Through the Substrate Looking Glass

This video is part of the TechXchanges: Chiplets – Electronic Design Automation Insights and Chip Packaging.

What you’ll learn:

- Why would you want to use a glass substrate?

- What are the current alternatives to a glass substrate?

Chiplets and advanced packaging have been on the cutting-edge of electronic technology for a while, but Intel is changing where it might be headed. Today’s organic substrates, like Ajinomoto build-up film (ABF), are getting some competition from a common material—glass.

Glass has great thermal characteristics. It can be extremely flat, which is useful in chiplet applications, and it has very good mechanical characteristics. Intel is now showing off its glass substrate solution, one that could wind up in shipping devices in a couple years.

I talked with Jim Handy, an analyst at Objective Analysis, about Intel’s latest announcement.

The use of chiplets in system-on-package (SOP) devices is becoming more common, especially when employing the latest transistor node. Mixing technologies in a device using chiplets based on different nodes or technologies allows for more effective designs as well as making construction less expensive. Standard chiplets like high bandwidth memory (HBM) and interconnect standards such as the Universal Chiplet Interconnect Express (UCIe) facilitate heterogeneous integration.

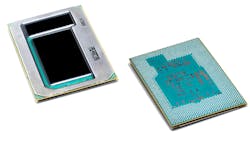

Intel has been producing, but not selling, glass-based devices to test out the technology and production requirements (Fig. 1). So far, the results have been excellent. The glass substrate has half the pattern distortion compared to the competition, and the ultra-low flatness improves depth of focus for the lithography support. This also helps enhance dimensional stability required for extremely tight layer-to-layer interconnect overlays. This, in turn, allows for higher-density connections.

The company has created devices using its latest technology (Fig. 2). The yield with glass is also better as glass substrates can handle higher temperatures. This affects everything from signal routing to power delivery. Integration with components like resistors, capacitors, and inductors is possible, too, due to the higher temperature support.

Intel projects that glass substrates will first target applications that utilize chiplets and large format factor packages. This includes data-center applications where high-density system-on-chip (SoC) solutions are used for CPU core counts in the hundreds and, in the future, thousands of cores. It’s also where large amounts of memory with high-bandwidth connections will benefit applications. Another area where glass substrates may have an advantage is optical connections.

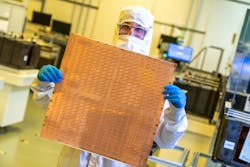

The company has been working on glass-substrate technology for more than a decade. The latest announcement shows off its production capabilities (Fig. 3) as well as where its headed.

Check out more videos/articles in the TechXchanges: Chiplets – Electronic Design Automation Insights and Chip Packaging.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.