Advanced Numerical Simulation for Hybrid and Electric Vehicles

With concerns over air pollution and petroleum supplies, the use of hybrid electric vehicles (HEVs) and electric vehicles (EVs) have come to the forefront as alternatives to conventional gasoline and diesel engines. Governments worldwide are promoting HEV/EV research. The United States government has announced $2.4 billion in funding for new designs of battery packs, electric motors and other components, setting the goal of 1 million HEVs on the road by the year 2015 [1]. The U.S. Department of Energy predicts that by 2030, alternative vehicles will comprise 28% of the total U.S. light-duty cars and trucks — a 20 percent increase from 2005 [2].

These increased demands for HEV/EV applications have spurred intense competition to develop improved and cost-effective electric powertrains. The potential payoff is enormous in such development efforts, as are the business risks in going to market with flawed, inadequate or suboptimal designs.

Clearly, a revolution is underway in automotive technology. The responsibility for leading the charge has been placed squarely in the hands of automotive engineers, who must completely rethink how they approach powertrain design. For engineers at automakers as well as suppliers of major subsystems and components, the challenge is to conduct a massive amount of research and development on an entirely new generation of powertrains in a highly compressed timeframe.

In meeting these demands, leading automotive companies with HEV/EV initiatives are focusing on development efforts driven by simulation rather than outdated methods of trial-and-error prototype testing. Indeed, effective implementation of advanced numerical simulation will likely separate winning organizations from less adept competitors in the race for designing the next generation of improved electric powertrains.

Numerous software solutions are available for the diverse types of analysis needed in such development work including mechanical, electrical, electromagnetic, electrochemical, fluid and thermal management applications. Often, these separate packages are not entirely compatible, hampering engineers in efficiently using the full range of technologies in arriving at optimized electric powertrain designs. A better alternative is to implement a full range of these technologies as an integrated suite of best-in-class software operating in a single unified environment.

Major Challenges Facing HEV Powertrain Designers

Today’s automotive engineers are challenged with designing new electric powertrain technologies almost entirely from scratch. Key components included in this task are electric battery packs, electric traction motors/generators and power electronics. The design of these HEV components involves complex physical problems and an enormous amount of challenging system integration. Listed below are some of the challenges involved in developing individual components as well as relevant considerations of electromagnetics with regard to EMC/EMI.

BatteryPacks

Electric batteries in HEV/EVs perform the double duties of providing primary drive power for the vehicle as well as energy for numerous electric-powered auxiliary systems. Therefore, they must meet the same reliability, durability and affordability standards set by petroleum fuel cars — beyond that, they must provide orders of magnitude more energy than conventional batteries.

As engineers design batteries with large energy capacity and increased power output, they must consider the thermal, structural and electromagnetic influences on the battery pack as well as the cells within. For example, batteries generate heat while charging and discharging. The temperature of all cells within the battery pack must be strictly maintained within a few degrees C of each other. Otherwise, harmful internal current loops can form within the pack, which can drastically shorten battery life. This necessitates a cooling system — whether by air or liquid — and sometimes creates a side challenge of minimizing noise close to the passenger cabin. Drivers of HEV/EVs expect an ultra-quiet driving experience, not the - loud hum of a cooling system.

Engineers must also take into account the physical placement of an electric battery pack within an HEV as well as stresses the battery will experience under a range of driving conditions. The battery must be designed to safely withstand multiple variables such as external heating, over-charging, over-discharging, nail penetration, crush or external short. The same safety goals apply to crash scenarios, in which passengers must be protected from toxic acids released from the battery during such an event.

Motor/Generator

For years, automakers invested relatively little time and money in electric machine design (that is, the electric traction motor/generator) because the internal combustion engine was so widely used. These conventional engines accomplished what they needed to: Consumer requirements were met, emissions regulations were not as stringent, and oil prices were not a concern. Today all that has changed, with a huge amount of interest in new motors and a correspondingly huge pressure on companies to develop the most efficient, cost-effective electric design. Brainpower and investment dollars are flowing into this area, and the electric motor, just as with the electric battery pack, poses its own set of design challenges.

The motor/generator plays an essential role in the propulsion of the vehicle. It also recharges the batteries via regenerative braking. HEV/EV traction motors are different from all other motors because they must work reliably in a very demanding physical environment. Motors must operate consistently under extreme hot and cold temperatures, severe vibrations, hard duty cycles and rough road conditions. In an HEV, an electric motor is also exposed to high temperatures produced under the hood by the engine. All of these variables must be thoroughly addressed in motor design. Reliability is a crucial selling point for auto customers; poor engine performance increases warranty costs and quickly degrades a vehicle brand.

