VITA 93 QMC is a Mezzanine Standard for All

What you’ll learn:

- What is the VITA 93.0 QMC standard?

- Why VITA 93.0 QMC is important.

- Why VITA 93.0 QMC is for more than military and avionics.

VITA’s VITA 93.0 QMC small-form-factor, mezzanine card (MC) standard comes out of the military and avionic standards realm, but it’s ideal for almost any embedded platform that has rugged requirements. It’s comparable to the popular M.2 standard with two major differences:

- Higher-speed, rugged connectors with mounting holes to provide better support in rugged applications.

- Better scalability. QMC also addresses many applications that use Mini-PCIe modules.

The standards define a more compact and high-speed alternative to some of the existing rugged mezzanine standards such as VITA 57 FMC and VITA 42 XMC. They’re designed to provide support for high-performance FPGAs, GPUs, and artificial-intelligence/machine-learning (AI/ML) accelerators as well as storage. They deliver optimal size, weight, and power and cost (SWaP-C) solutions.

VITA 93 QMC Basics

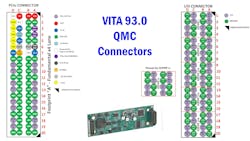

M.2 modules have different edge connector pinouts while QMC uses a pair of mated connectors (Fig. 1). VITA 93.0 defines the placement and signals for the two connectors as well as the space available for components on the top and bottom. The four mounting holes ensure reliable operation in high shock and vibration environments. The connectors are designed to handle high-speed signals such as PCI Express (PCIe) Gen 5.

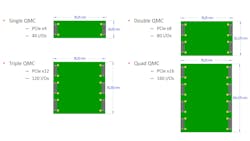

One major difference compared to other mezzanine and peripheral expansion-card definitions is scalability. The standards define one or more slots (Fig. 2) versus something like M.2, which defines different lengths.

The QMC approach provides more bandwidth as each slot has a set of connectors. It also means that a carrier board with more than one slot can accommodate a mixture of QMC cards. A two-slot configuration can handle two single-width cards or one double-width card. The latter has more than twice the area available to a designer compared to two single-width cards.

The pair of connectors includes a PCIe side and a general I/O connection designed for high-speed serial communication that’s typical for most applications (Fig. 3). This provides a standard QMC interface as well as custom connections. The I/O connector is organized as five IOPIPEs already used in other VITA VPX standards. Each includes four differential pairs with matching ground connections or eight single-ended signals. A quad QMC card has 160 I/O connections.

The definitions include 3.3- and 12-V DC power. There’s a JTAG interface and an I2C interface for card management.

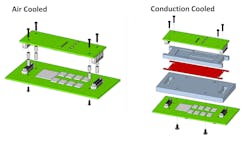

QMC cards can be air- or conduction-cooled (Fig. 4). Standoffs are mounted on the carrier; air-cooled solutions can use a heatsink. Conduction-cooled implementations incorporate the card with a heatsink, which mates with a cooling structure. The two have thermal interface material provided by the carrier manufacturer. Mechanical envelope definitions are very tight to maximize interchangeability and reliability.

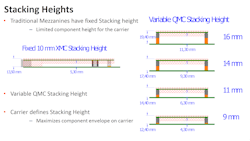

Most mezzanine standards have a fixed stacking height. For example, the XMC standard limits the overall height to 13.5 mm and headroom beneath the card must be 5.3 mm. The QMC standards are more flexible, providing variable stacking specifications (Fig. 5). The actual limits on the QMC card remain unchanged, but the area underneath has a height restriction based on the connectors employed on the carrier board.

The QMC cards are designed to work with front- and rear-I/O systems. This is important for many military and avionics systems based on other VITA standards like OpenVPX.

VITA 93 For Non-Military and Avionics Applications

VITA standards were crafted for military and avionic applications that require the reliability and long-term support provided by vendors. The connectors used for OpenVPX 3U and 6U boards are expensive and designed to handle not only the rugged environment, but also the high-speed connections needed for more demanding applications.

The VITA 93 QMC modules will work well in such environments. We’re likely to see QMC slots on carrier cards and single-board-computer (SBC) cards to provide everything from storage to AI/ML acceleration.

Multiple QMC slots will fit on a 3U OpenVPX board. QMC cards can also populate other cards like PC PCIe cards. Designers will likely prefer QMC cards to alternatives like M.2 and Mini-PCIe for applications like industrial vehicles and commercial drones where consumer-oriented modules are less desirable. The cost for the connectors is a small part of a solution, making QMC cards economically viable compared to military and avionics versions that simply come with more certification and testing.

Rapid Development of VITA 93

It’s worth noting how quickly the VITA 93 standard came about. A study group was started in July 2022 and a detailed report was available in 2023 when a working group was started. Presentations at the 2025 Embedded Tech Trends conference highlighted working examples that will meet the finalized standards.

The various standards associated with VITA 93 are still working through the finalization stage. They’re very detailed, addressing not just the connectors and pinouts but also details like cooling and form factors.

Part of the reason for the quick development was the starting point and cooperation of the major players in this industry. Likewise, the applicability of QMC for industrial and commercial applications was considered.

There’s more to come with the VITA 93 QMC mezzanine standard, but hopefully this gives you a good handle on what it can do and why you should be looking at it—going beyond military and avionics applications.