Applying Ceramic Tech to Achieve High Power Density (Part 2)

This article is part of the Power Management Series: Delving Into Power Density. This article is also part of the TechXchange: Charging Capacitors.

Members can download this article in PDF format.

What you'll learn:

- What are the main characteristics of ceramic capacitors.

- Benefits of Kemet's KC-LINK caps.

- Ragone plots: What are they and what do they reveal?

In Part 1, we determined that Class I (including C0G, NPO, and U2J types) multilayer ceramic capacitors (MLCCs) were better than Class II. Class I exhibits high temperature stability, high ripple-current capability, and low loss, thus making these types of capacitors a designer’s first choice in high-power-density applications.

Dielectric Energy-Storage Ceramics

Ceramic capacitors will function as a passive component, which possesses a high power density of GW/kg.7 These devices exhibit the following characteristics:

- A fast charge–discharge speed is in microseconds, with some ceramic capacitors even in nanoseconds.

- Good fatigue endurance greater than or equal to 106 cycles.

- High temperature stability, which is an essential function for solid-state power systems.

Let’s look at the latest Class I solutions that can help designers achieve higher efficiency in their designs.

Enter the High-Power-Density KC-LINK Capacitors

Kemet has some of the most innovative capacitor technologies in the industry. What are the strengths of Kemet’s KC-LINK capacitors, especially in conjunction with fast-switching wide-bandgap (WBG) semiconductor devices? WBG devices push the envelope of operation with higher voltages, frequencies, and temperatures.

The unique KC-LINK capacitor has a very low effective series resistance (ESR) and quite low thermal resistance. These capacitors can also function well at very high ripple currents with no change in capacitance versus dc voltage.

As a bonus, these devices only experience a negligible change in capacitance versus temperature. They offer an excellent operating temperature of 150°C, and thus may be mounted quite close to fast-switching semiconductors in high-power-density applications requiring only minimal cooling.

This class of capacitor is also well-suited for power converters, snubbers, inverters, and resonators when high efficiency is needed in a design.

Making Capacitors Smaller

Miniaturization of capacitors can be directly related to improved energy and power density. This is determined at the component and material levels for multilayer ceramic, polymer film, and electrolytic classifications.

The volumetric efficiency of capacitors depends upon the capacitance value, equivalent series resistance (ESR), and operating voltage.

Power density values will greatly span from 108 W/cm3 at the material level, and on through to the application level of 50 W/cm3 at the inverter level.

Ragone Plots

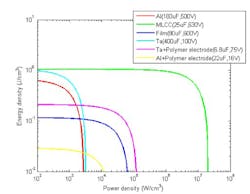

Ragone plots are important for benchmarking energy and power densities, and they’re often considered for energy-storage devices including batteries, flywheels, and ultracapacitors (see figure). The energy density is defined as the amount of stored energy per volume in the device.

The Ragone curves for capacitors are typically represented with the stored energy (EC) as a function of power (P):9

In these equations, C represents the capacitance and R is the internal resistance; UC,0 is the initial capacitor voltage. Maximum power is:

which can be attained for Ec→ 0.

Summary

Energy density and power density are two of the most important metrics for capacitors. These values will significantly diminish as the operating voltage is reduced to ensure reliability under extreme operating conditions. As a result, designers are seeking to develop new high-temperature materials to increase overall capacitor performance.

Read more articles in the Power Management Series: Delving Into Power Density, as well as in the TechXchange: Charging Capacitors.

References

1. “What Ceramic Technologies are Best for High Power Density Applications? Part 1,” Kemet.

2. “What Ceramic Technologies are Best for High Power Density Applications? Part 2,” Kemet.

3. “Excellent energy density and power density achieved in K0.5Na0.5NbO3-based ceramics with high optical transparency,” ScienceDirect.

4. “Electrical characteristics of high energy density multilayer ceramic capacitor for pulse power application,” IEEE Xplore.

5. “High energy storage density and power density achieved simultaneously in NaNbO3-based lead-free ceramics via antiferroelectricity enhancement,” Journal of Materiomics, 2021.

6. “Remarkably enhanced dielectric stability and energy storage properties in BNT–BST relaxor ceramics by A-site defect engineering for pulsed power applications,” Journal of Advanced Ceramics, 2022.

7. “Progress and perspectives in dielectric energy storage ceramics,” Journal of Advanced Ceramics, 2021.

8. “Here’s what makes MLCC Dielectrics different,” Kemet, 2019.

9. “Energy and Power Densities of Capacitors and Dielectrics,” Materials Research Institute, Penn State University, Energy Systems Division, Argonne National Laboratory, 2015.