Customers also expect high fuel efficiency from HEV/EVs. Fuel efficiency, low emissions, safety and performance drive consumer purchasing decisions and, therefore, directly affect market success. Because the electric motor design determines how much electrical energy provided by the battery is transformed into physical energy used to run the vehicle, designing a highly fuel-efficient motor is one of the most important challenges HEV/EV powertrain engineers face today.

Power Electronics

Power electronics are equivalent to the combined heart and the brain of an electric powertrain system. They must precisely control the power transfer between the battery and the motor/generator and also implement the logic to adjust the powertrain to various driving conditions and driver inputs. To operate at the highest efficiency under a variety of driving conditions, power supplied to the traction motor needs to be carefully controlled at a relatively high switching frequency through devices such as insulated gate bipolar transistors (IGBTs) via feedback continuously received from sensors monitoring the motor for position, speed, temperature, and other information.

Thermal management is a major concern for power electronics in HEVs. All of the power delivered by the electric powertrain to the wheels, as well as the power needed to recharge the battery, has to travel through the power electronics. Therefore, even the slightest power loss in the electronics creates a large amount of heat. The heat needs to be carefully managed and dissipated under a wide range of operating conditions, such as driving in a hot desert or in subzero winter conditions, to avoid heat damage to the power electronics and nearby components. Optimally, the electric losses in the electronics need to be accurately calculated, and heat dissipation paths need to be identified and designed to ensure effective cooling.

EMI/EMC

One of the primary challenges in power electronics development is management of electromagnetic interference and electromagnetic compatibility (EMI/EMC). Since the power supplied to the motor needs to be controlled at relatively high switching frequencies, the EMI between the various electrical components becomes an important concern. If EMI is unaccounted for, it will destroy signals and prohibit the motor from operating. Therefore, EMI effects need to be carefully studied and accounted for in the control logic. This requires a comprehensive study of the electromagnetic fields in and around the motor, busbars, and nearby components while these components are operating in an interconnected, coupled way as in real-life.

Putting Simulation Technology To Work

Multiphysics simulation software allows engineers to understand how a design will perform under various loading conditions before prototyping takes place. Not only can physical, real-life scenarios be modeled with accurate simulation, but the effects of and interactions between fluids, mechanics, thermal physics, electrochemistry and electromagnetic forces can be simulated and the design adjusted based on those models. In this way, designs can be generated faster and systems can be optimized up front in the cycle to avoid surprises and problems that might occur in the later stages of product development.

Simulation tools for HEV/EV development span a wide range and include mechanical, fluid dynamics, thermal, electrical and electromagnetic issues. These tools can be used in tackling the challenges of developing individual powertrain components — electric battery packs, electric traction motors/generators and power electronics — as well as the tremendous complexities when these subsystems are integrated into the complete vehicle powertrain.

Battery Pack Simulation

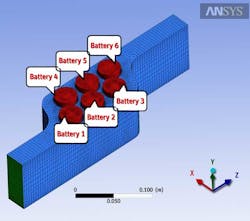

Battery thermal management is a top priority in HEV/EV development; the goal is to avoid overheating, which reduces power-generating efficiency and shortens battery life. For cylindrical cells, engineers typically employ an air cooling strategy that uses pack housings shaped for optimal cooling; a blower and guiding vanes provide an adequate airflow. For rectangular cells, cooling generally is done with liquid circulating through heat exchanger elements in contact with cells. A control algorithm = varies the loads on different cells based on temperatures and charger status.

Related Articles

• Use Thermal Analysis And Other Types Of Simulation To Craft A “Cool” Design

• Thermal Analysis and Other Simulation Types

• MOSFET Thermal Simulation Tool Extends Simulation Accuracy

In evaluating and optimizing the various thermal management configurations, parameterization and methods such as design of experiments are used in combination with fluid dynamics solvers for analyzing the complex 3-D cooling flows and conjugate (solid-to-fluid) heat transfer. For evaluating pack performance for long driving cycles, the linear time invariant (LTI) method is useful for efficiently performing such real-time simulations (Fig. 1).

Engineers can apply electronics circuit simulation technology in evaluating the control algorithms for studying overcharging, high-current charging/discharging, external shorts or other electrical problems that could reduce battery life and risk battery explosion. Software is ideal for studying such algorithms due to its ability to tightly integrate 3-D physical models (fluid dynamics and mechanical) into the control circuit simulation.

Structural mechanics software comes into play for solving structural problems caused by incidents such as a crash or foreign body penetration of the battery pack. It evaluates the structural integrity of the assembly to determine if the escape of toxic battery contents can be prevented or if damage to cells would cause thermal runaway and battery explosion. Such virtual prototyping is also useful in studying vibrations as well as durability and fatigue life of the battery pack.

