Distributed-power architectures now dominate in power-system designs for high-performance datacom and telecom networks, as well as data-center equipment. The change from centralized power—a simple ac-dc power supply, perhaps with battery backup, feeding the cards in a system rack—came about by necessity. Semiconductor operating voltages decreased as ever-smaller process nodes were developed to boost the processing power of ICs. The ICs became more powerful and their lower operating voltages demanded higher current.

This file type includes high resolution graphics and schematics when applicable.

On top of that, long printed-circuit-board (PCB) tracks would mean unacceptable I2R losses, reducing power system efficiency. As a result, distributed-power architecture became the norm—a trend that continues today. Since the 1980s, the power demands of data centers have risen from 300 to 1200 W per board, and some forecast that it will reach 5 kW in 2015 as network IP traffic skyrockets over the next few years.

The economics of creating distributed-power systems were transformed back in 1984, when a group within Sweden's part of Ericsson AB, Ericsson Components – RIFA Power (later to become Ericsson Power Modules), launched the PKA series of dc-dc converters. The introduction of the PKA, described by Ericsson as “the world's first high frequency dc-dc switching power supply,” meant that engineers no longer had to design relatively expensive and complex circuits from discrete components. They could now use a compact board-mounted module on each card, adding just a few external filtering and decoupling components, to create much more efficient and effective power systems.

The use of power modules also significantly improved system reliability. This was particularly important for those designing communications networks, where the target for operating life was sometimes 25 years or more.

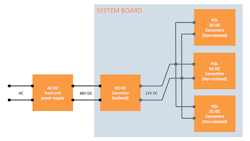

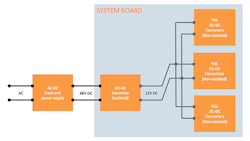

Typically, the front-end ac-dc unit would have a –48-V output, and a dc-dc power module on each card would convert this to 12 V or 5 V, or a combination of both, to provide the correct operating voltage for semiconductors in the system. Then, 3.3-V semiconductors started to appear, and today we're down to 0.9 V for many with some processors drawing up to 90-A current at full load (Fig 1).

The larger the differential between the input and output voltage(s) of a dc-dc converter, the less efficient the conversion process. It soon became clear that to achieve maximum system efficiency, it’s best to handle the last conversion very close to the load, i.e., the processor, FPGA, or other device. Power supplies used in this final conversion are point-of-load (POL) converters. In addition to boosting efficiency, placing power converters as close as possible to their loads prevents instability due to stray impedances in long PCB tracks or system wiring. Datel, which was acquired by Murata as part of the Power Electronics Division of C&D Technologies in 2007, was an early pioneer of isolated dc-dc converters and POL modules during the 1980s and 1990s.

Distributed-power architectures can be implemented in a number of different ways, using regulated or unregulated bus voltages. About 15 years ago, as systems became more complex, demanding a number of different voltages (perhaps 12, 5, 3.3, 2.5 and 1.2 V), power-system designers began to adopt intermediate bus architectures (IBAs). Here, the ac-dc power supply feeds an IBA converter at perhaps 24 V or –48 V. The isolated IBA converter outputs 5 to 14 V dc and feeds the required number of POL converters (Fig 2).

Distributed Goes Digital

The demand to provide sophisticated power-management functions, including the sequencing of power supplies with controlled ramp rates as required by large FPGAs, along with a desire to reduce board space and the number of external components, drove more and more power-system designers to digital power over the past decade. Key to this movement are power-management ICs from companies like Texas Instruments, which in December 2002 introduced the industry’s first digital-signal-processing (DSP) development kit specifically geared to power-supply applications.

What’s accelerated adoption of digital power over the last five years, though? Simply put, it’s the development of off-the-shelf digital power-converter modules. Digital converters have much in common with their analog counterparts, including similar power switches and output filters. However, the inner control loop provides digital flexibility for tailoring power delivery to the application, as well as enabling power systems to dynamically adapt to changes in operating conditions in real time. Communications, monitoring, and control are implemented over the industry-standard PMBus.

Digital control is particularly important in improving the efficiency of data-network power systems. Networking equipment draws more power with greater data throughput. At times of low data traffic, the network operates well below capacity, power supplies operate well below their maximum load, and processors can run at lower clock speeds.

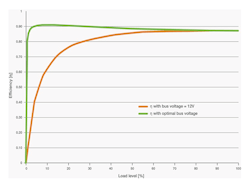

At low loads, the power supplies are relatively inefficient, resulting in excessive energy consumption and waste-heat generation, with undesirable technical, financial, and environmental consequences. By implementing a digital control loop encompassing both an intermediate bus and POL converters, the intermediate-bus voltage can be varied dynamically in response to varying loads. The input voltage to the POL converters is reduced under low load conditions, which increases conversion efficiency at low loads (Fig 3).

Some digital power devices offer a dynamic-voltage-scaling (DVS) function to save energy. If the demand for computing power is low, the processor’s clock frequency and its supply voltage can be reduced. DVS is usually implemented as an open-loop function with a lookup table holding pre-determined combinations of frequency and supply voltage.

More advanced than DVS, adaptive voltage scaling (AVS), adopts a closed-loop, real-time approach that adapts the supply voltage precisely to the minimum required by the processor, depending on its clock speed and workload. This technique also compensates automatically for process and temperature variations in the processor.

Most switching power supplies use a closed control loop with negative feedback from output to input. A compensation network is needed to adjust the loop’s frequency response to achieve the optimum transient response without compromising stability. The design of the compensation network can be a time-consuming task involving considerable trial and error. Even then, the performance of the components in the network can change with variations in temperature or due to aging. In 2010, CUI Inc, a North American company, was the first manufacturer to develop and launch non-isolated POL converter modules featuring auto-compensation, a digital function that completely eliminates this problem.

