What’s the Difference Between DIMM and CAMM?

What you’ll learn:

- What is the Compression Attached Memory Module (CAMM)?

- Why CAMM is different from DIMMs.

- Why CAMM is better than DIMMs.

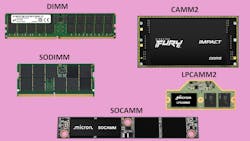

Dual inline memory modules (DIMMs) come in a number of form factors for laptops, desktops, and servers, which is also the target for the new Compression Attached Memory Module (CAMM). DIMMs and CAMMs are typically populated with DRAM, although the form factors have been used for other storage technologies. They come in different form factors that target different applications, and JEDEC provides the standards for both (Fig. 1). Each is also field-replaceable; but, DIMMs can be installed without tools whereas CAMMs are screwed in.

CAMM Pushes the Performance and Capacity Envelope

DIMMs were adopted because they were inexpensive to build and easy to install. The approach worked when memory capacity, thermal design, electrical characteristics, and bandwidth could be handled by the edge connectors. However, advances in processor and memory technology have pushed the envelope in these areas, which is where CAMMs have an edge.

The difference between DIMMs and CAMMs is more apparent when looking at the connectors used with DIMMs and CAMMs (Fig. 2). Two main items stand out. First is the layout of the pins and their connections. The second is how well the modules are connected to the sockets.

DIMMs are typically held in by spring loaded clips, which makes replacement easy. They’re suitable for applications like laptops, where the memory is protected and not subject to extensive shock and vibration, but not for rugged embedded systems. It’s possible to protect DIMMs in these environments, though it’s typically done in a non-standard manner.

The exact differences in performance and capacity vary widely as DIMMs and CAMMs are designed to provide engineers and users with choice. Compatibility with a particular motherboard is usually the determining factor when choosing memory modules.

An example of the improved performance provided by CAMM solutions is Micron’s SOCAMM modules targeting servers. They have 2.5X higher bandwidth at the same capacity when compared to registered DIMMs (RDIMMs) used in servers. These 14- × 90-mm modules are significantly smaller than comparable-capacity RDIMMs. Their first implementation employs LPDDR5X memory chips that consume one-third the power of standard DDR5 RDIMMs.

These SOCAMMs use four 16-die stacks of LPDDR5X memory; thus, a single module has 128-GB capacity. Many of these will find homes in servers—they target servers set up to run artificial-intelligence (AI) applications. Since they will be pushing the envelope, a larger number of them will be a bit warm.

Keep Memory Cool—CAMMs Win

Early DIMMs didn’t require additional thermal considerations, but higher-performance DIMMs run hotter. Though most can still operate without additional cooling options, high-performance DIMMs, like those used for high-end gaming systems, include heatsinks. External cooling fans are an option; liquid cooling tends to be more challenging.

CAMM architecture and standards lend themselves to improved cooling options, including liquid cooling. In many instances, they can operate without it. But when performance goes up, so does the amount of power being pumped into the system, which must be removed or problems will crop up.

Multiple CAMM devices can be supported by a motherboard, but typically one will be the norm for laptops and desktops. Servers are another matter—large memory systems such as those built using expansion standards like Compute Express Link (CXL) will have hundreds of modules in a system with multiple modules on a board.

CAMM Adoption

CAMM standards are relatively new and motherboards and systems that utilize CAMMs instead of DIMMs are also scarce at this point. However, this is expected to change rapidly over time given the higher performance, capacity, and functionality of CAMMs.

CAMMs will be a boon to embedded developers that can take advantage of the increased capacity and performance, as well as their superior cooling and more rugged connections and mountings. Screws are our friend when replaceable modules come into play. They’re significantly more robust than DIMM connectors and the standard form factors are amenable to the many different cooling technologies available to designers.