Motor/Generator Simulation

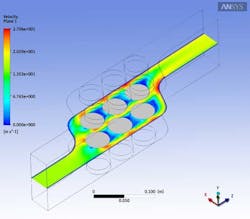

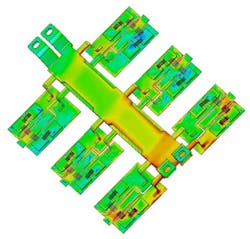

In developing the motor/generator, the design team must focus considerable attention on the electromagnetics of this electric machine. From initial CAD drawings and related engineering specifications of the assembly, electronics design optimization software defines the main elements of the motor/generator including magnet materials, coil configurations, number of turns, air gaps and more. Parasitic extraction tools compute the machine’s electrical properties.

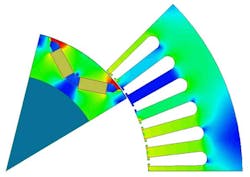

These outputs are typically entered into electromagnetic field simulation software, which computes the torque profile of the machine (Figs. 2 and 3). It figures out how the torque ramps up over time for driving the vehicle in motor mode and also computes the electrical resistance for stopping the vehicle in brake mode. Vehicle weight is brought into the analysis to determine acceleration as well as stopping time for various scenarios. Based on this output, the team can then modify the design by changing any of the basic design parameters (magnet size, for example) to balance machine performance against its size, weight and cost.

The computed torque output may be used further in structural mechanics software for computing stresses, loads, deformations and vibrations of the physical parts of the powertrain including the driveshaft and gearing. Vibration analysis is important because tractions can be a promiment source of noise in EVs, which as mentioned are expected to be quiet by nature. Fluid dynamics analysis is useful for studying thermal management issues, mapping energy losses, and determining heat distributions in the motor/generator assembly.

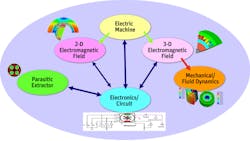

Throughout the electromagnetics and mechanical development processes, integrated multiphysics software coordinates the actions and exchanges of data between the various tools in the many computations performed for different load scenarios and in comparing various design alternatives. This multiphysics cosimulation process is facilitated by the software all running on a single unified environment with a smooth flow of data between programs.

Power Electronics Simulation

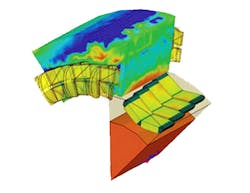

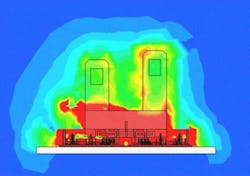

For thermal management of the HEV power electronics, engineers enter representations of IGBT characteristics (switching voltages, current waveforms, etc.), control algorithms (for turning the IGBT on and off) and the motor/generator into power electronics circuit simulation software for virtual analysis (Fig. 4). From this data, the software determines how the levels of electrical current flowing through the entire system vary at given times for vehicle acceleration, cruising and braking.

Using electronic thermal current tools, engineers then specify the geometry of the major heat sources in the powertrain system (IGBTs and current-carrying parts of the motor/generator). Through parametric analysis, each heat source is applied individually at major points of interest in the system, with air circulation and conducted thermal energy taken into consideration. The software then processes this data and generates a thermal model, which engineers use to determine overall temperature profiles of each IGBT together with temperature-dependent performance variables, such as energy drained from the batteries to ensure that heat levels do not exceed specified limits to adversely affect IGBT performance.

From this temperature profile, engineers can utilize the thermal–structural analysis capabilities of FEA software to determine the resulting thermal stresses. Electronic design analysis tools can be applied to calculate electromagnetic forces acting on motor/generator components to determine deformations and mechanical stress distributions on the structure. Engineers can then modify the structure to eliminate stress concentrations and excessive deformation, or conversely, to lighten regions that may have been overdesigned with excess material.

EMI/EMC Simulation

In HEV/EV development, switching speeds of IGBTs ranging from tens to hundreds of kHz — with turn-on rise times and turnoff fall times in the order of 50 nanoseconds to 100 nanoseconds — can cause two major electromagnetic problems. Conducted emissions (through current-carrying structures) can cause power integrity issues or set up reflected waves of energy that can potentially damage the inverter and the motor. Radiated electromagnetic fields (through air) can affect the rest of the vehicle’s many electronic systems. Both types of interference problems must be considered. Engineers must design for electromagnetic compatibility/electromagnetic interference (EMI/EMC) in vehicles (Fig. 5).

To accurately characterize the behavior of a switching device such as an IGBT, engineers typically begin by using a parameterization wizard that takes into account performance curves and tabular data from vendor-supplied specification sheets. This process automatically extracts the required parameters to aid in creating a semiconductor circuit model of the IGBT.

Next, the physical layout of the power inverter is imported from CAD geometry into parasitic extraction software, which then computes the frequency-dependent resistance, partial inductance and capacitance (RLC) along the conduction paths. The tool then creates an equivalent circuit model for system simulation.