Using digital power modules also simplifies or enables many other aspects of power system design. These include active current sharing, voltage sequencing and tracking, soft start and stop, and synchronization.

The Drive for Standardization

Wider adoption of dc-dc power modules has led to a greater push toward some level of standardization of products from different manufacturers. Due to concerns about supply-chain reliability, customers demanded second sources for products, leading to trade associations being formed by power-supply and component vendors.

As has often been the case, though, the alliances formed in this space succeeded in little more than agreeing to standard footprints and pin-outs for certain categories of power converters, such as non-isolated and isolated dc-dc converter modules. While this enabled a degree of interchangeability between products from different manufacturers, there hasn’t been full consensus on how to implement all of the electrical functions of converters, making it less than straightforward to swap out one product for another. This is particularly true for digital power, which adds another layer of complexity to the challenge of ensuring compatibility between solutions.

More significantly, in 2004, Artesyn Technologies, Astec Power, and a group of semiconductor suppliers—Texas Instruments, Volterra Semiconductors, Microchip Technology, Summit Microelectronics, and Zilker Labs—formed a coalition to develop an open standard for communications with a protocol dedicated to power systems. This was the birth of the industry standard for the power-subsystem management known as PMBus.

Not all has been “clear sailing,” though, and despite good intentions and a number of positive moves, various issues stalled developments by other manufacturers. Most notable was the patent-infringement lawsuit issued by Power One in 2005, intended to protect the Z-Bus technology used in its POL regulator ICs for monitoring and controlling power supplies. This held back the widespread adoption of PMBus for around four years, until the use of licensing royalty agreements became routine for such technology.

More recently, power-supply companies have been coming together once again to address these issues, particularly the more challenging requirements of digital power. In July 2011, CUI announced a cooperative agreement with Ericsson Power Modules, and in September of that year, demonstrated a new family of POL modules that are pin- and-function compatible with Ericsson's BMR46X series of converters.

A year later, CUI entered into a license agreement with Ericsson for the latter’s 3E Advanced Bus Converter family, allowing it to offer customers an intelligent intermediate bus converter to pair with its portfolio of POL products. The companies agreed at that time to cooperate on a common standard for digital intermediate-bus converters going forward. Then, in July 2014, Murata and Ericsson announced a technical collaboration agreement—their goal is to accelerate the adoption of digital power products by offering customers fully compatible products from each company.

Meeting Future Needs

According to the Ericsson Mobility Report, annual IP traffic will reach 7.7 zettabytes by the end of 2017, up from 2.6 zettabytes in 2012. Video communications, cloud-based services, and the interconnection of physical objects, dubbed the Internet of Things (IoT), are the primary drivers of this unstoppable growth. This will place even greater demands on data-network power-system designers. They must fully exploit the functional and efficiency benefits provided by digital-power devices in order to meet this challenge.

This file type includes high resolution graphics and schematics when applicable.

Furthermore, the technology that started in datacoms and telecoms is spreading out into other industries and applications, such as in medical, industrial, and test/measurement equipment, as advanced processors and FPGAs become commonplace. This creates the need for a simple, intuitive, multisource solution across the board. The challenge is to achieve “perfect power conversion, under all conditions, all of the time.” Hence, power-supply manufacturers are under greater pressure to accelerate their rate of innovation, to the extent where they must rely on much deeper collaboration.

References:

Compensation Methods in Voltage Regulators

About the Author

Martin Hägerdal

Spokesman/President

Martin Hägerdal, Architects of Modern Power Spokesman and President Ericsson Power Modules, has 15 years of experience in the telecom industry; five years of R&D experience and 10 years in various sales positions. As a R&D engineer, Martin managed projects for the commercialization of 3G technology. He has held several management positions within the Ericsson AB sales organization, over four continents, and currently serves as President and Corporate Vice President of Ericsson Power Modules, Ericsson AB. Martin holds an MSc degree in electrotechnical engineering from Lund Institute of Technology and a BSc in business administration from Stockholm University.

Steve Pimpis

Spokesman/Vice President, Global Strategic Product Marketing

Steve Pimpis, Architects of Modern Power Spokesman and Vice President, Global Strategic Product Marketing at Murata Power Solutions with over 20 years of experience as a sales and marketing leader in the electronics industry, was recently appointed as VP and GM of the Front End and Board Mount Power Business units. Steve previously worked at Power-One as director of product marketing management, and I-Systems as VP marketing and sales, where he developed the initial product roadmap for the startup company as well as conceptualizing the design and functionality of the equipment. Upon graduation from college Steve worked for AT&T/Lucent Technologies as a manufacturing engineer in the telecom transmission equipment business. Steve graduated from Texas Tech University with a master’s degree in engineering, after completing his BSc in engineering at the University of Massachusetts, Lowell.

Mark Adams

Senior Vice President

Mark Adams, with CUI since 2009, has over 20 years of industry experience. He has been instrumental in the reorganization of the company’s sales structure and CUI’s movement into advanced power products. Prior to CUI, Mark was a Sales Director at Zilker Labs for the three years leading up to its acquisition by Intersil. During his time at Zilker Labs, he was able to secure numerous design wins at some of the largest communication OEMs in the world, as well as power-supply companies and reference designs for complicated semiconductors requiring specialty power needs. Mark also spent seven years as a manufacturer representative primarily supporting Xilinx FPGAs. Mark entered the FPGA market during its transition from being primarily ASIC-driven to a market driven by FPGAs and application-specific products. Mark also has seven years of distribution experience with Future Electronics.

Mark attended Central Washington University, where he studied business marketing; received his commission from Army ROTC; and served in the Army National Guard for 13 years.