performance accepted for improved cost, versatility, and adaptability. This makes the resulting chips ideal for application-specific workloads—particularly in edge IoE use cases.

In fact, the potential for flexible chips is vast. From smart labels on food packaging that monitor freshness to flexible sensors embedded in athletic apparel to track biometrics, they enable a future where electronics are seamlessly integrated into the world around us.

Their malleable form factor makes them ideal for use in smart medical patches that are cost-effective and comfortable to wear. These could enable wound monitoring—alerting clinicians to signs of deterioration by moisture/leak detection or changes in temperature, pressure, or pH—or detect heartbeat irregularities that may foreshadow more serious coronary events.

Embedded into product packaging, they facilitate smooth, interactive consumer engagement that’s accessible with a single tap of a smartphone. Discreet and protected, they can give instant access to dynamic, personalized content, helping to drive loyalty and make every touchpoint a richer experience.

Looking to the future, they could provide new, powerful ways to interact with our environment, enabling monitoring, detection, and autonomous decision-making as part of sensor swarms—clusters of interconnected sensors working collaboratively to collect vast amounts of data in real-time. Here, the applications are as diverse as they are impactful, from tracking climate change and monitoring pollution levels to optimizing energy consumption or enhancing traffic management in smart city scenarios.

In virtual- and augmented-reality (VR/AR) applications, they could facilitate increasingly sophisticated remote immersive and interactive experiences embedded into more lightweight, affordable, and user-friendly glasses and headsets, or even electronic skin.

They may even have a role to play in biological computation, where microfluidics and lab-on-a-chip technologies implement operations that have historically required an entire laboratory. This innovation can make scientific research more efficient and cost-effective, but it could also democratize access to advanced diagnostic and analytical tools, potentially transforming healthcare and other fields worldwide.

Complementary Intelligence

In short, rigid and flexible semiconductors play complementary but equally valuable roles in our increasingly connected world. Flexible semiconductors will not replace rigid silicon chips. Rather, they’ll work alongside them, allowing innovators to choose the best chip for the task at hand.

By using flexible chips for low-cost, customizable intelligence, where their rapid production, carbon footprint, and form factor bring advantages, we can free rigid silicon chips, with their heavier carbon footprint, for workloads where power and optimal generalized performance are imperative.

The future of electronics will build on the robust credentials of rigid semiconductors with the low-cost agility of their flexible counterparts, giving innovators endless versatility and the ability to meet their design challenges, however big or small.

About the Author

Richard Price

CTO, Pragmatic Semiconductor

Richard Price has over 25 years of experience in the development and commercialization of a wide range of new technologies based on novel processes, materials, and flexible electronics. He holds a BSc and PhD in Chemistry from the University of Durham. Richard is an inventor/co-inventor of over 25 patent families. He’s a non-executive director at the Henry Royce Institute, the UK’s National Institute for Advanced Materials Research.