Results of these simulations can be used to examine radiated emissions, enabling engineers to calculate the field intensity at any given point in space to determine if the inverter package is in compliance with federal and international standards. If allowable limits are exceeded, EMI/EMC problems in the inverter system can be traced to the source in the physical layout of the device. The design can then be parametrically varied and a series of simulations performed until conducted and radiated electromagnetic emission levels are acceptable.

System Integration

System integration is perhaps the greatest challenge in electric powertrain development. Each component of the electric powertrain has unique characteristics, attributes, strengths and other complexities that must be taken into account. The objective is to ensure that the entire electric powertrain performs at the highest overall efficiency under a wide variety of loads and operating conditions experienced in real-life driving scenarios. Since subsystems and components work together in a coherent, tightly coupled way, they cannot be developed entirely in isolation from one another. Rather, the performance of each subsystem must be carefully matched with those of all others.

To successfully simulate such complexities in the HEV/EV powertrain, simulation solutions must be in the form of an integrated platform capable of multidimensional, multiphysical and multiscale simulation, providing the technology needed in addressing the many mechanical, fluid, electrical, electrochemical and electromagnetics issues of these complex powertrain systems (Fig. 6).

Moving Ahead Of The Competition

The pace of HEV/EV development is incredibly fast, with OEMs and suppliers alike having to meet challenging demands in a market with huge potential gains for cutting-edge companies — and monumental risks for stragglers. In this intense environment, automotive engineers are challenged with designing extraordinarily complex next-generation electric powertrains within demanding timeframes that cannot be met using the slow and inefficient trial-and-error prototype testing methods.

Instead, multiphysics-based simulation-driven development must be used to balance the intricate, interdependent and often conflicting mechanical, electrical, electromagnetic, fluidic and thermal management requirements.

Such an approach allows design teams to efficiently evaluate hundreds of alternatives within multiple domains, conduct numerous what-if studies, predict vehicle behavior in real-life driving scenarios, and optimize final designs faster than is otherwise possible. The process enables engineers to best develop the batteries, motor/generators, power electronics, and other various components — and to tightly integrate these diverse parts so they all work together in a coherent, coupled manner.

The key to such an optimal powertrain design is a multiphysics-based simulation solution in which the different software programs all work together in an equally integrated and coupled manner. Piecing together fragmented and otherwise separate and often incompatible programs simply won’t make the grade in such complex applications. As the demand for HEV/EV continues to grow, a simulation solution with the breadth and depth of multiphysics technologies is not only a competitive advantage but an absolute necessity for companies that want to stay in the game.

References

1. Http://www.whitehouse.gov/blog/09/03/19/Electric

2. Annual Energy Outlook 2007 with Projections to 2030, Report DOE/EIA – 0383 (2009).

3. J.S. Hsu, C.W Ayers, C.L. Coomer, R.H. Wiles, S.L. Campbell, K.T. Michelhaugh, “Report on Toyota/Prius Motor Torque Capability, Torque Property, No-Load Back EMF, and Mechanical Losses”, Oak Ridge National Laboratory, Oak Ridge Institute for Science and Education, ORNL/TM-2004/185.

4. S. Stanton, D. Lin, Z. Tang, “Interior Permanent Magnet Machine Analysis Using Finite Element Based Equivalent Circuit Model”, IEEE Vehicle Power and Propulsion Conference 2009 proceedings pages 291-294, ISBN 978-1-4244-2600-3.

Scott Stanton is the Technical Director for Advanced Technology Initiatives at ANSYS, Inc. He has spent a combined 13 years of his career at ANSYS and Ansoft Corp. working with customers throughout the U. S., Europe and Asia in the modeling and simulation of electromechanical devices and systems such as: motors and drives, solenoids, sensors, transformers and actuators. Before joining Ansoft, Scott worked six years for Westinghouse Electric Corporation in the Power Generation Controls Group as well as the Industrial Automation and Drives Group. He holds a B.S. degree in electrical and computer engineering from Ohio University.

Sandeep Sovani, PhD, is Manager of Global Automotive Strategy at ANSYS Inc. Sandeep serves as a leader for the automotive industry sector at ANSYS and is responsible for developing the company’s business and market strategy for the worldwide automotive market segment. He holds a B.E in Mechanical Engineering from University of Pune, India, M.Tech., from Indian Institute of Technology Chennai, India and Ph.D. from Purdue University. Dr. Sovani has been actively involved in various areas of automotive technology and business for two decades. Dr. Sovani previously worked with Tata Motors, India. Under a grant from the Cummins Engine Company, he has conducted research on IC Engines at Purdue University and recently served as an Adjunct Professor of Engineering at Lawrence Technological University in Michigan.